Food starch processing device

A starch processing and food technology, which is applied in food ingredients, food extraction, food mechanical processing, etc., can solve the problems of lack of fluidity of starch, hindering sweet potato cutting, and unloadable containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

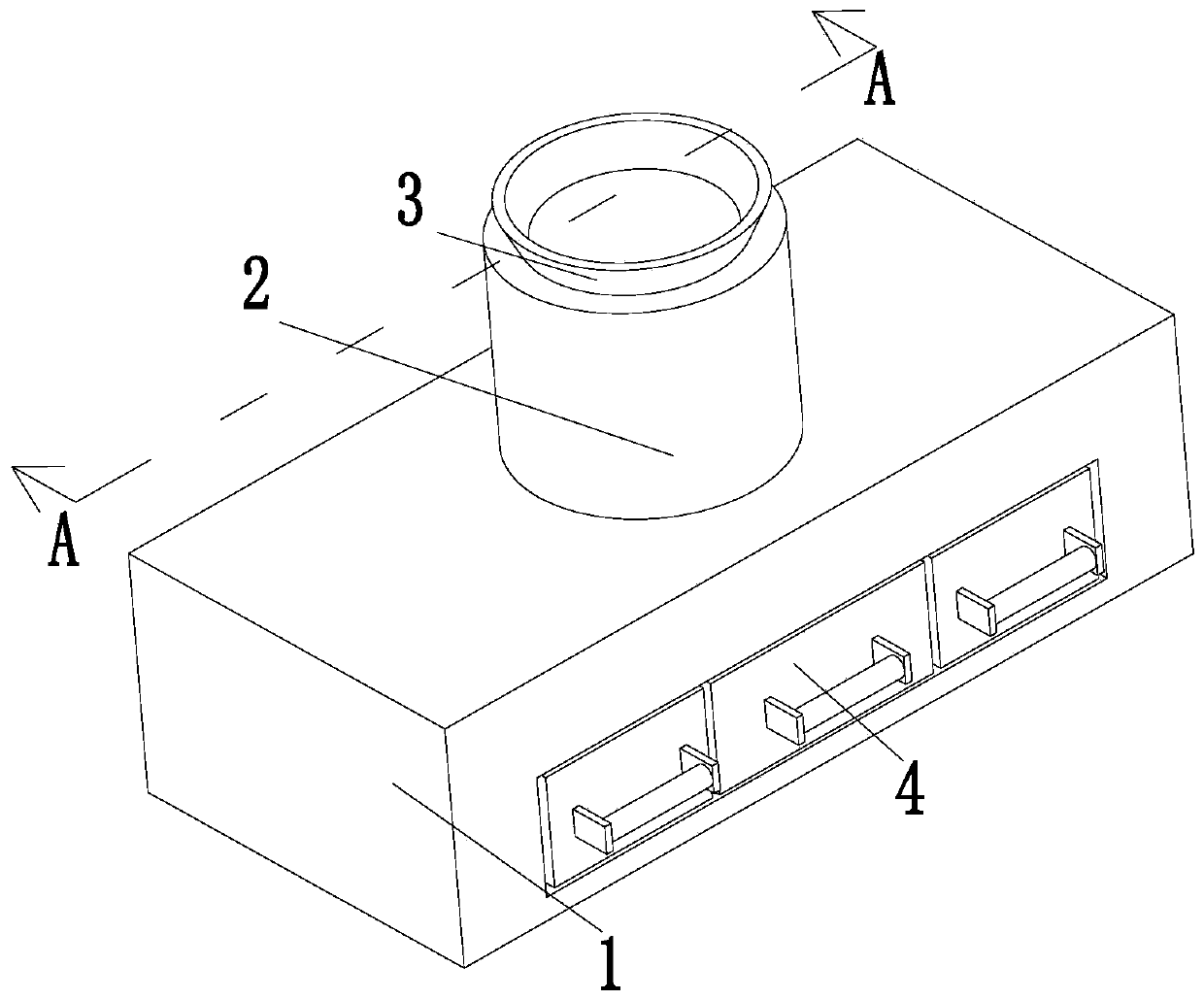

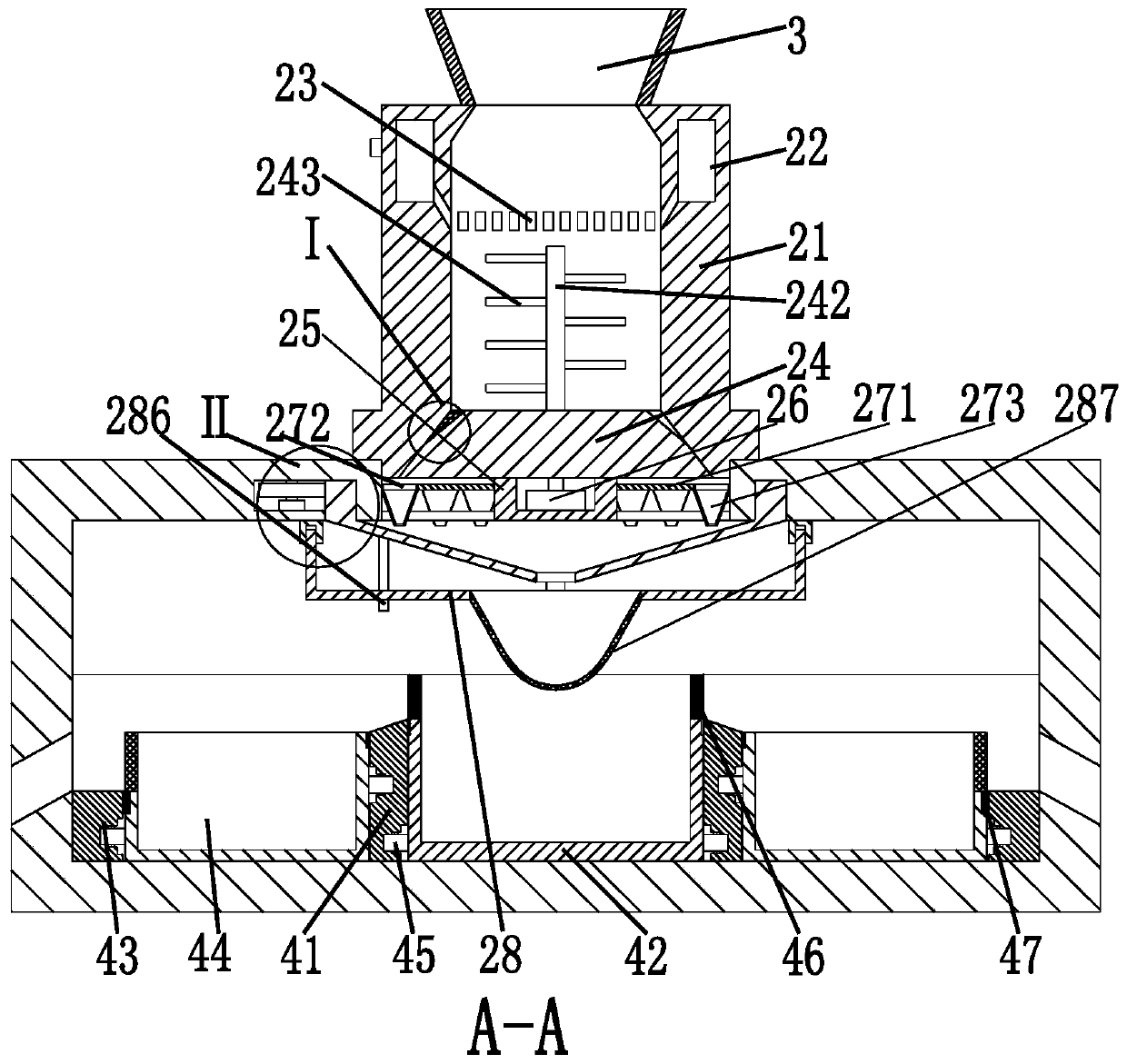

[0025] Such as Figure 1 to Figure 5 As shown, a food starch processing device includes a blanking frame 1, a crushing unit 2, a feeding port 3 and a blanking unit 4, the upper end of the blanking frame 1 is provided with a crushing unit 2, and the crushing unit 2 The upper end is provided with a feeding port 3, and the inner wall of the lower end of the feeding frame 1 is provided with a feeding unit 4; the sweet potatoes are guided from the feeding port to the crushing unit 2, and the crushing unit 2 grinds, grinds and filters the sweet potatoes, The unloading unit 4 collects and unloads the starch solution made.

