Image evolution analysis method based on deep learning

A deep learning and analysis method technology, applied in the field of image processing, can solve the problem that the operator cannot intuitively see the specific state of the dust accumulation of the air preheater rotor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

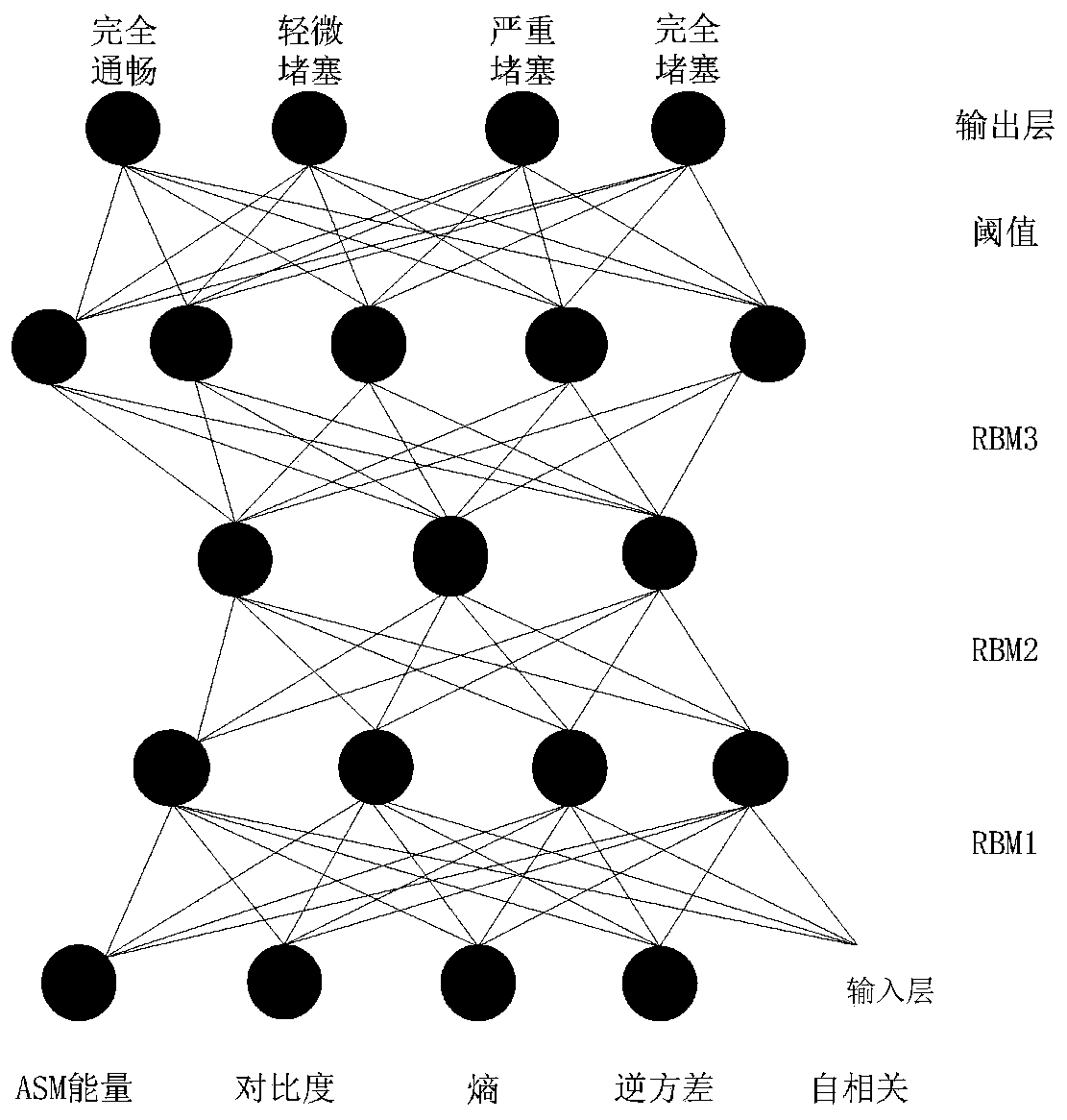

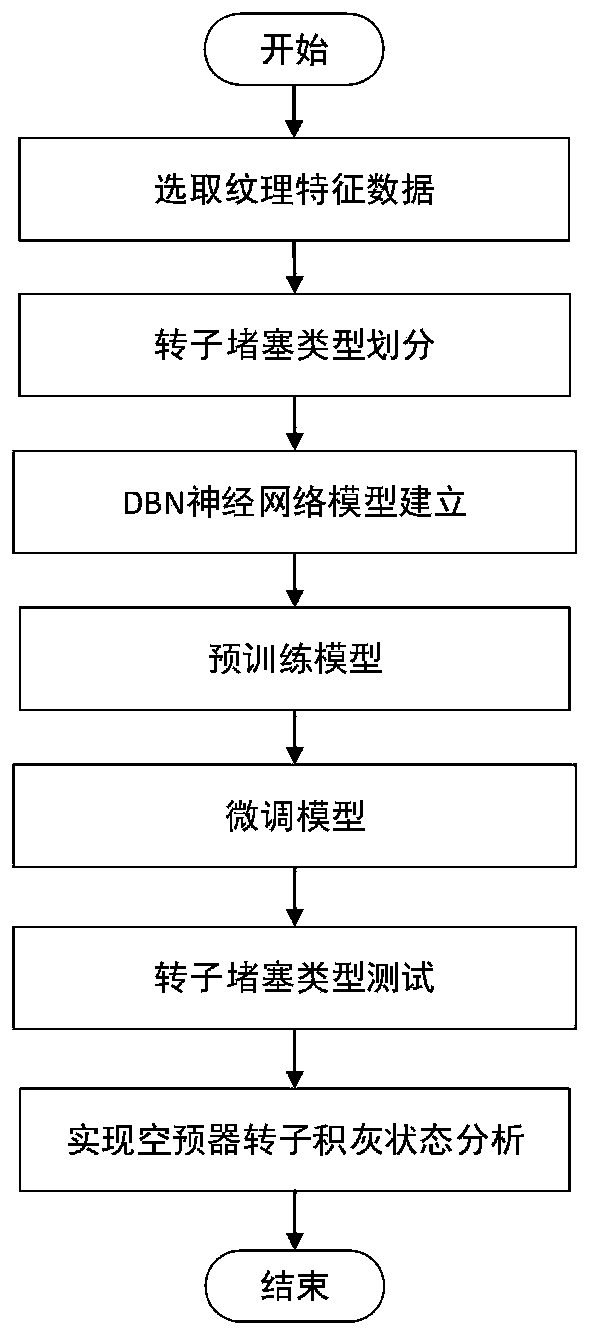

[0099] The present invention adopts the following technical solutions: provide an image evolution analysis method based on deep learning, on the basis of infrared images, based on the relevant texture features extracted by the gray level co-occurrence matrix, and adopt deep learning algorithms to accurately analyze the air