Improved numerically controlled lathe

An improved technology for CNC lathes, applied in the field of CNC lathes, can solve the problems of reducing the quality of processed parts, deformation of opening and closing doors, interference, etc., and achieve the effect of protecting the sealing effect, avoiding deformation, and facilitating reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

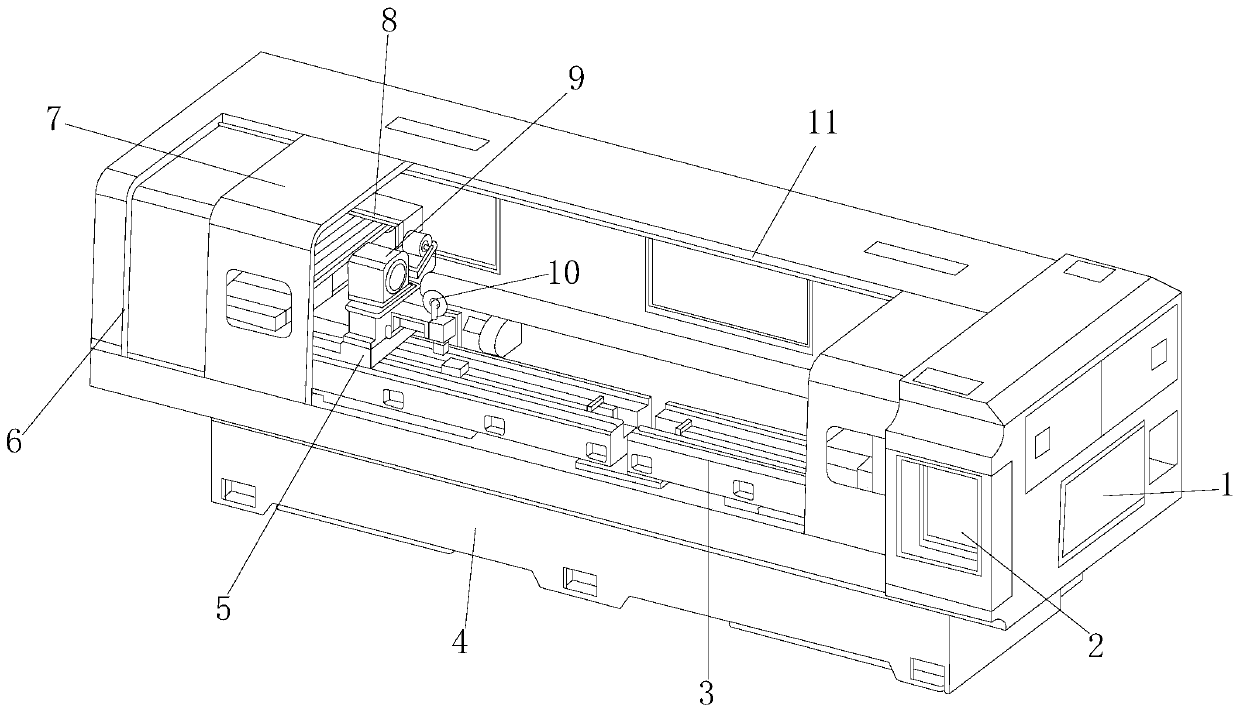

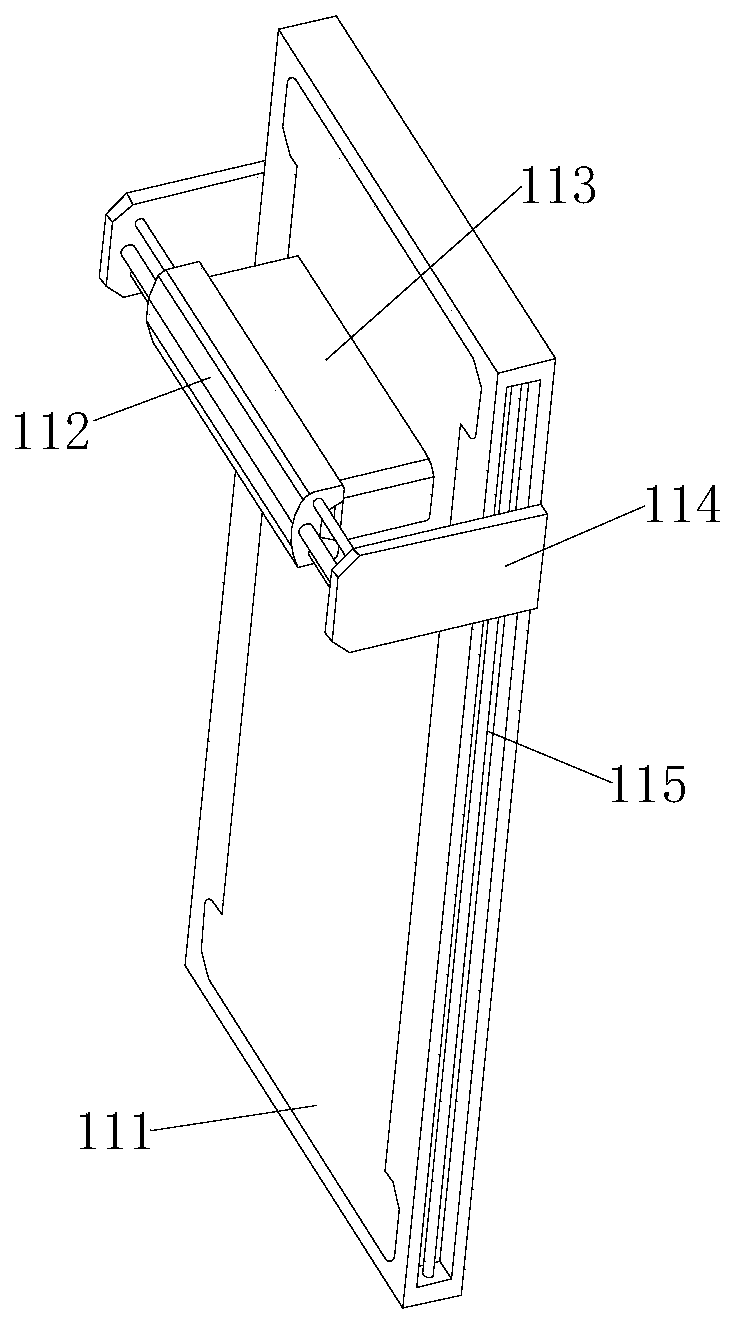

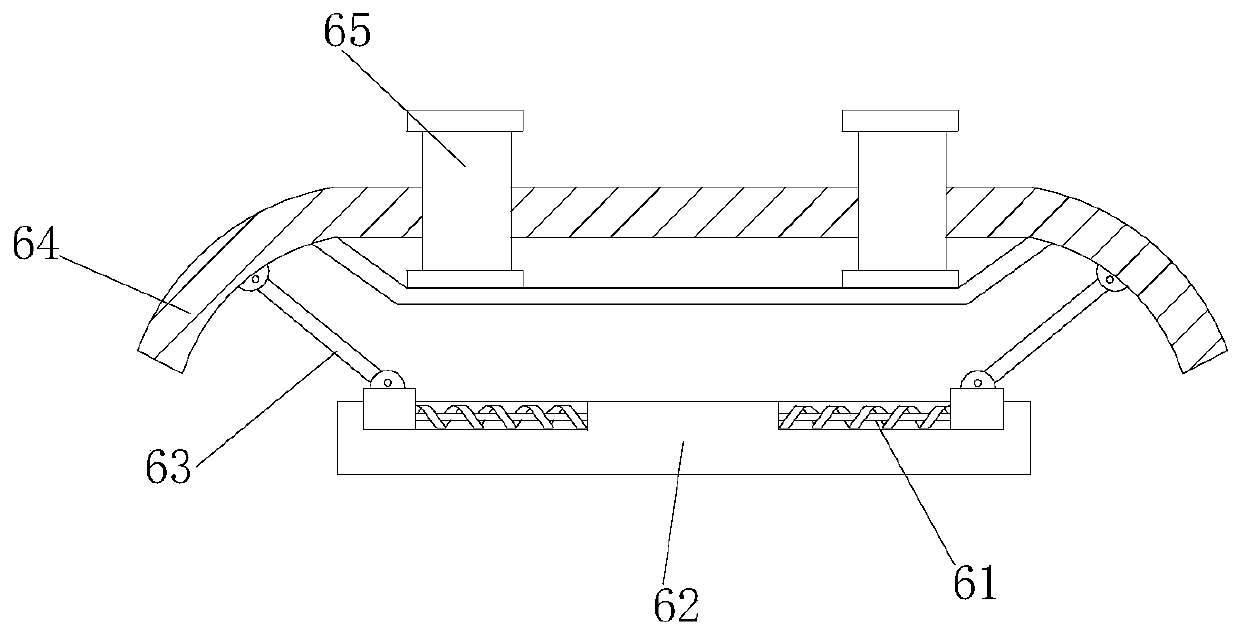

[0032] see figure 1 , the present invention provides a technical solution for an improved numerical control lathe: an improved numerical control lathe, the structure of which includes an adsorption plate 1, a control panel 2, a slide rail 3, a car body 4, a moving slider 5, a protective device 6, a switch door 7. Fixing seat 8, blowing device 9, knife holder 10, slideway 11, the rear end of the adsorption plate 1 is closely attached to the inside of the car body 4, and the upper right end of the car body 4 is provided with a control panel 2, the The left and right sides of the front end of the car body 4 are provided with switch doors 7, and the switch doors 7 are slidably connected to the slideway 11. The slideway 11 is fixedly installed on the car body 4, and protective devices are provided on both sides of the slideway 11. 6. The protection device 6 is connected to the switch door 7 through the slideway 11, one end of the protection device 6 is fitted and connected to the ...

Embodiment 2

[0040] see figure 1 , the present invention provides a technical solution for an improved numerical control lathe: an improved numerical control lathe, the structure of which includes an adsorption plate 1, a control panel 2, a slide rail 3, a car body 4, a moving slider 5, a protective device 6, a switch door 7. Fixing seat 8, blowing device 9, knife holder 10, slideway 11, the rear end of the adsorption plate 1 is closely attached to the inside of the car body 4, and the upper right end of the car body 4 is provided with a control panel 2, the The left and right sides of the front end of the car body 4 are provided with switch doors 7, and the switch doors 7 move left and right on the slideway 11. The slideway 11 is fixedly installed on the car body 4, and the two sides of the slideway 11 are provided with A protective device 6, the protective device 6 is connected with the switch door 7 through a slideway 11, one end of the protective device 6 is fitted and connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com