Self-balancing liquid pumping device, hydraulic filling type evaporation device and refrigerating system thereof

An evaporating device and self-balancing technology, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as difficult to effectively control the height of the liquid level, low precision of pump liquid control, and complex overall structure of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

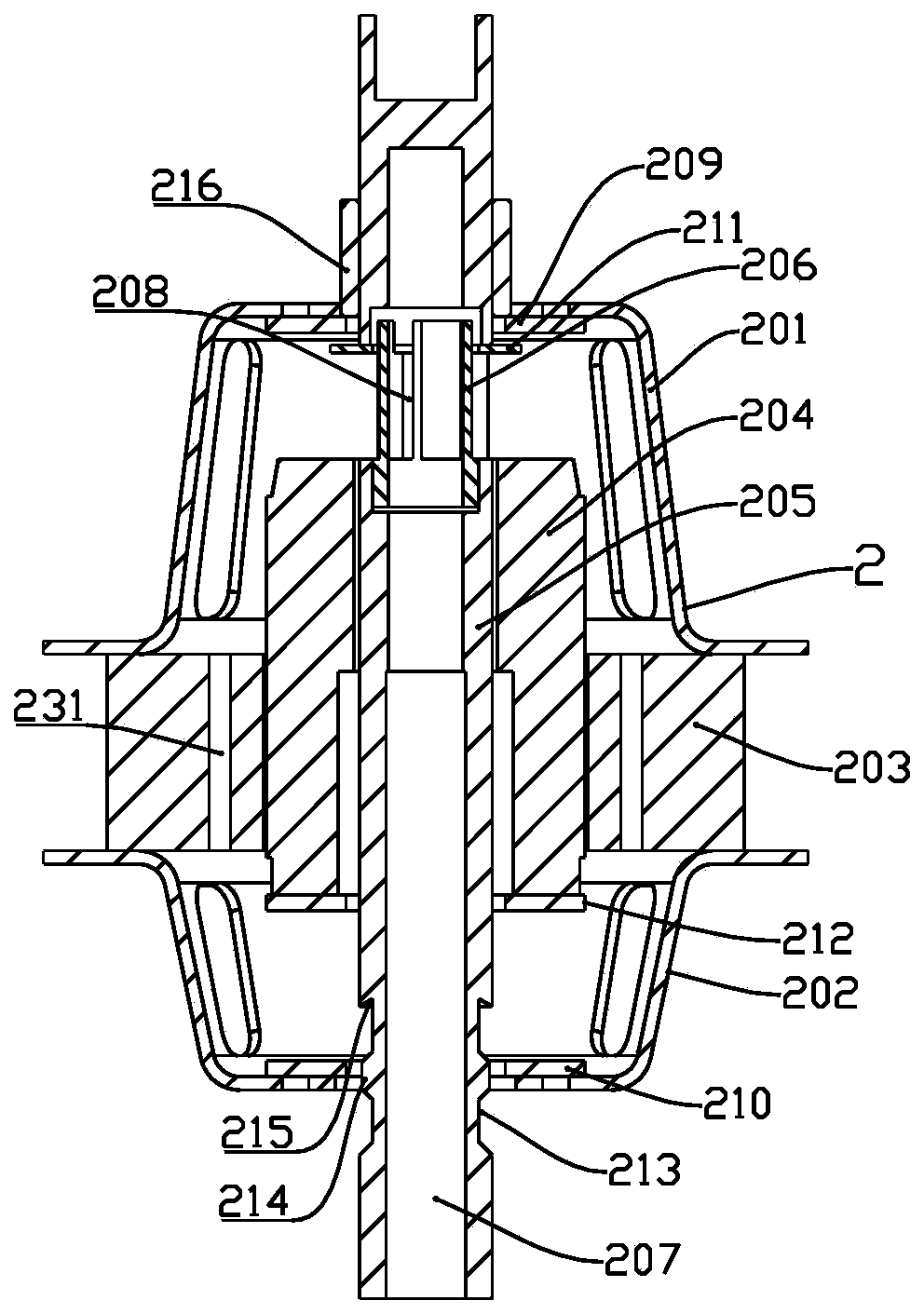

[0071] In this embodiment, an annular boss 214 is provided on the rotating shaft 205 in the annular groove 213 , and there is a certain gap between the annular boss 214 and the valve sleeve. A ring-shaped flow equalizing ring channel is formed between the outer ring end face of the annular boss 214 and the valve sleeve. After the refrigerant enters the ring groove, it moves upward through the flow equalizing ring. The setting of the flow equalizing ring structure can ensure The uniformity of the fluid flow direction in the ring groove.

