Method for simulating oxygen content distribution of high-temperature carbonization furnace based on ANSYS

A technology of high-temperature carbonization furnace and simulation method, which is applied in design optimization/simulation, CAD circuit design, computer-aided design, etc. It can solve the problems of high purchase price, use and quantity limitation, etc., to reduce design cost and measure structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and preferred specific embodiments of the present invention.

[0032] A method for simulating oxygen content distribution in a high-temperature carbonization furnace based on ANSYS disclosed in the present invention includes the following steps:

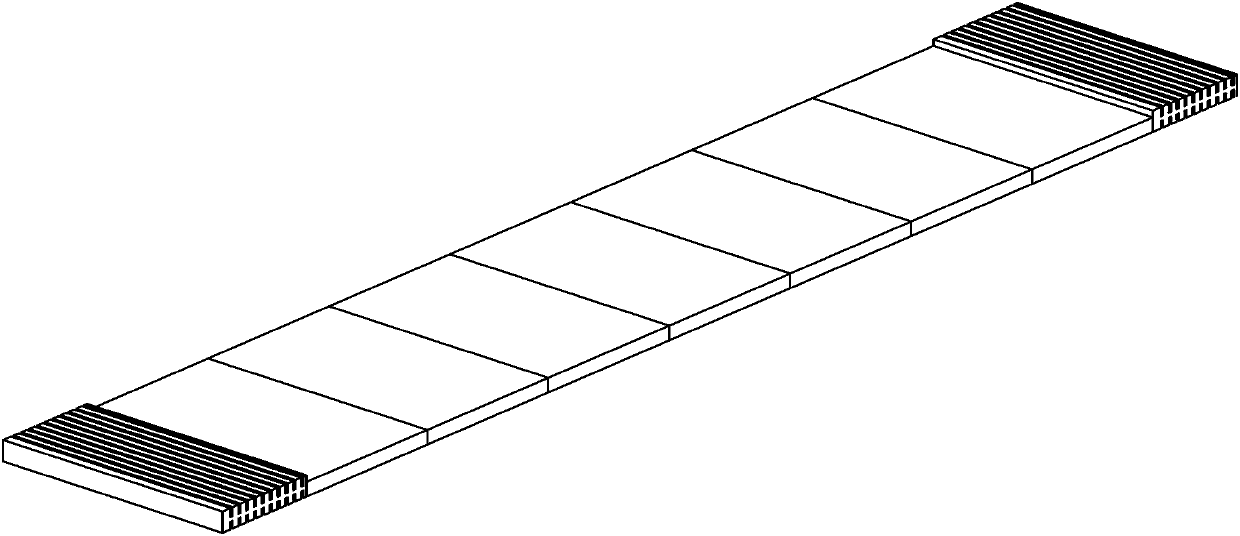

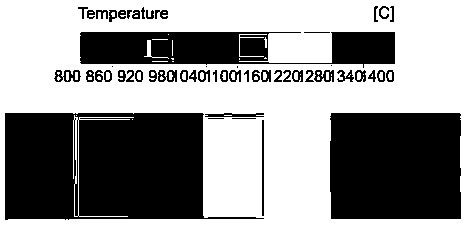

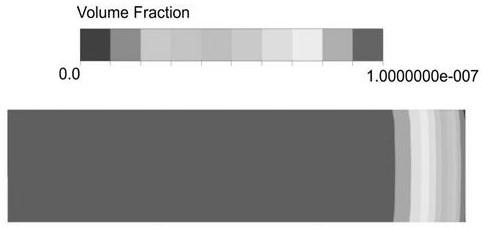

[0033] S1. Use 3D software to establish a 3D simulation model of the high temperature carbonization furnace muffle cavity and the inlet and outlet sealing cavity, such as figure 1 , and set the parameters of the 3D simulation model;

[0034] Specifically, the three-dimensional computer-aided design software SOLIDWORKS can be used to establish a three-dimensional simulation model of the high-temperature carbonization furnace muffle cavity and the inlet and outlet sealing cavity, and set the geometric parameters of all three-dimensional simulation models; the geometric parameters set by the three-dimensional simulation model inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com