Vermiculite-based ion screening film and preparation method thereof

A technology of ion sieve and vermiculite, applied in the direction of chemical instruments and methods, membrane, membrane technology, etc., can solve the problems such as limiting the increase of added value, and achieve the effect of simple preparation method, wide applicability, efficient and rapid selective screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Mix 0.3g of expanded vermiculite with 100mL of saturated NaCl solution, put it in a high-temperature oven, set the temperature of the oven at 110°C, and heat for 2 hours. After heating, repeat suction filtration with 100mL of deionized water Washing 3 times, 100mL absolute ethanol suction filtration and washing 1 time to obtain powder A;

[0033] Step 2: Mix powder A with 100mL, 2mol / L LiCl solution, put it in a high-temperature oven, set the temperature of the oven at 110°C, and heat for 2 hours. After heating, repeat suction filtration and washing with 100mL deionized water 3 times, 100mL absolute ethanol suction filtration and washing once to obtain powder B;

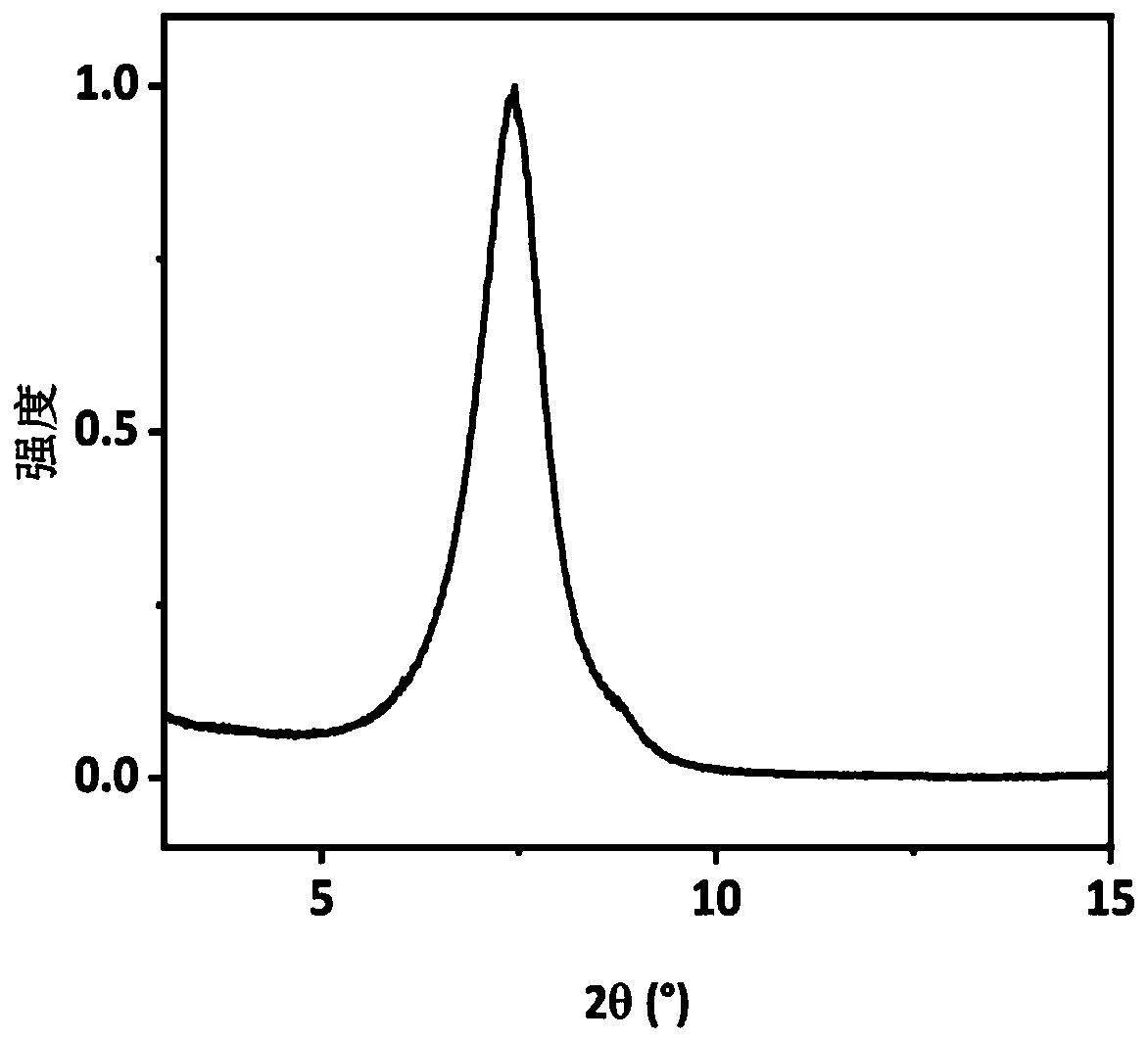

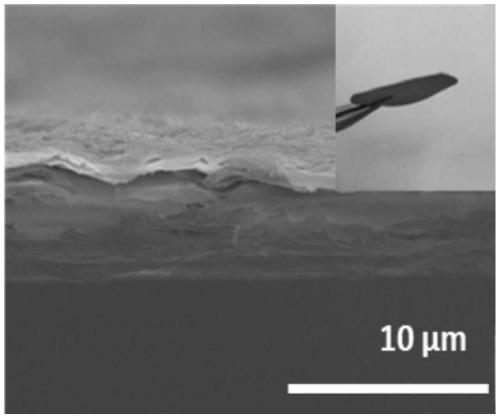

[0034] Step 3: After mixing the powder B with 80 mL of deionized water, it was stirred and stripped by a high-shear dispersion emulsion homogenizer at a rotation speed of 20,000 rpm, and the stirring and stripping time was 10 minutes to obtain a suspension A;

[0035] Step 4: Remove unstripped vermicu...

