Radiant wall burner

一种燃烧器、燃烧器砖的技术,应用在燃烧器、气体燃料燃烧器、燃烧类型等方向,能够解决逆燃风险可能大、降低设备性能、修理或更换的成本巨大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present disclosure can be more easily understood by referring to the following description. Additionally, numerous specific details are set forth in order to provide a thorough understanding of the embodiments described herein. However, it will be understood by those of ordinary skill in the art that the embodiments described herein may be practiced without these specific details. In other instances, methods, procedures and components have not been described in detail so as not to obscure the related features being described. Additionally, this description should not be considered as limiting the scope of the embodiments described herein.

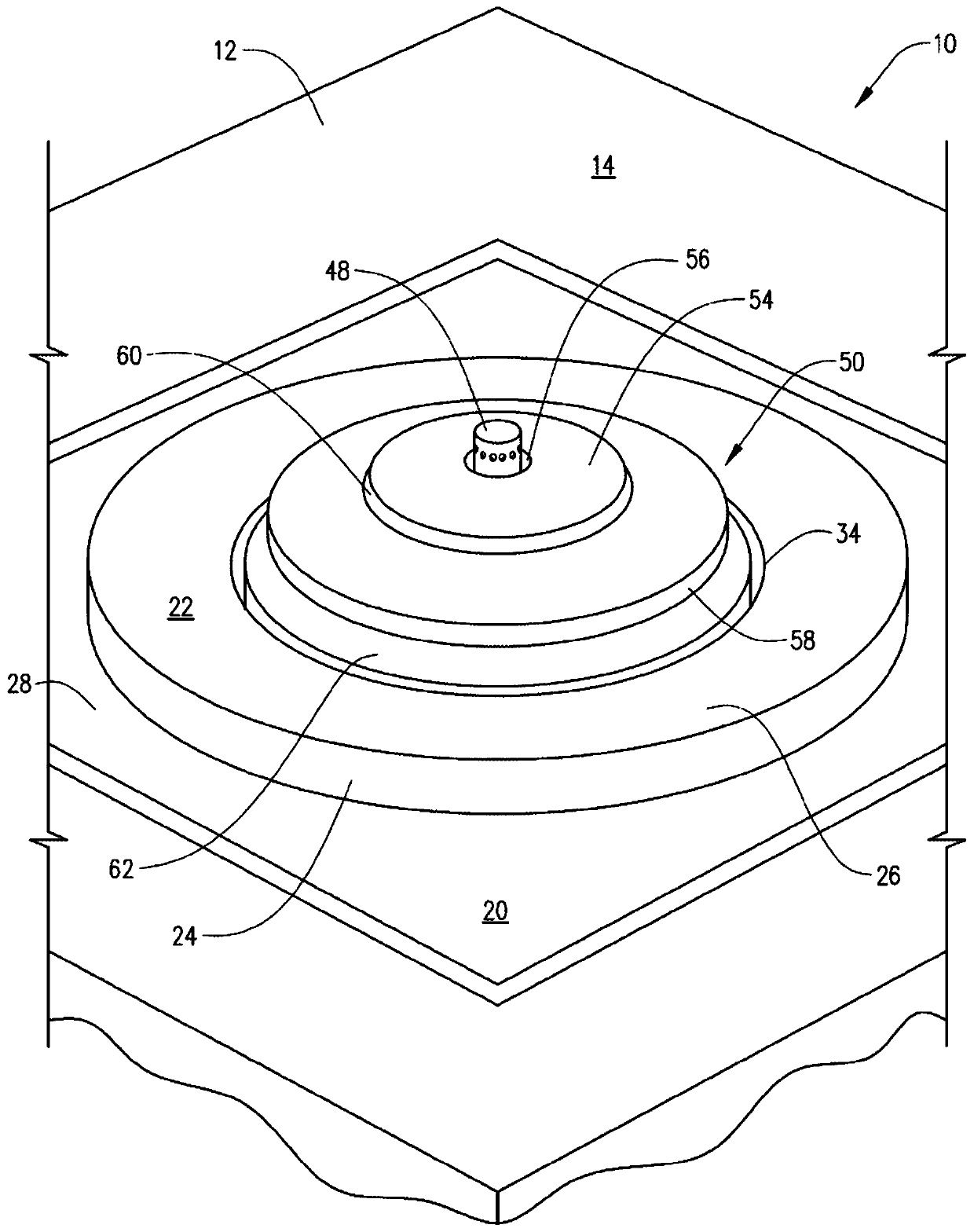

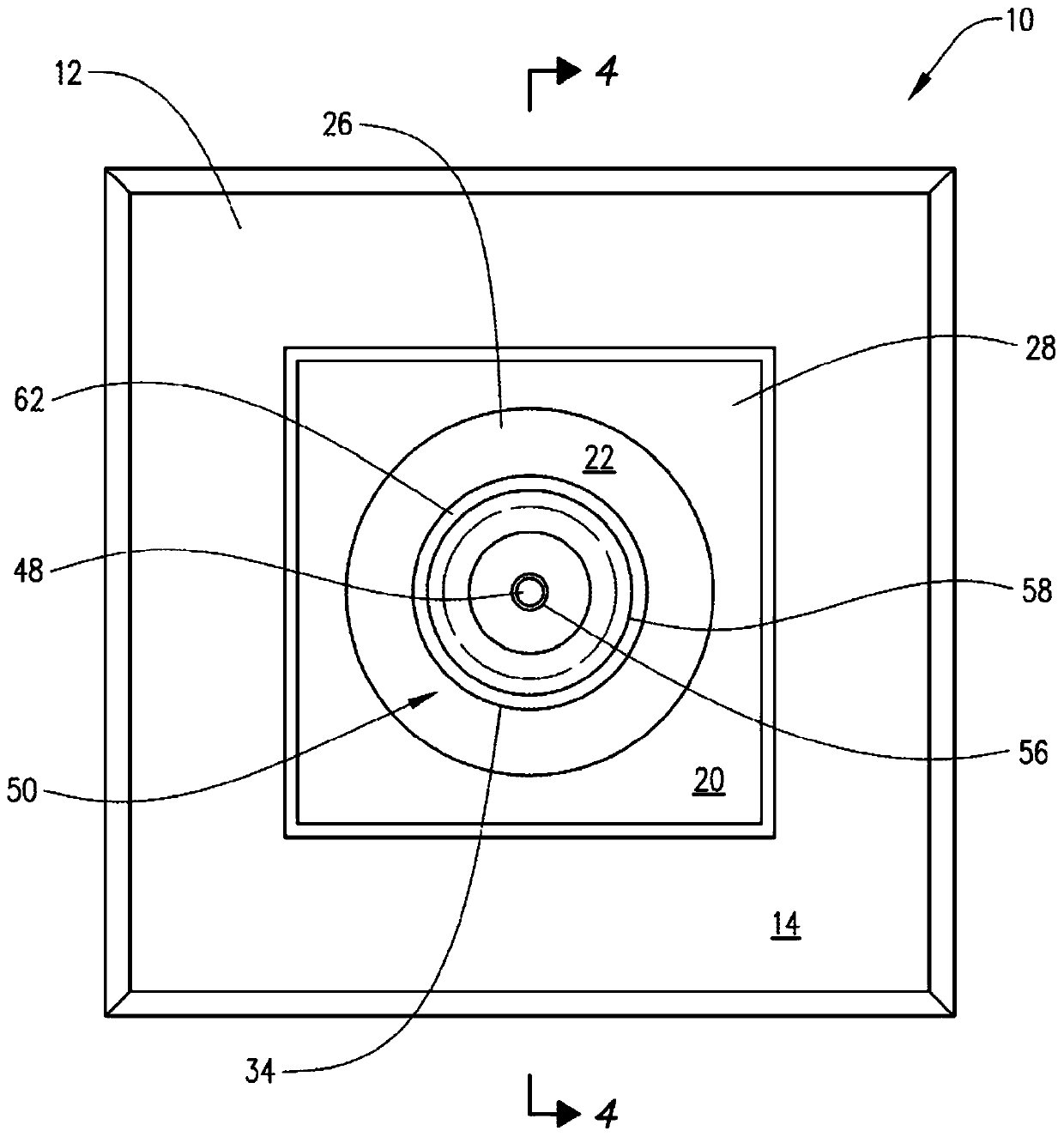