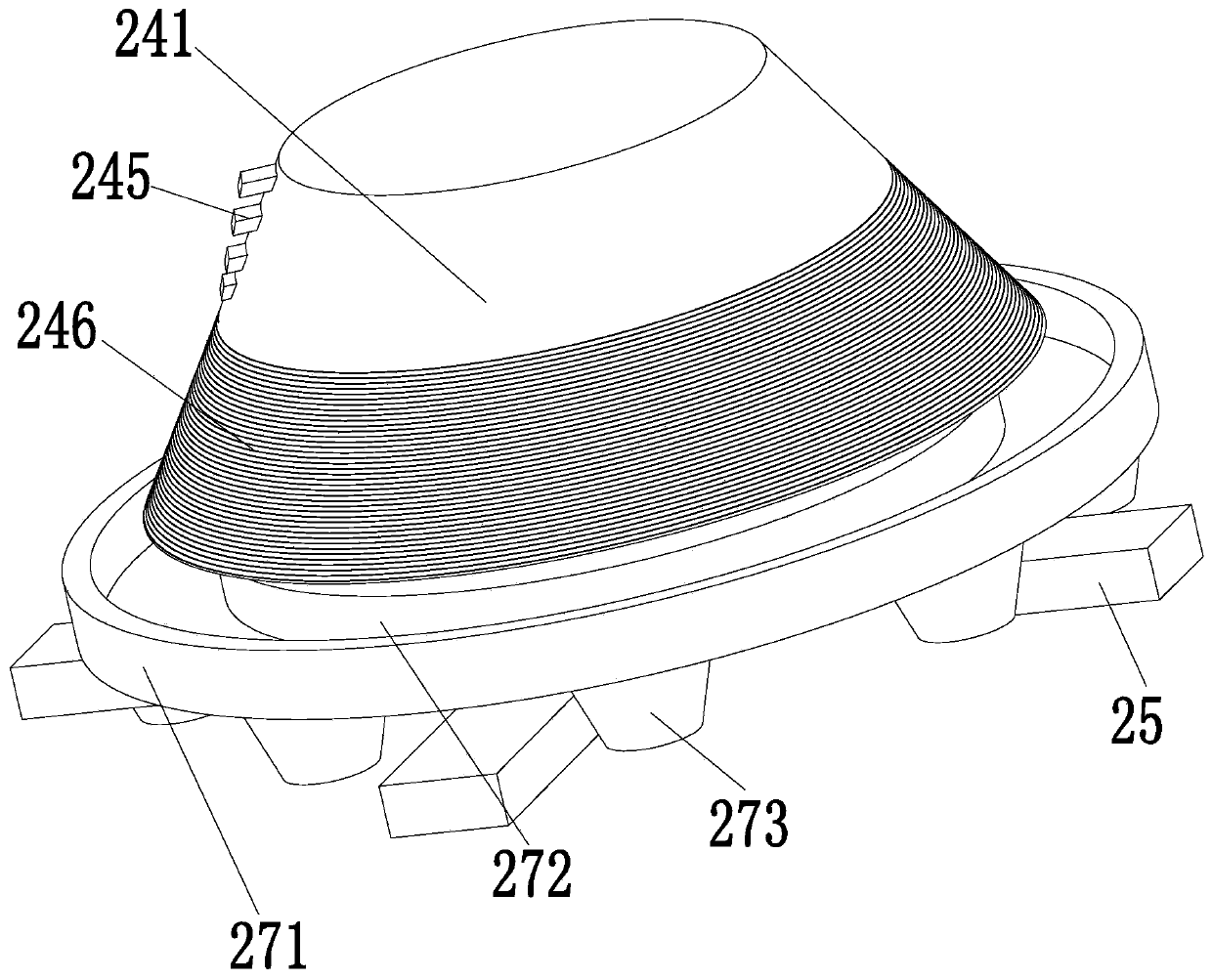

[0026] The crushing unit 2 includes a crushing cylinder 21, a water storage chamber 22, a water guide pipe 23, a crushing mechanism 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com