High-transparency antibacterial thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and transparency technology, which is applied in the field of high transparency antibacterial thermoplastic polyurethane elastomer and its preparation, can solve the problems of reducing the performance and aesthetics of polyurethane elastomer, easy to grow mildew, poor antibacterial performance, etc., and achieve excellent antibacterial performance And high transparency, good plasticization processing, solve the effect of poor antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

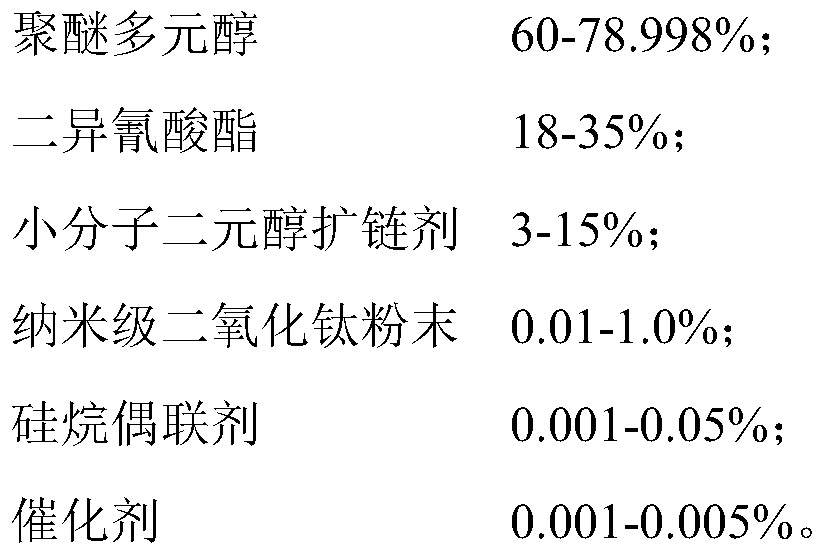

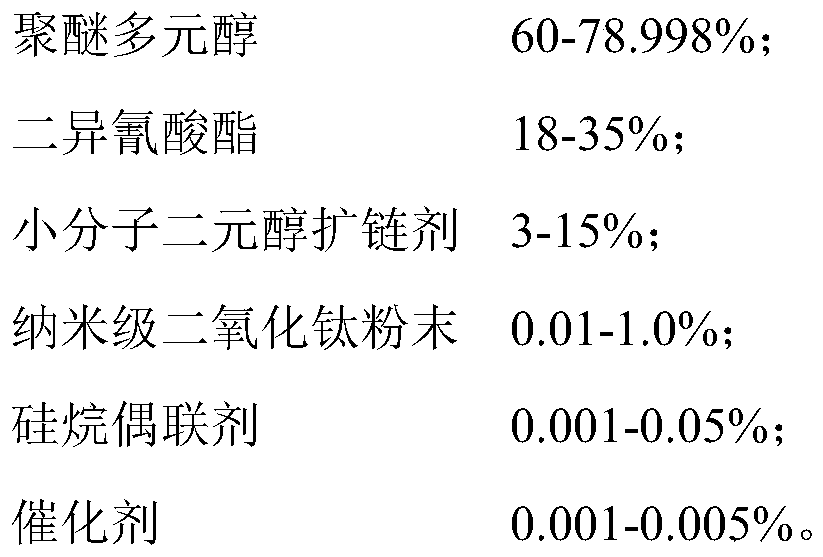

[0023] A kind of highly transparent antibacterial thermoplastic polyurethane elastomer and preparation method thereof:

[0024] 1. Raw material components

[0025] Polyether polyol 62.08%,

[0026] Diisocyanate 30.60%,

[0027] Small molecule diol chain extender 6.78%,

[0028] Nanoscale titanium dioxide powder 0.50%,

[0029] Silane coupling agent 0.01%,

[0030] Catalyst 0.01%.

[0031] 2. Preparation steps:

[0032] a Weigh 0.08g of nano-sized titanium dioxide powder, add it into a conical flask containing 10mL N,N-dimethylformamide, add an appropriate amount of silane coupling agent kh-550 dropwise, and ultrasonically disperse it evenly for 1.5h.

[0033] b Add 9.89g of PTMG-1000 into a three-necked flask equipped with a stirrer, vacuum dehydrate at 110°C for 2h, and then lower the temperature to 80°C.

[0034] c. Add the nanoparticle solution into the three-neck flask, then dropwise add 4.88g IPDI, add dropwise a catalyst, and react at a constant temperature of 90°...

Embodiment 2

[0037] A kind of highly transparent antibacterial thermoplastic polyurethane elastomer and preparation method thereof:

[0038] 1. Raw material components

[0039] Polyether polyol 61.80%,

[0040] Diisocyanate 30.50%,

[0041] Small molecule diol chain extender 6.75%,

[0042] Nanoscale titanium dioxide powder 0.94%,

[0043] Silane coupling agent 0.01%,

[0044] Catalyst 0.01%.

[0045] 2. Preparation steps:

[0046] a Weigh 0.15g of nano-sized titanium dioxide powder, add it to a conical flask containing 10mL N,N-dimethylformamide, add an appropriate amount of silane coupling agent kh-550 dropwise, and ultrasonically disperse it evenly for 1.5h.

[0047] b Add 9.89g of PTMG-1000 into a three-necked flask equipped with a stirrer, vacuum dehydrate at 110°C for 2h, and then lower the temperature to 80°C.

[0048] c. Add the nanoparticle solution into the three-neck flask, then dropwise add 4.88g IPDI, add dropwise a catalyst, and react at a constant temperature of 90° C...

Embodiment 3

[0052] A kind of highly transparent antibacterial thermoplastic polyurethane elastomer and preparation method thereof:

[0053] 1. Raw material components

[0054] Polyether polyol 76.25%,

[0055] Diisocyanate 19.08%,

[0056] Small molecule diol chain extender 5.334.30%,

[0057] Nanoscale titanium dioxide powder 0.36%,

[0058] Silane coupling agent 0.01%,

[0059] Catalyst 0.01%.

[0060] 2. Preparation steps:

[0061] a Weigh 0.08g of nano-sized titanium dioxide powder, add it to a conical flask containing 10mL N,N-dimethylformamide, add an appropriate amount of silane coupling agent kh-550 dropwise, and ultrasonically disperse it evenly for 1.5h.

[0062] b Add 16.86g of PPG-2000 into a three-necked flask equipped with a stirrer, vacuum dehydrate at 110°C for 2h, and then lower the temperature to 80°C.

[0063] c. Add the nanoparticle solution into the three-neck flask, then add 4.22g IPDI dropwise, add 1 drop of catalyst, and react at a constant temperature of 90...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com