Hosiery knitter detection and adjustment method and detection and adjustment device thereof

An adjustment device and adjustment method technology, applied in the field of hosiery, can solve problems such as low detection accuracy, waste of raw materials, troublesome adjustment operations, etc., and achieve the effects of ensuring work efficiency, reducing production costs, and simple adjustment operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

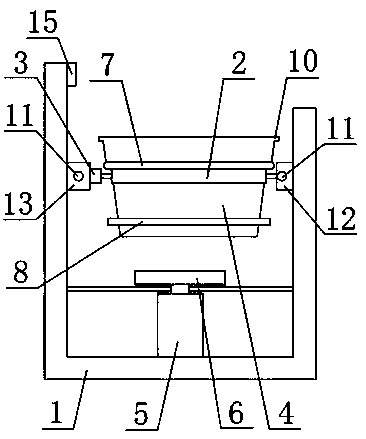

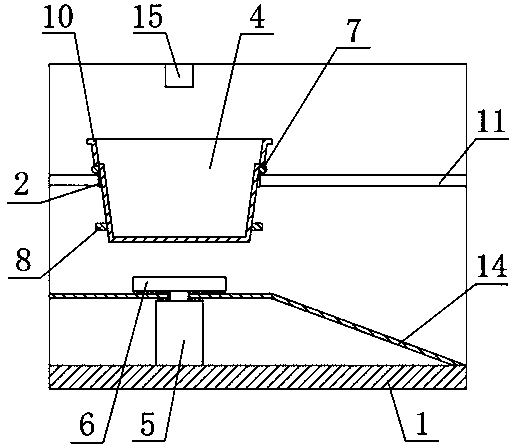

[0038] Examples. A detection and adjustment method for a hosiery machine includes the following steps:

[0039] a. 10s~60s before the sock knitting machine completes socks weaving, the controller controls the lifting cylinder to lift the electronic scale, and the electronic scale lifts the weighing box stuck on the clip until the weighing box and the clip are completely separated. When the electronic scale weighs out the net weight data A of the weighing box, and transmits the data A to the controller;

[0040] b. The controller controls the lifting cylinder to reset, and the weighing box continues to be stuck on the clip after moving down;

[0041] c. The controller controls the electric slider to drive the clamp and the weighing box to move horizontally, so that the weighing box deviates from the top of the electronic scale and is located directly below the sock outlet of the hosiery machine;

[0042] d. The sock knitting machine completes the weaving of the socks, and the socks fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com