[0072] The upper part of the ring groove 213 forms a backwater bay 215 with a triangular annular cross-section on the rotating shaft, and the backwater bay forms a cavity structure on the rotating shaft that opens toward the direction of the ring groove. A downwardly inclined inner chamfer structure is formed. When the liquid in the ring groove 213 is continuously flowing upwards, it interacts with the backwater bay of the ring groove, so tha...

Embodiment 3

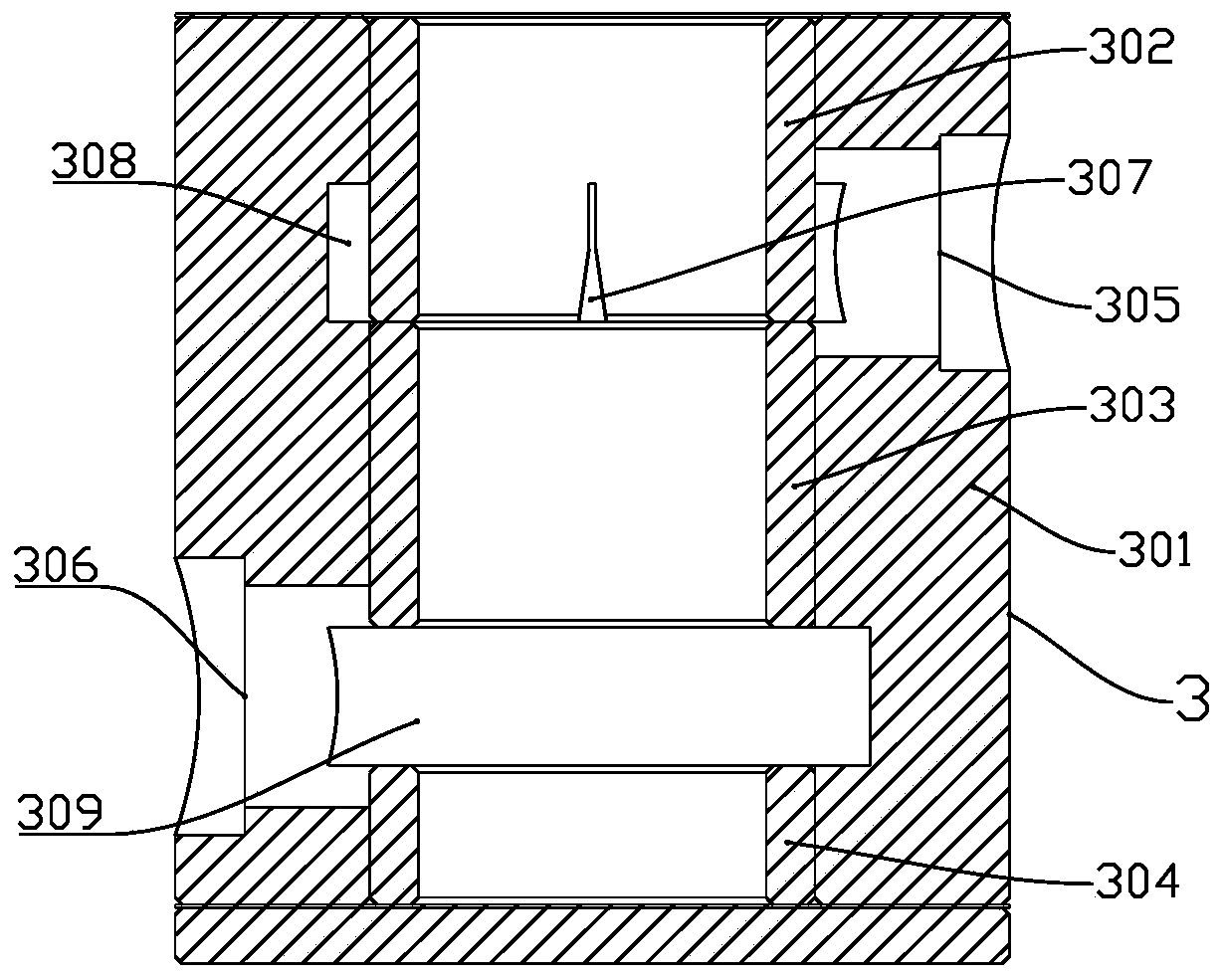

[0074] In this embodiment, a horizontal first annular groove 308 is provided in the valve body 301 on the plane where the liquid supply port is located, and the first annular groove 308 communicates with the liquid supply port 305 . The first annular groove is used to communicate with the liquid supply port and the throttle opening. At the same time, the annular structure of the first annular groove can transition and buffer the high-pressure fluid entering through the liquid supply port, so as to reduce the pressure and impact of the high-pressure liquid on the rotation of the shaft. influences. A horizontal second annular groove 309 is provided in the valve body 301 on the plane where the pump liquid port is located, and the second annular groove 309 communicates with the pump liquid port 306 and the interior of the valve sleeve respectively. By providing the second annular groove, the annular structure of the second annular groove also plays the role of transitioning and bu...

