Special device for mixing fracturing fluid

A special device and fracturing fluid technology, applied in the direction of mixer, transportation and packaging, mixer accessories, etc., can solve the problems of "powder in water, uneven mixing of liquid configuration, etc., to achieve increased hydration viscosity, convenient cleaning, and quality assurance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

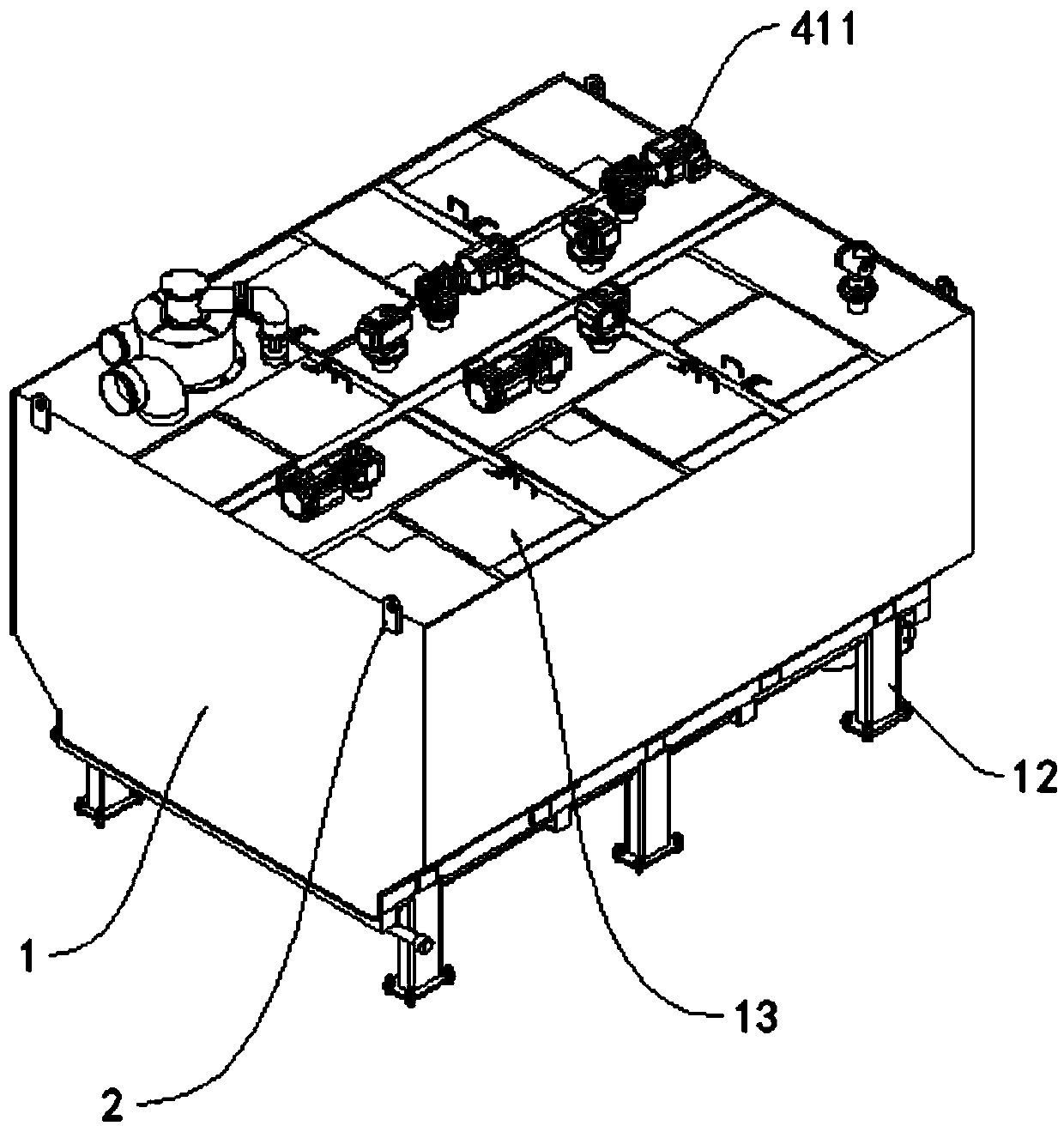

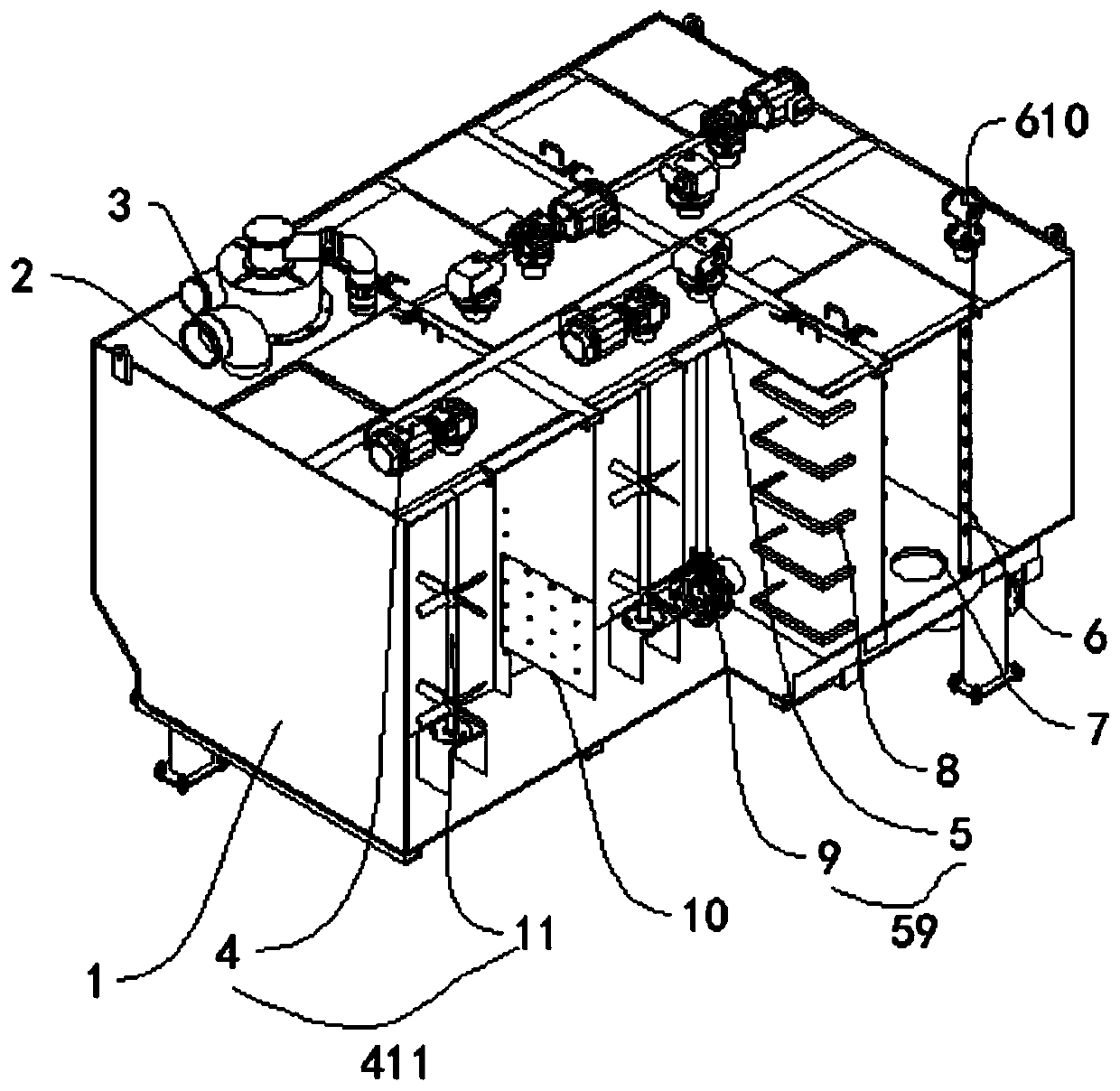

[0041] The special device for fracturing fluid mixing provided by the embodiment 1 of the present invention includes a mixing tank, a diffuser, a liquid outlet pipe, a liquid level adjustment structure, and a stirring structure. The mixing tank is provided with a first-in-first-out restriction liquid The diffuser is installed on the mixing tank body, the diffuser is connected with the inside of the mixing tank body, the liquid level adjustment structure and the stirring structure are both installed inside the mixing tank body, The liquid outlet pipe communicates with the bottom of the mixing tank.

[0042] The working principle of this embodiment is as follows: because the traditional liquid configuration is extremely easy to cause uneven mixing, the phenomenon of "powder in water" occurs, which seriously affects the work progress. In the present invention, the traditional fracturing fluid mixing form is changed, and the S-shaped liquid flow channel design of this scheme is used ...

