Method for decoration with stone-like cement artistic decorative material

A decorative material and cement technology, applied in the field of decorative materials, can solve the problems of many processes, consuming a lot of manpower and material resources, and difficult to transport, and achieves the effect of strong artistic expression, rich styles, and reduction of mining and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Stone-like cement art decoration material comprises the following components by weight:

[0028] 300 parts of transparent resin

[0029] 500 parts of white cement powder sieved through a 60-mesh sieve

[0030] 250 parts of fine sand sieved through a 60-mesh sieve

[0031] 1 part of black color paste, 3 parts of brown color paste, 0.2 part of green color paste, and 1 part of gray color paste.

[0032] 1 part of silver powder.

[0033] The decoration process is as follows:

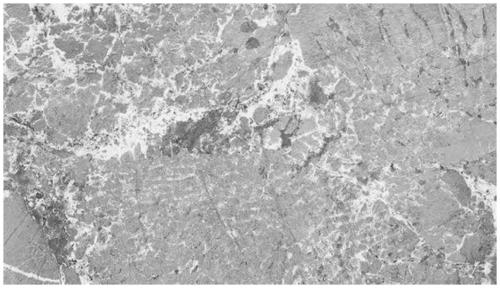

[0034] According to the above ingredient ratio, mix glue a and glue b of epoxy resin ab glue at a ratio of 1:1 and mix it with fine cement, then quickly add fine sand and silver powder, stir evenly, and then blend the color paste, the color paste The different order of adding and the uniform degree of stirring will produce different colors, textures and lines. The uniform and fine texture needs to be stirred more evenly, and a little stirring can produce thick lines and larger color blocks. Add 1...

Embodiment 2

[0039] 250 parts of transparent resin

[0040] 400 parts of white cement powder sieved through a 60-mesh sieve

[0041] 300 parts of fine sand sieved through a 40-mesh sieve

[0042] 1 part of black paste, 3 parts of brown paste, 15 parts of green paste.

[0043] The decoration process is as follows:

[0044] According to the above ingredient ratio, mix glue a and glue b of epoxy resin ab glue at a ratio of 1:1 and then mix it with fine cement, then quickly add fine sand, stir evenly, and then blend the color paste. The process of color paste blending is as follows: add black color paste in turn, stir evenly, then add brown color paste, stir quickly, then add green color paste and stir for a while. After the color paste is blended, apply the blended decorative materials in disorder, and do not polish after drying. The photo of the decorative effect is as follows figure 2 shown.

Embodiment 3

[0046] 300 parts of transparent resin

[0047] 400 parts of white cement powder sieved through a 60-mesh sieve

[0048] 200 parts of fine sand sieved through a 60-mesh sieve

[0049] 20 parts of black paste, 3 parts of yellow paste, 2 parts of white paste.

[0050] The decoration process is as follows:

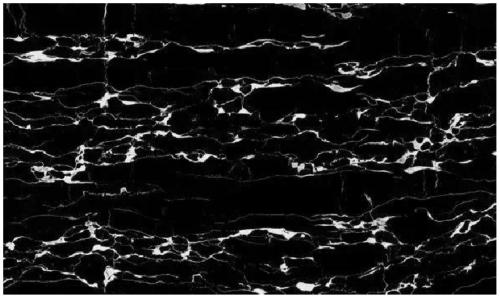

[0051] According to the above ingredient ratio, mix glue a and glue b of epoxy resin ab glue at a ratio of 1:1 and then mix it with fine cement, then quickly add fine sand, stir evenly, and then blend the color paste. The process of color paste blending is as follows: add black color paste, stir evenly, then mix yellow and white color paste evenly, add, and stir slightly. After the color paste is mixed, apply it from left to right without order, and polish it after drying. The photo of the decorative effect is as follows image 3 As shown in , with classical black as the base color, the flowing lines like golden flowers are dazzling and charming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com