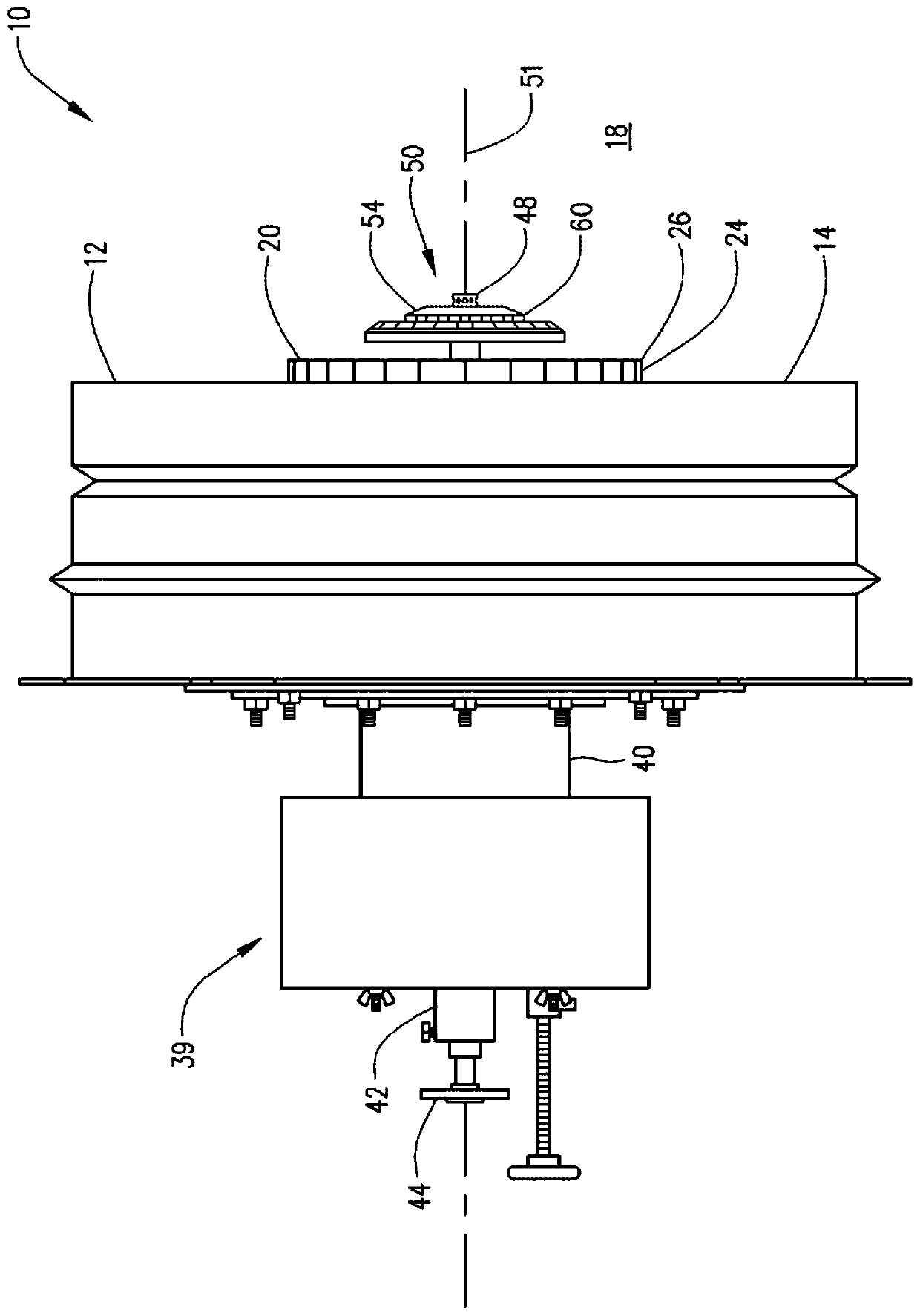

[0034] The features of the present combustor and methods related thereto will be described with reference to the drawings, wherein like reference numerals are used herein to refer to like elements throughout the various views, different embodiments are shown and described. The drawings are not necessarily to scale, and in some ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com