A sewage dispersion pretreatment device

A pretreatment device and sewage technology, applied in the direction of separation methods, filtration separation, chemical instruments and methods, etc., can solve problems such as easy blockage of filter holes, limited range of action of the filter mechanism, and influence on the filtering effect, so as to reduce friction, Effect of increasing impact force and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

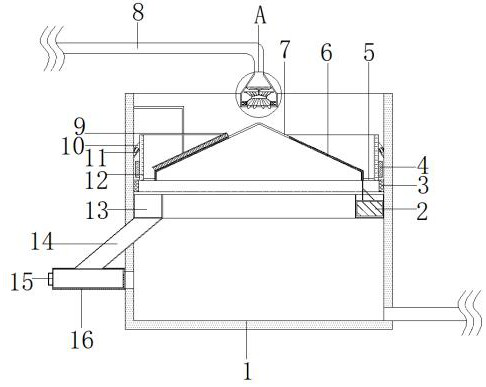

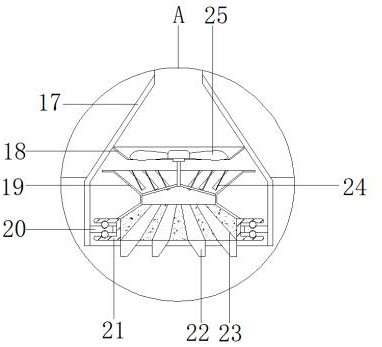

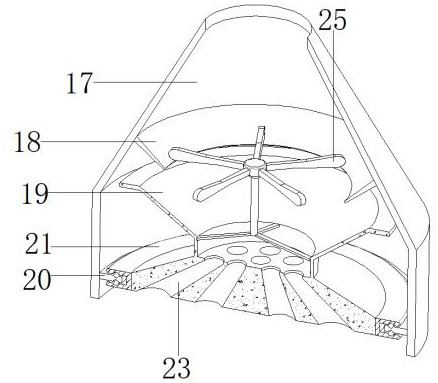

[0031] refer to Figure 1-5 , a sewage dispersion pretreatment device, comprising a sewage input pipe 8 welded with a water separation cylinder 17 at the end and a treatment box 1, the inside of the water separation cylinder 17 is equipped with a water separation mechanism, and the inner wall of the treatment box 1 is equipped with a self-cleaning Filtration mechanism, the water distribution mechanism includes a fixed ring plate 20 welded to the inner bottom of the water distribution cylinder 17 and a conical disc 18 welded to the inner top of the water distribution cylinder 17, and the inside of the water distribution cylinder 17 is provided with a water receiving end 19, and the water receiving end 19 The inner wall of the top end is welded with spiral blades 24 distributed in an equidistant ring, and the bottom end of the water receiving end 19 is provided with symmetrically distributed oblique spiral water channels 23, and the bottom ends of the oblique spiral water channel...

Embodiment 2

[0042] refer to Figure 6 , a sewage dispersion pretreatment device, compared with Embodiment 1, this embodiment also includes that the spiral blades 24 are all provided with arc-shaped grooves 27 .

[0043] When the present invention is in use, the spiral blade 24 is provided with an arc-shaped groove 27 to increase the contact area between the spiral blade 24 and the sewage, and increase the impact force generated by the sewage on the spiral blade 24, so as to ensure the smooth rotation of the water receiving end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com