preheater rotor The soot accumulation status can guide the operator to optimize the operation of the soot blowing system and improve the work efficiency of the air preheater during normal operation.

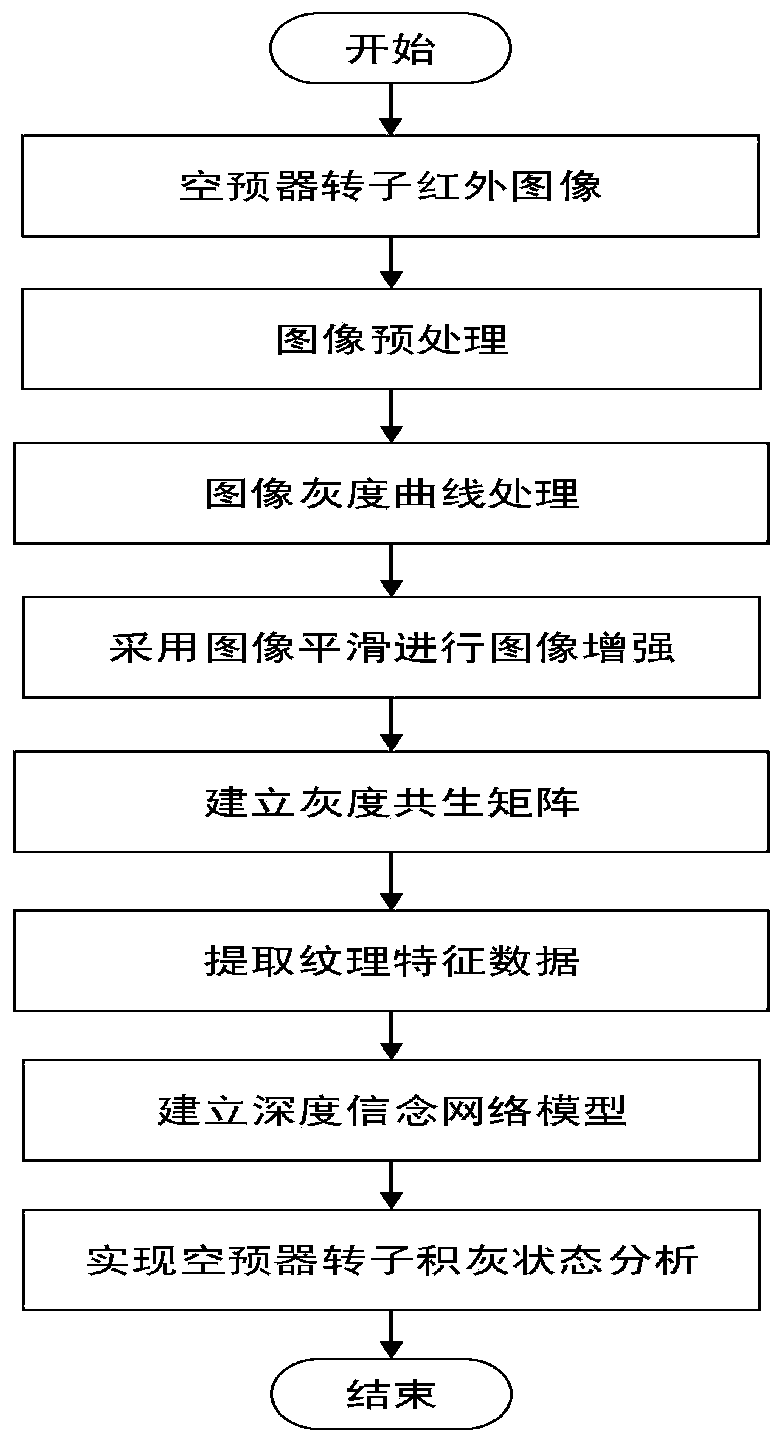

[0100] Such as figure 1 As shown, the method for analyzing the evolution of dust accumulation in the rotor image of the air preheater based on deep learning includes the following steps:

[0101] The infrared thermal imager installed on the air preheater is used to obtain the infrared image of the air preheater rotor; the infrared imaging technology can convert the invisible infrared energy emitted by the object into a visible infrared thermal image, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com