Method for preparing frozen dough by ultrasonic and magnetic field combination

A technology for frozen dough and ultrasonic waves, which is applied in the fields of food ultrasonic treatment, food freezing, food science, etc., can solve the problems of texture change, sensory quality reduction, energy waste, etc., achieve good practical application value, improve fermentation capacity, reduce damage. ring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

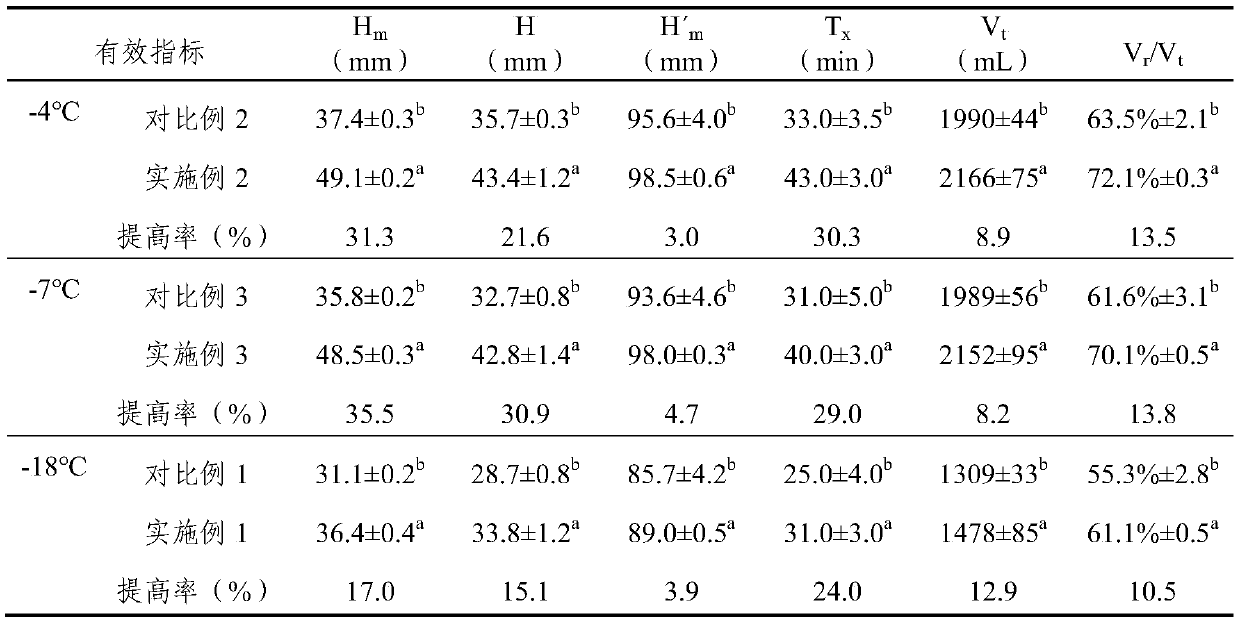

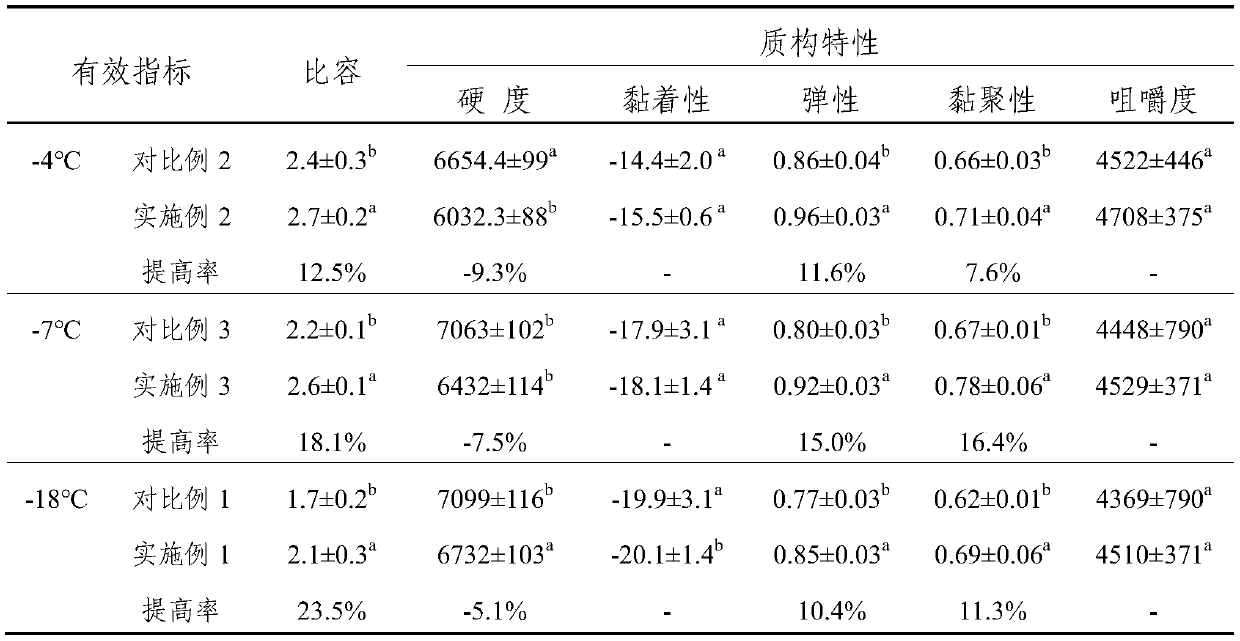

Embodiment 1

[0026] (1) Put flour (100 parts), dry yeast (2 parts), salt (2 parts) and water (50 parts) in a vertical dough mixer and knead for 10 minutes to form a dough, then seal it with plastic wrap;

[0027] (2) Put the dough prepared in step (1) into a ziplock bag, and place it in an ultrasonic working pool with an initial temperature of 4°C for ultrasonic treatment for 6 minutes. The working mode of the ultrasonic is that the probe-type ultrasonic and the flat-plate ultrasonic work synchronously, and the total power density is 105W / L. The frequency of the probe type ultrasonic wave is 20kHz, the ultrasonic working time is 5s, the intermittent time is 5s, the frequency of the flat type ultrasonic wave is 60kHz, and it works continuously;

[0028] (3) Put the dough after the ultrasonic treatment in step (2) into a refrigerator with a built-in constant magnetic field for freezing treatment. The strength of the magnetic field was 100Gs, the freezing temperature was -18°C, and the freez...

Embodiment 2

[0030] Example 2 The same method as Example 1 was used to prepare steamed buns, the only difference being that the temperature of the freezing treatment in step (3) of Example 2 was -4°C, and the freezing time was 4 days.

Embodiment 3

[0032] In Example 3, steamed buns were prepared in the same way as in Example 1, except that the freezing temperature in step (3) of Example 3 was -7°C, and the freezing time was 7 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com