Embodiment 2

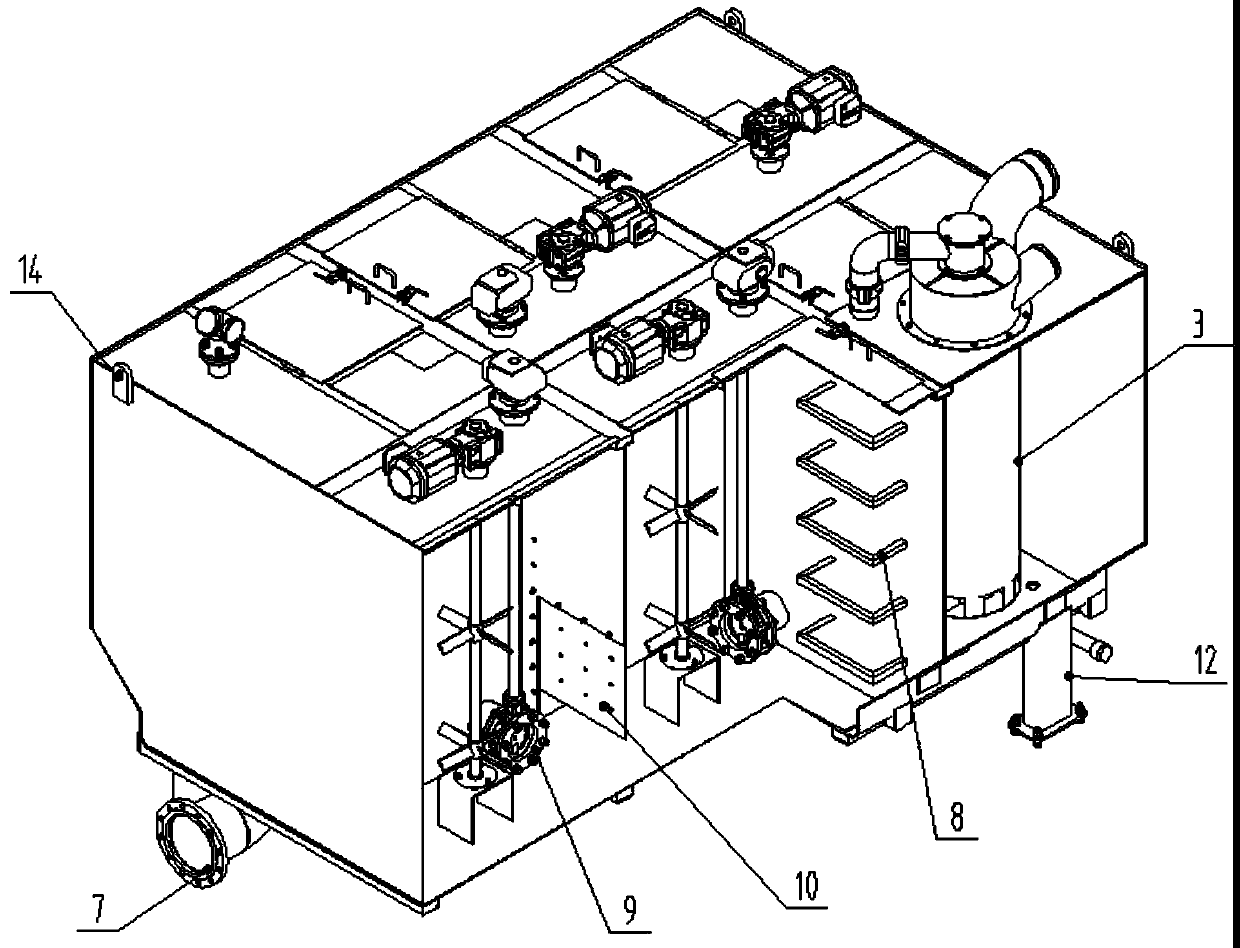

[0044] The preferred embodiment 2 of the present invention provides a special device for mixing fracturing fluid, which includes a mixing tank, a diffuser, a liquid outlet pipe, a liquid level adjustment structure, and a stirring structure. The first-out S-shaped liquid flow channel, the diffuser is installed on the mixing tank, the diffuser is connected with the inside of the mixing tank, and the liquid level adjustment structure and the stirring structure are both installed inside the mixing tank, The liquid outlet pipe is communicated with the bottom of the mixing tank. The stirring structure includes a stirrer and a stirring motor, the stirrer is installed in the S-shaped liquid flow channel, and the stirrer is connected to the output end of the stirring motor. The liquid level adjustment structure includes a liquid level gauge and a liquid level adjustment plate, the liquid level gauge is installed inside the mixing tank, and the liquid level adjustment plate can be raised...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com