Film blowing machine

A technology of film blowing machine and servo motor, which is applied in the direction of removing smoke and dust, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of time-consuming and laborious, machine idling, troublesome and troublesome cleaning, etc., to achieve high operation efficiency and ensure health and safety. , Easy to clean up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

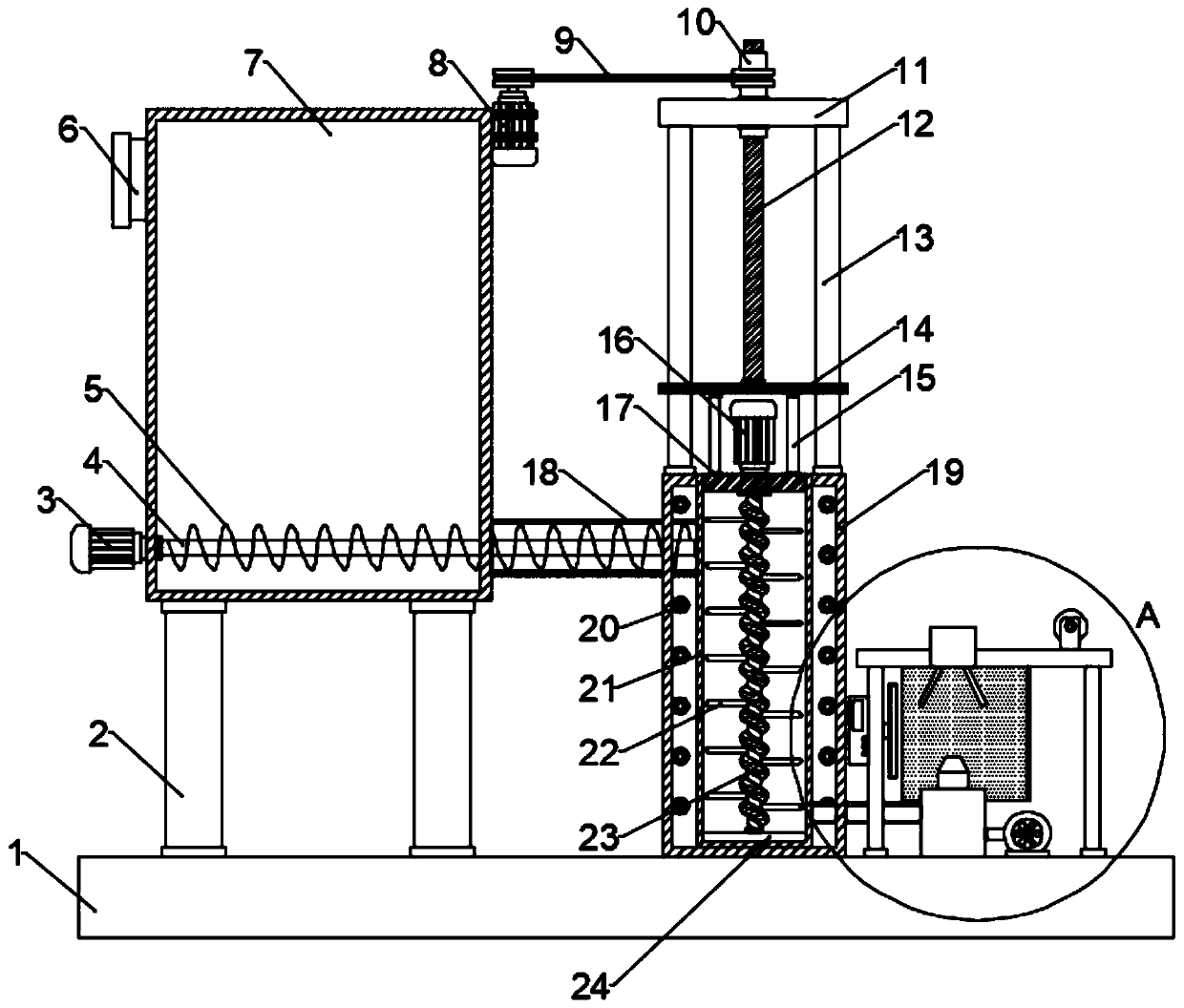

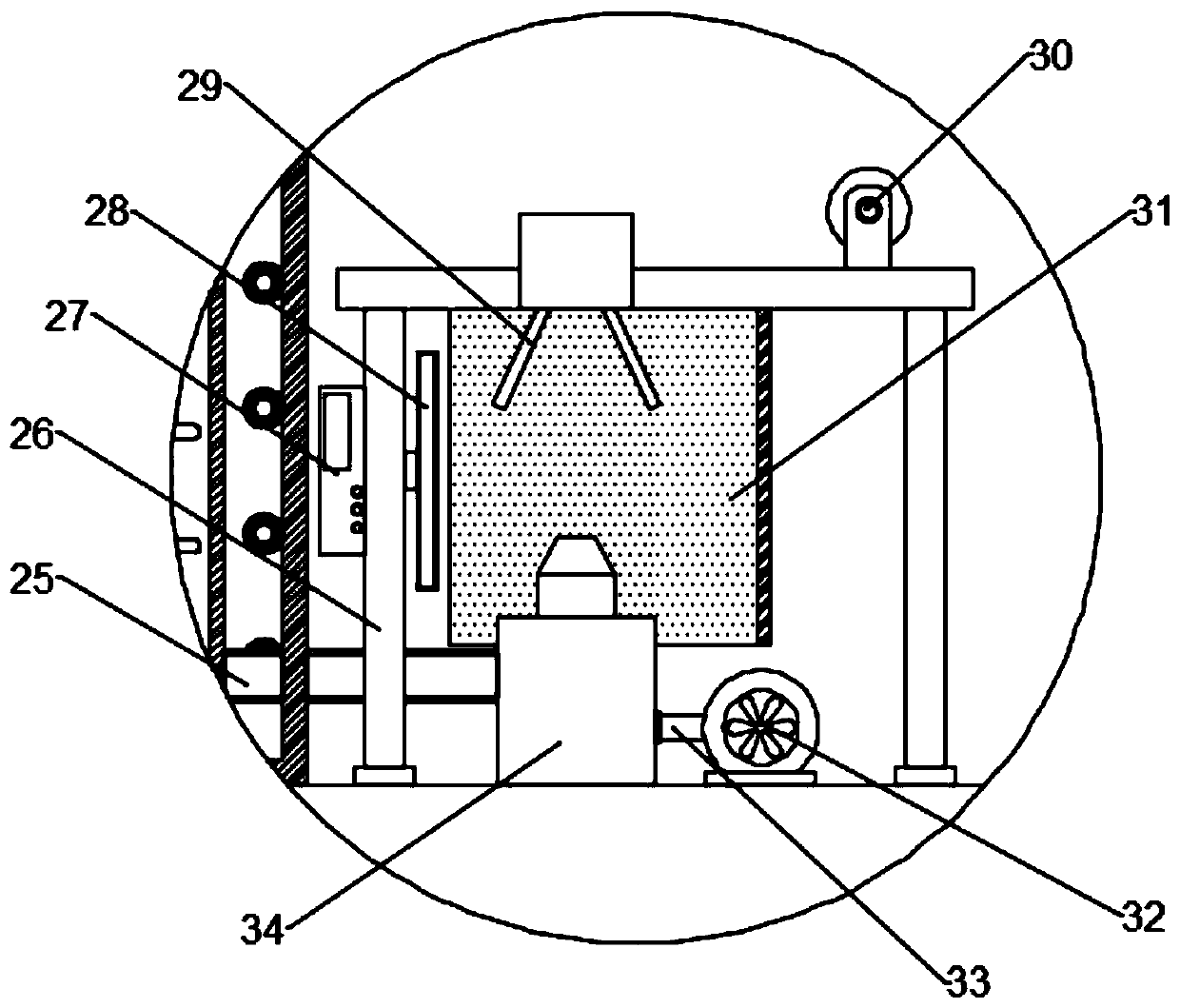

[0024] see figure 1 and figure 2 , in an embodiment of the present invention, a film blowing machine includes a base 1, a storage box 7 and a heating box 19, the storage box 7 is fixed above the base 1 through a plurality of first support rods 2, and the heating box 19 Fixed on the base 1, the upper part of the side wall of the material storage box 7 is provided with a material inlet 6, and a melting box 21 is fixed inside the heating box 19. The melting box 21 is made of metal material, and the side wall of the melting box 21 is provided with a thermal insulation layer, the annular cavity structure formed between the heating box 19 and the melting box 21 is evenly provided with an electromagnetic heating coil 20, and the lower part of the side wall of the material storage box 7 is provided with a material guide tube 18, and the material guide tube 18 is far away from the material storage box 7 One end of the rotating rod 4 extends into the melting tank 21, and the inner wal...

