A method and device for automatic marking and weighing

A marking and equipment technology, applied in the field of metal smelting, to save labor, improve work efficiency, and speed up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

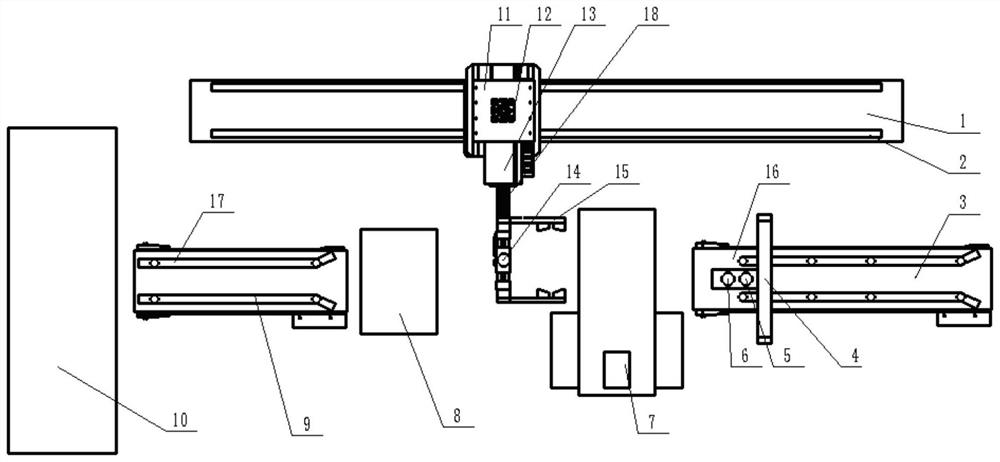

[0038] figure 1 A system block diagram of the equipment for automatic marking and weighing according to the preferred embodiment of the present invention is schematically shown.

[0039] like figure 1 As shown, the system for automatic marking and weighing equipment according to the preferred embodiment of the present invention includes: input conveying device 3, position detection device 6, marking machine 7, manipulator device, weighing unit 8, output conveying device 9. Metal collection box 10. Control system.

[0040] Among them, the input conveying device 3 is used to convey the metal to the next process. For example, the input conveyor 3 includes: a mounting frame 4, a camera 5, a position detection device 6 and a guide 16 for the input conveyor; the mounting frame 4 is installed directly above the metal inflow path of the input conveyor 3, for example, it can span the On the device; the camera 5 is installed on the mounting frame 4; the position detection device and ...

Embodiment 2

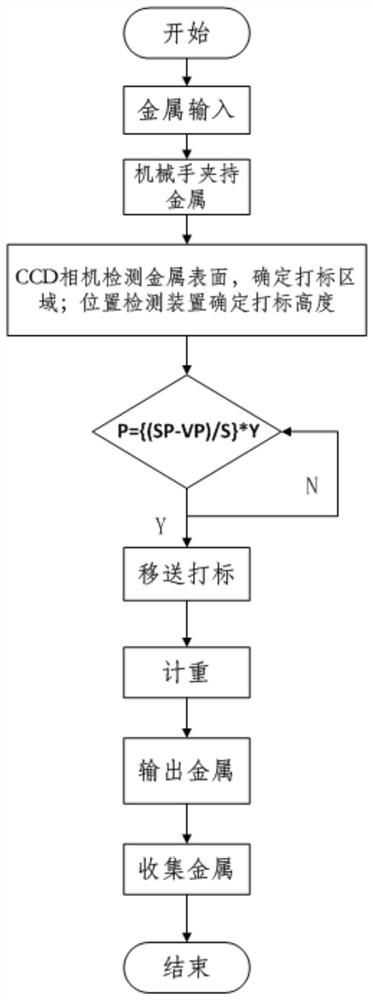

[0053] figure 2 It schematically shows the operation flowchart of a specific example of the method for automating marking and weighing equipment according to the preferred embodiment of the present invention.

[0054] like figure 2 The method for automating marking and weighing equipment according to a preferred embodiment of the present invention includes:

[0055] Metal input: input metal into the equipment through the input conveying device;

[0056] The manipulator grips the metal: the manipulator device follows the system setting, reaches the set point, and grips the metal to the next process;

[0057] The metal is clamped by the manipulator and transferred to the camera for scanning to determine the marking area, and then transferred to the position detection device to determine the marking level that the metal should maintain. The thickness of each piece of metal is uneven. When the metal is too thin, it may exceed the marking machine. The stroke cannot be marked, ...

Embodiment 3

[0064] Compared with Example 1, the output conveying device is canceled, and the manipulator directly clamps the metal and places it in different metal collection boxes. The number of the metal collection boxes is determined according to the quality grade of the metal; it is preferably divided into A, B, and C grades, The grading index is confirmed by the production process index, and this method can be adopted for the case of small production volume. This data can be used to correct the feeding coefficient. There is a theoretical conversion rate between metal weight and oxide. Taking praseodymium neodymium as an example, the conversion rate of praseodymium neodymium metal is 1.175. At this time, the electrolytic furnace is in the best operating state and the product quality is the best. Using this relationship, when the conversion rate is less than 1.1 and the metal grade is C, the setting value of the feeding parameter needs to be multiplied by 1.2; when the metal conversion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com