Clean production method for high saline diluting fermented soy sauce

A high-salt dilute state fermentation and production method technology, applied in the field of fermentation, can solve the problems of insufficient cleaning of fermentation tanks, and achieve the effect of sufficient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

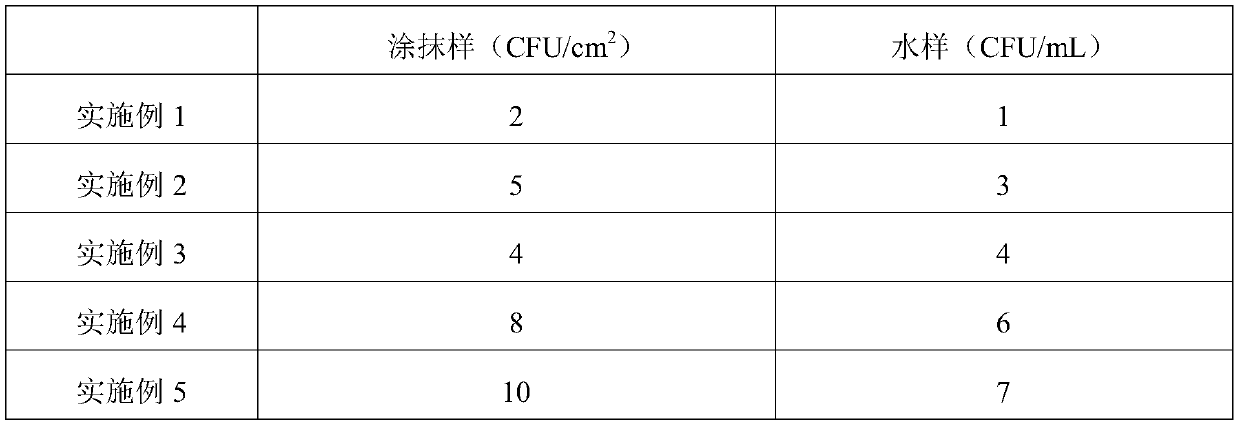

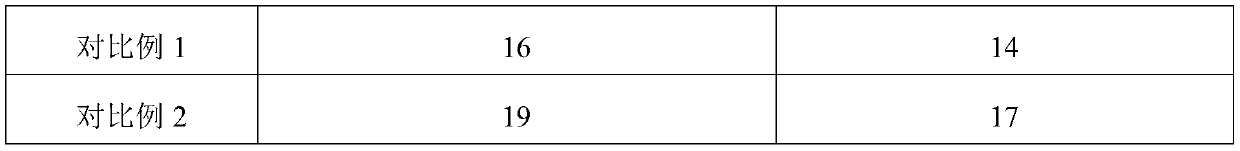

Examples

Embodiment 1

[0029] 1) Strain screening: Aspergillus oryzae with a neutral protease activity of 3600U / g dry basis was screened out by the Folin method.

[0030] 2) Koji making: the soybean meal is processed and cooked at a pressure of 0.05 MPa, a temperature of 115° C., and a holding time of 10 minutes. The wheat is fried at a pressure of 0.01MPa, a temperature of 300°C, and a moisture content of 0.5%. After mixing at a ratio of 1:1, the improved Aspergillus oryzae was inserted, and koji was made at 28°C.

[0031] 3) Fermentation: mix the prepared koji with 15% salt water, and ferment at 140m 3 The fermenter is closed for fermentation. The fermentation temperature of each stage is controlled by the constant temperature system of the fermenter. The early fermentation temperature is 8°C, and the fermentation time is 1.5 months; the middle fermentation temperature is 20°C, and the fermentation time is 3 months; the late fermentation temperature is 30°C, and the fermentation time is 2 months...

Embodiment 2

[0035] 1) Strain screening: Aspergillus oryzae with a neutral protease activity of 3600U / g dry basis was screened out by the Folin method.

[0036] 2) Koji making: the soybean meal is processed and cooked at a pressure of 0.05 MPa, a temperature of 115° C., and a holding time of 10 minutes. The wheat is fried at a pressure of 0.01MPa, a temperature of 300°C, and a moisture content of 0.5%. After mixing at a ratio of 1:1, the improved Aspergillus oryzae was inserted, and koji was made at 28°C.

[0037] 3) Fermentation: mix the prepared koji with 15% salt water, and ferment at 140m 3 The fermenter is closed for fermentation. The fermentation temperature of each stage is controlled by the constant temperature system of the fermenter. The early fermentation temperature is 8°C, and the fermentation time is 1.5 months; the mid-stage fermentation temperature is 20°C, and the fermentation time is 3 months; the late fermentation temperature is 30°C, and the fermentation time is 2 mon...

Embodiment 3

[0040] 1) Strain screening: Aspergillus oryzae with a neutral protease activity of 3600U / g dry basis was screened out by the Folin method.

[0041] 2) Koji making: the soybean meal is processed and cooked at a pressure of 0.05 MPa, a temperature of 115° C., and a holding time of 10 minutes. The wheat is fried at a pressure of 0.01MPa, a temperature of 300°C, and a moisture content of 0.5%. After mixing at a ratio of 1:1, the improved Aspergillus oryzae was inserted, and koji was made at 28°C.

[0042] 3) Fermentation: mix the prepared koji with 15% salt water, and ferment at 140m 3 The fermenter is closed for fermentation. The fermentation temperature of each stage is controlled by the constant temperature system of the fermenter. The early fermentation temperature is 8°C, and the fermentation time is 1.5 months; the mid-stage fermentation temperature is 20°C, and the fermentation time is 3 months; the late fermentation temperature is 30°C, and the fermentation time is 2 mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com