Irradiation setup for studying chemical diffusion effects between materials

An irradiation device and a technology for researching materials, applied in the field of nuclear fuel, can solve the problems of complex pellet-cladding chemical diffusion mechanism, easy occurrence, damage to the integrity of the radioactive containment barrier of the fuel system, etc., to achieve data detection, simple structure, Improve the effect of shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

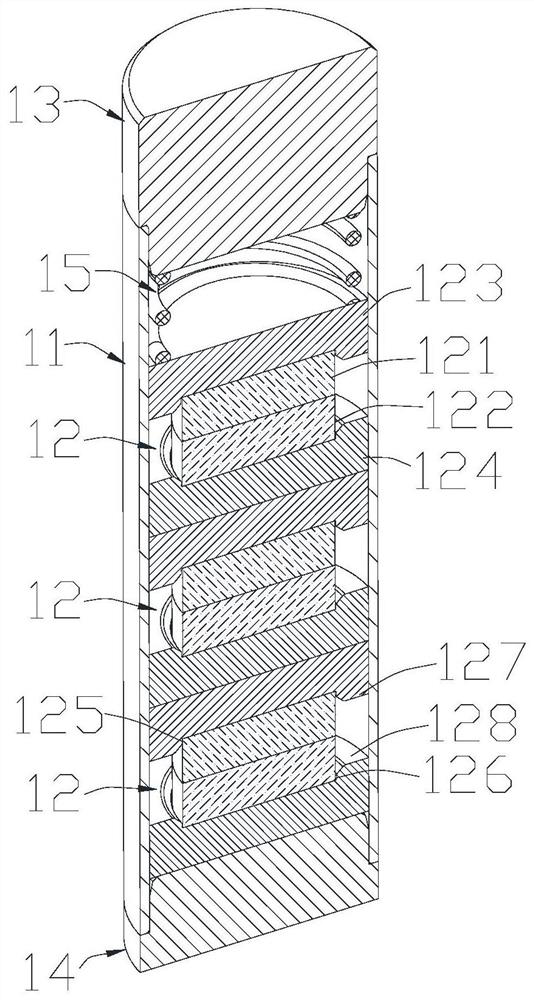

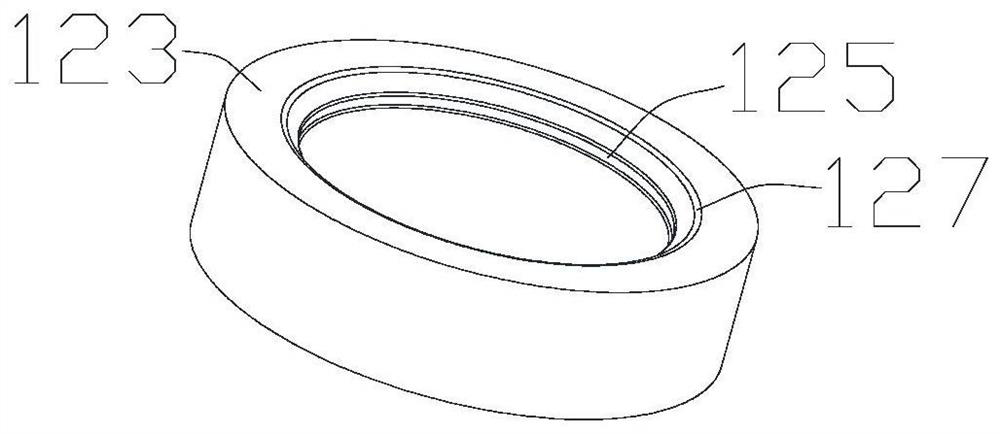

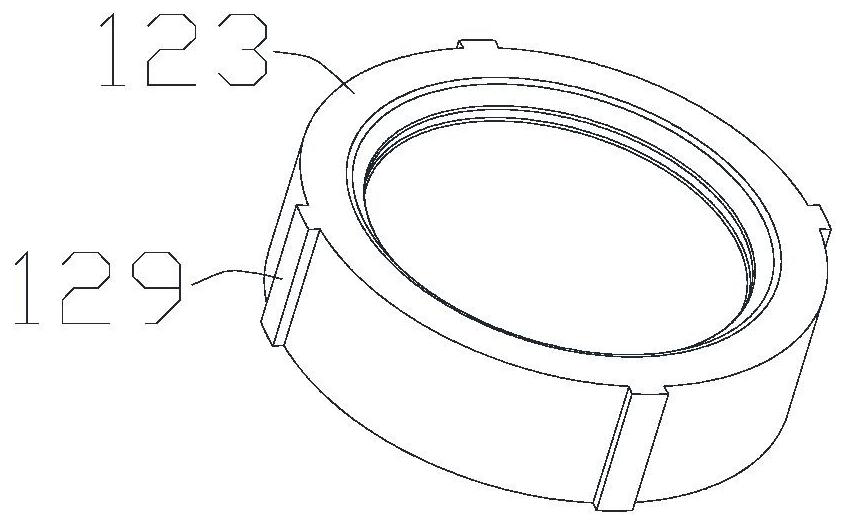

[0035] Such as figure 1 As shown, the irradiation device for studying chemical diffusion between materials according to the first embodiment of the present invention includes a sleeve 11, at least one diffusion coupling unit 12 arranged in the sleeve 11, and two The first end plug 13 , the second end plug 14 , and the elastic buffer 15 .

[0036] Wherein, the overall axial direction of the diffusion coupling unit 12 is parallel to the axial direction of the sleeve 11 . When there are multiple diffusion coupling units 12 , the multiple diffusion coupling units 12 are arranged inside the sleeve 11 along the axial direction of the sleeve 11 . The arrangement of the first end plug 13 and the second end plug 14 at both end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com