Method for improving resolution of laser ultrasonic visual image

An image resolution, laser ultrasound technology, applied in image analysis, image enhancement, analysis of solids using sonic/ultrasonic/infrasonic waves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

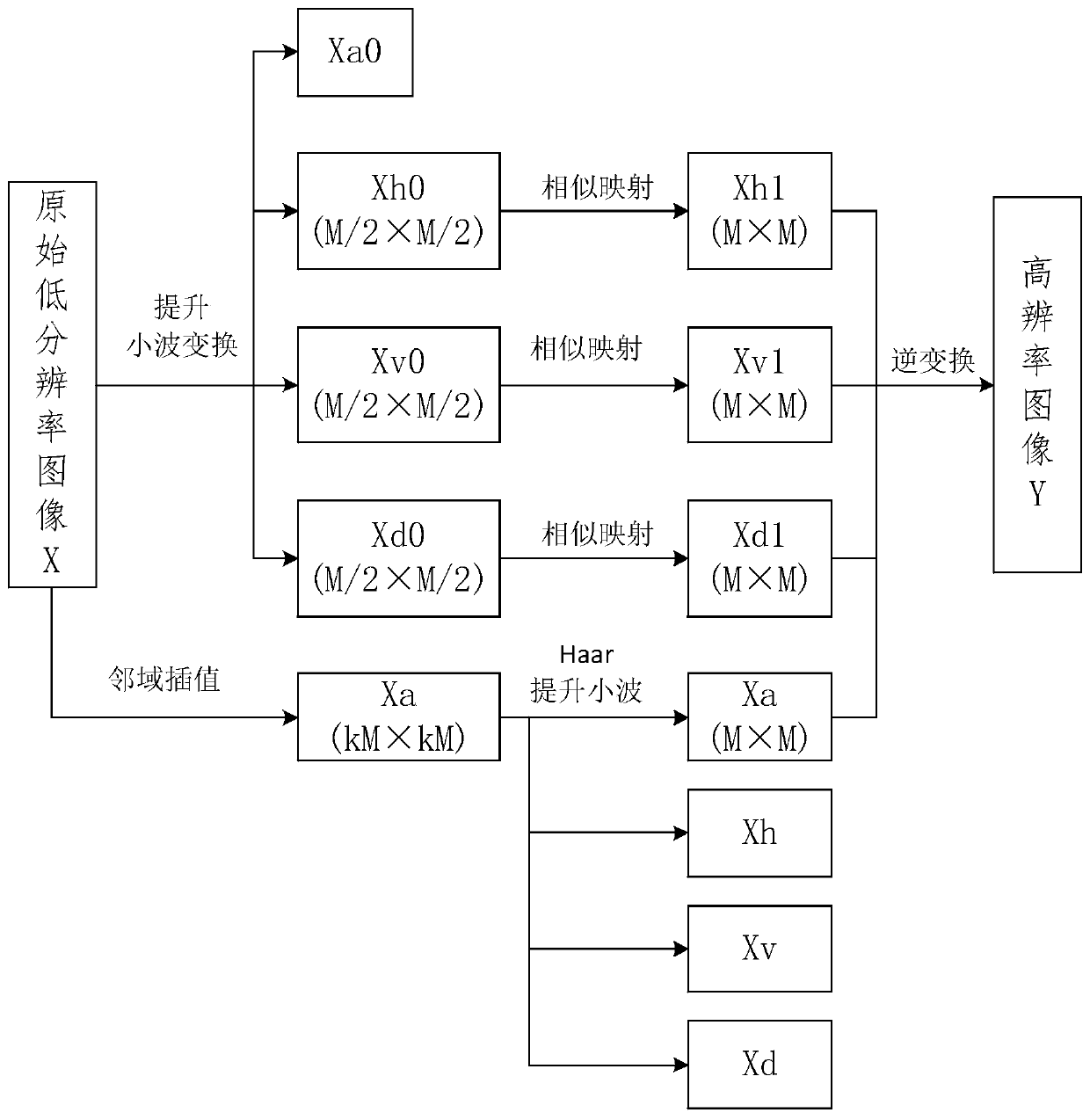

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0027] The laser ultrasonic non-destructive testing system uses a Q-switched Nd:YAG pulsed laser (pulse width 10ns, repetition rate up to 1000Hz, pulse energy up to 10mJ) to excite the laser, and controls the laser point to scan on the workpiece through the deflection mirror. Type acoustic emission sensor (resonance frequency 500-2000KHz, size Φ6mm) receives ultrasonic signals, after amplification and filtering (amplifier gain 60dB), synchronous trigger signal acquisition card (sampling frequency 16.66MHz, sampling depth 2000 points) collects data and stores them in the computer. Image display with ultrasound propagation visualization software.

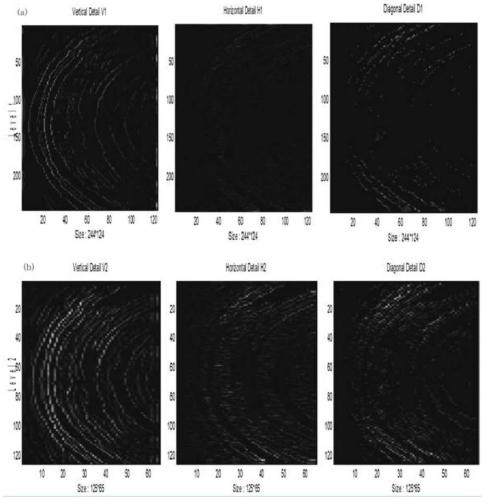

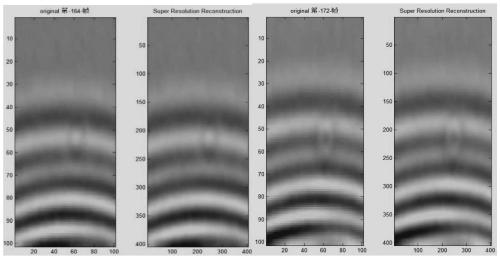

[0028] The above-mentioned system is used to carry out detection experiments on large-diameter pipe wall welds. The size of the laser ultrasonic detection area is 47mm×94mm. The laser point is contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com