Embodiment 2

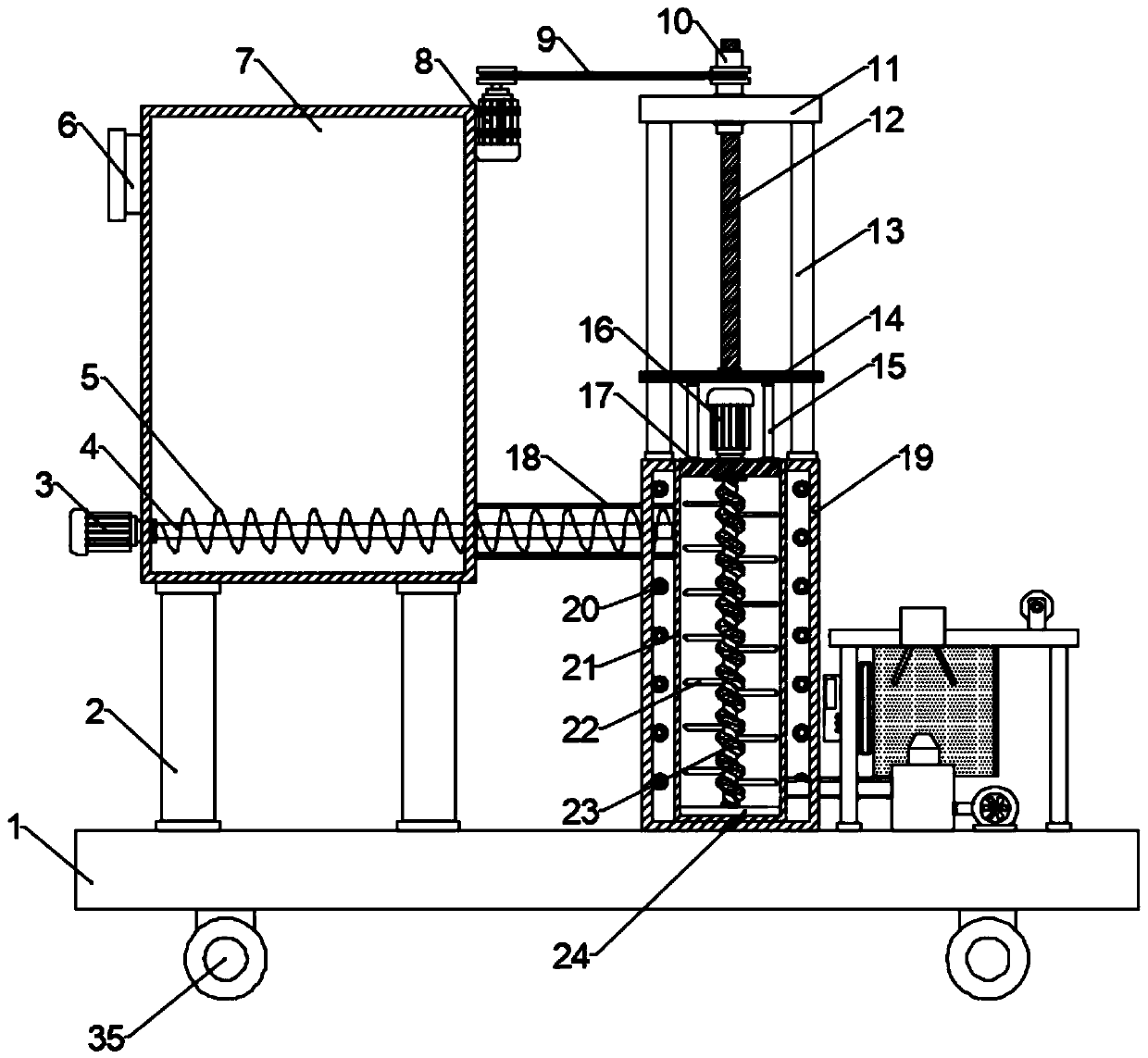

[0031] see image 3The difference between the embodiment of the present invention and embodiment 1 is that, further, in order to facilitate the movement of the device, the bottom of the base 1 is symmetrically provided with rollers 35, and the rollers 35 are self-locking rollers, and each roller 35 is provided with There is a brake assembly, and the staff can easily and conveniently move the device through the rollers 35, which saves time and effort, and is simple and practical.

[0032] The working principle of the present invention is: when the present invention is in use, first pour the plastic raw materials used to make the film into the storage box 7, and then start the first servo motor 3, the third servo motor 16 and the electromagnetic heating The coil 20, the first servo motor 3 drives the rotating rod 4 to rotate so that the screw blade 5 evenly transports the plastic raw materials in the storage box 7 to the melting tank 21 for melting, and the third servo motor 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com