Embodiment 4

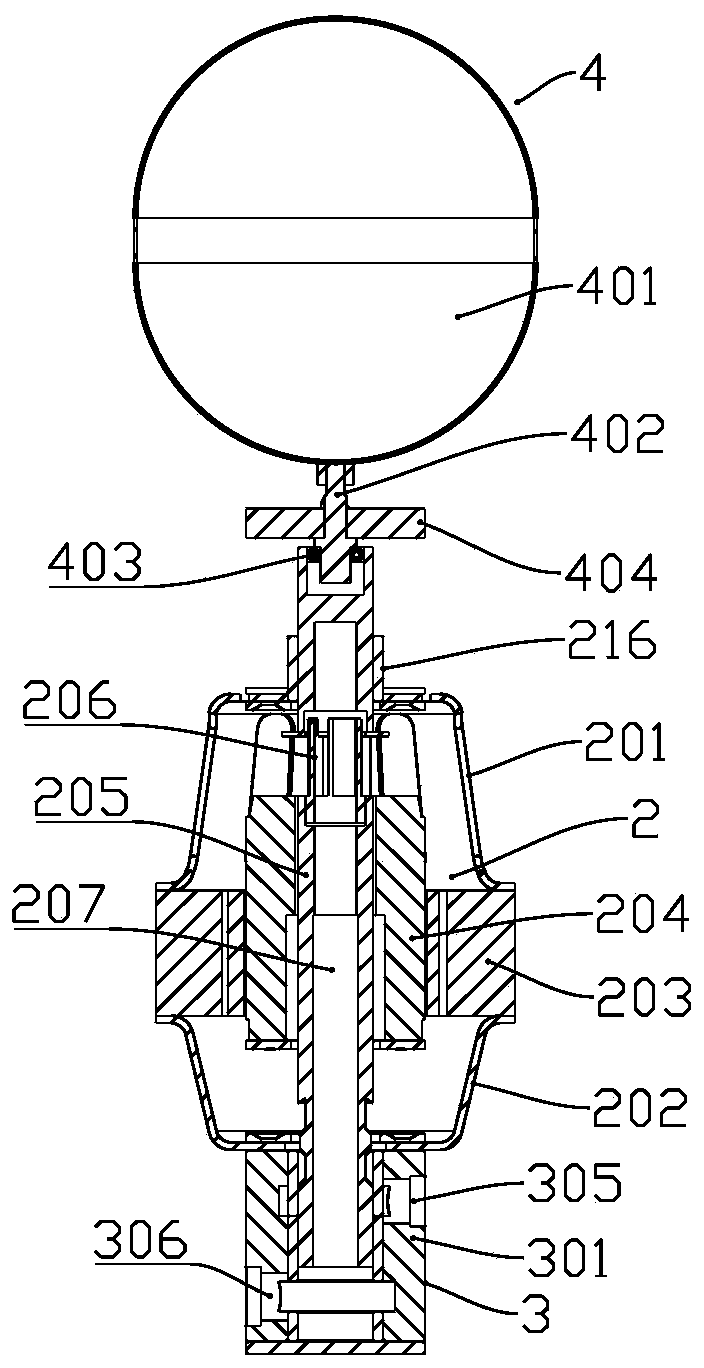

[0078] Such as Figure 5 , in the flooded evaporating device of the present invention, the valve body 301 of the self-balancing pump liquid device is arranged outside the tank body 101, the upper end of the valve body 301 is fixedly connected to the tank body 101, and the bottom of the tank body 101 and the upper end surface of the valve body 301 Sealed connection between.

[0079] Specifically, an opening is provided at the bottom of the tank body 101, and the valve body 301 is arranged below the opening of the tank body 101. The valve body 301 is tightly fitted and connected between the opening end of the valve cavity and the tank body 101, so that the valve cavity and the tank body communicated to form a sealed cavity.

[0080] The working process of the device will be described in conjunction with the structure and working principle of the flooded evaporation device in this embodiment. The precise control of the cooling liquid supply by the device is realized through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com