A Direct Air Cooling System for Power Plants to Prevent Freezing of Tube Bundles

An air-cooling system and direct technology, applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of easy freezing of countercurrent tube bundles, achieve convenient temperature collection, comprehensive detection range, and avoid freezing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

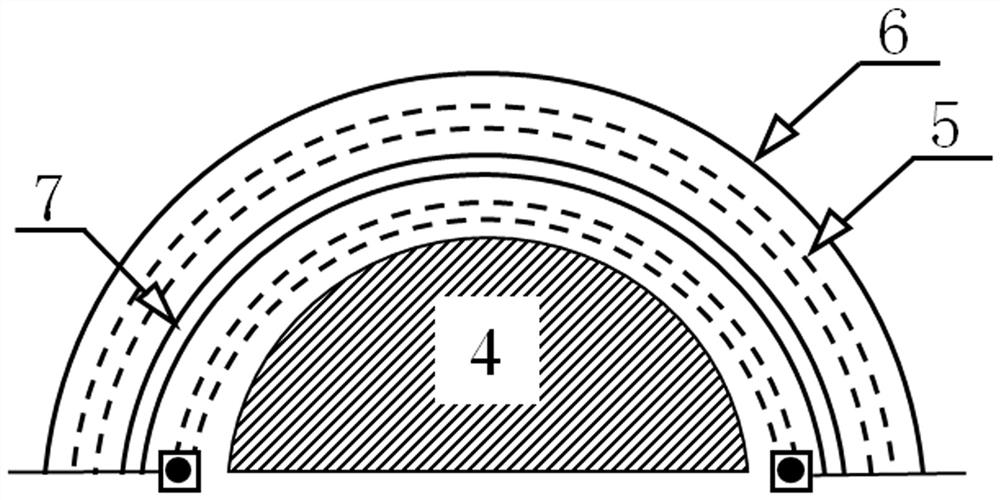

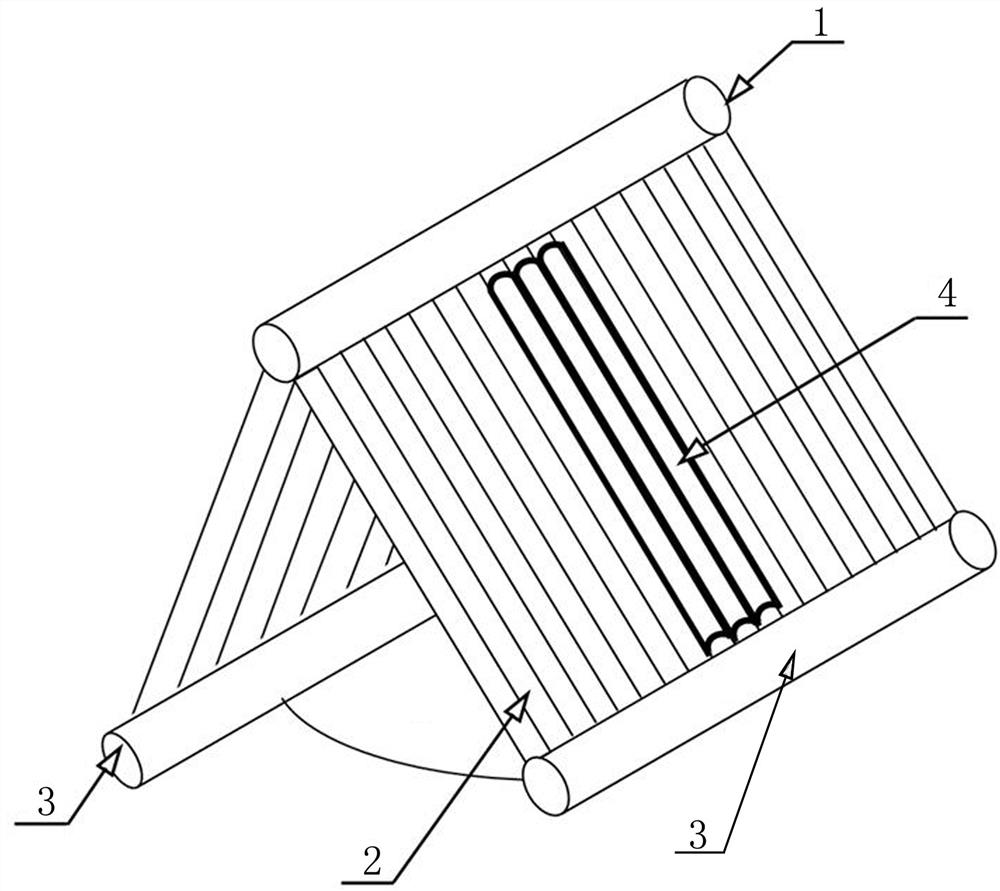

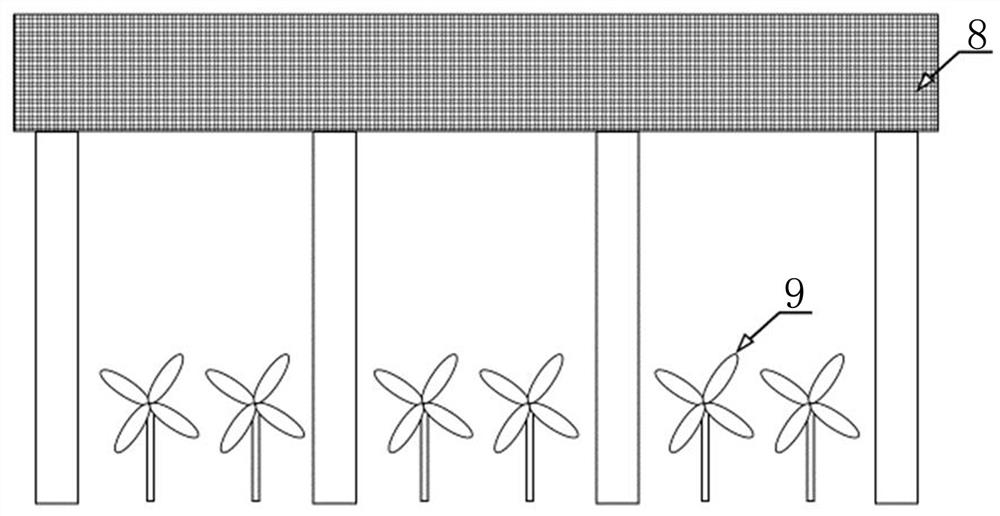

[0016] refer to Figure 1 to Figure 2 , a direct air-cooling system for a power plant that prevents tube bundles from freezing according to the present invention includes an air-cooling island, the air-cooling island is composed of a plurality of air-cooling units, and each air-cooling unit includes a steam distribution pipe 1, a downstream tube bundle 2, a condensation pipe 3, The countercurrent tube bundle 4 and the vacuum device, the steam distribution tube 1 is connected to the downstream tube bundle 2, the downstream tube bundle 2 is connected to the condensation tube 3, the condensation tube 3 is connected to the countercurrent tube bundle 4, and the countercurrent tube bundle 4 is connected to the vacuum device, and the surface of the countercurrent tube bundle 4 is A slide rail arranged along the length direction of the pipeline is added, and a trolley that can move along the slide rail is embedded on the slide rail. Here, the fixing method of the slide rail and the emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com