Embodiment 2

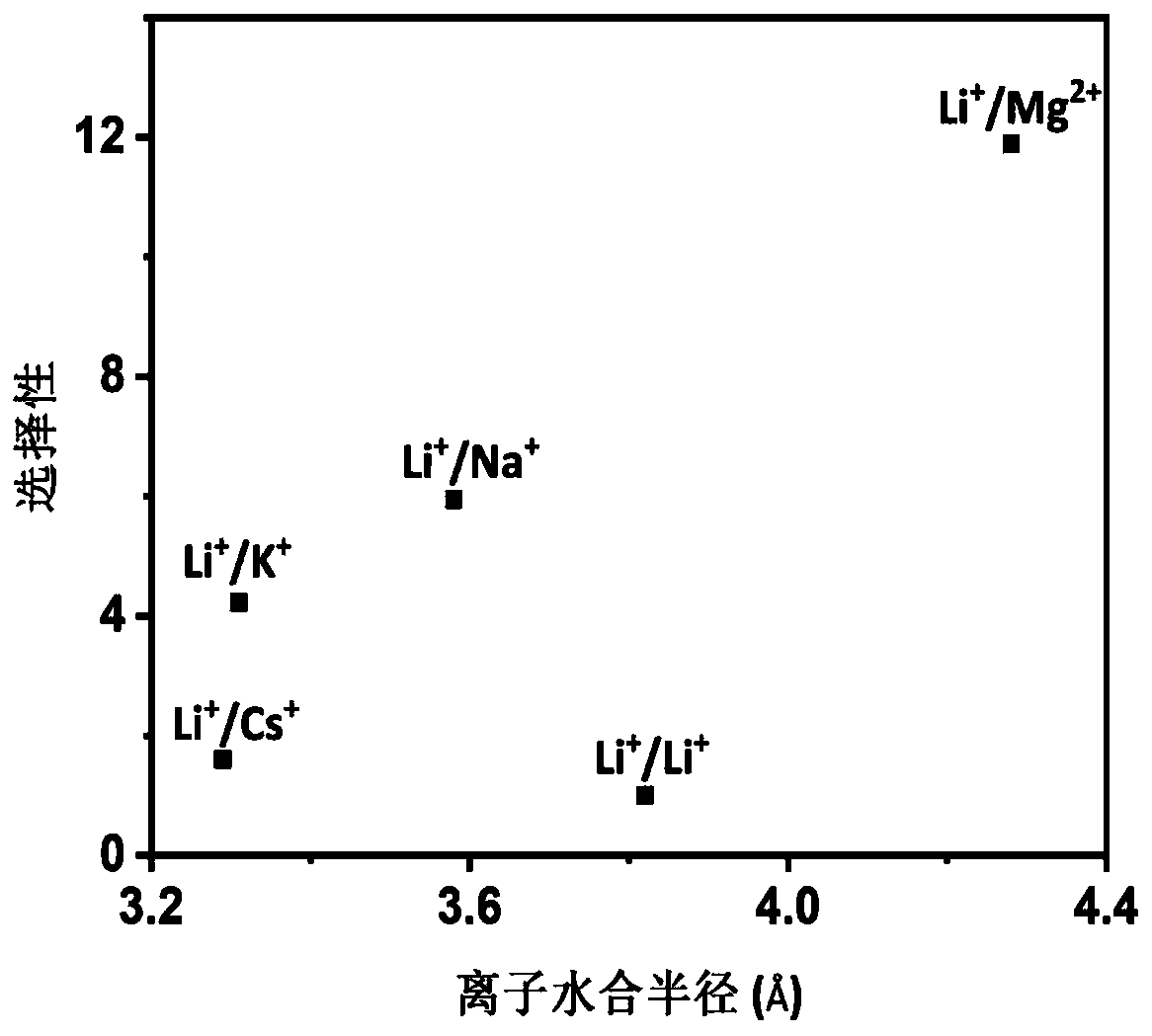

[0044] The difference between this example and Example 1 is that the volume of saturated NaCl solution mixed with expanded vermiculite in step 1 of this example is 70 mL, and the volume of LiCl solution mixed with powder A in step 2 is 70 mL. The concentration of the vermiculite nanosheet dispersion in the range of 1000-2000 rpm obtained by gradient centrifugation decreased slightly to 5.52 mg / mL. Through experimental measurement, the vermiculite-based ion sieving membrane prepared in the present embodiment has a great influence on Li + 、Na + 、K + 、Cs + , Mg 2+ The permeation rates are 0.453, 0.073, 0.109, 0.287, 0.0384mol h -1 m -2 , basically consistent with Example 1.

Embodiment 3

[0046] The difference between this embodiment and Embodiment 1 is that the oven heating time in steps 1 and 2 of this embodiment is 4 hours. The concentration of the vermiculite nanosheet dispersion in the range of 1000-2000 rpm obtained by gradient centrifugation increased slightly to 6.03 mg / mL. Through experimental measurement, the vermiculite-based ion sieving membrane prepared in the present embodiment has a great influence on Li + 、Na + 、K + 、Cs + , Mg 2+ The permeation rates are 0.470, 0.080, 0.112, 0.293, 0.0404mol h -1 m -2 , basically consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com