Automatic production line for connector terminals, and process thereof

An automatic production line and connector terminal technology, applied in connection, contact manufacturing, circuit/collector components, etc., can solve the problems of low welding efficiency and high labor cost, and achieve small operating space, precise welding, and large operating range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

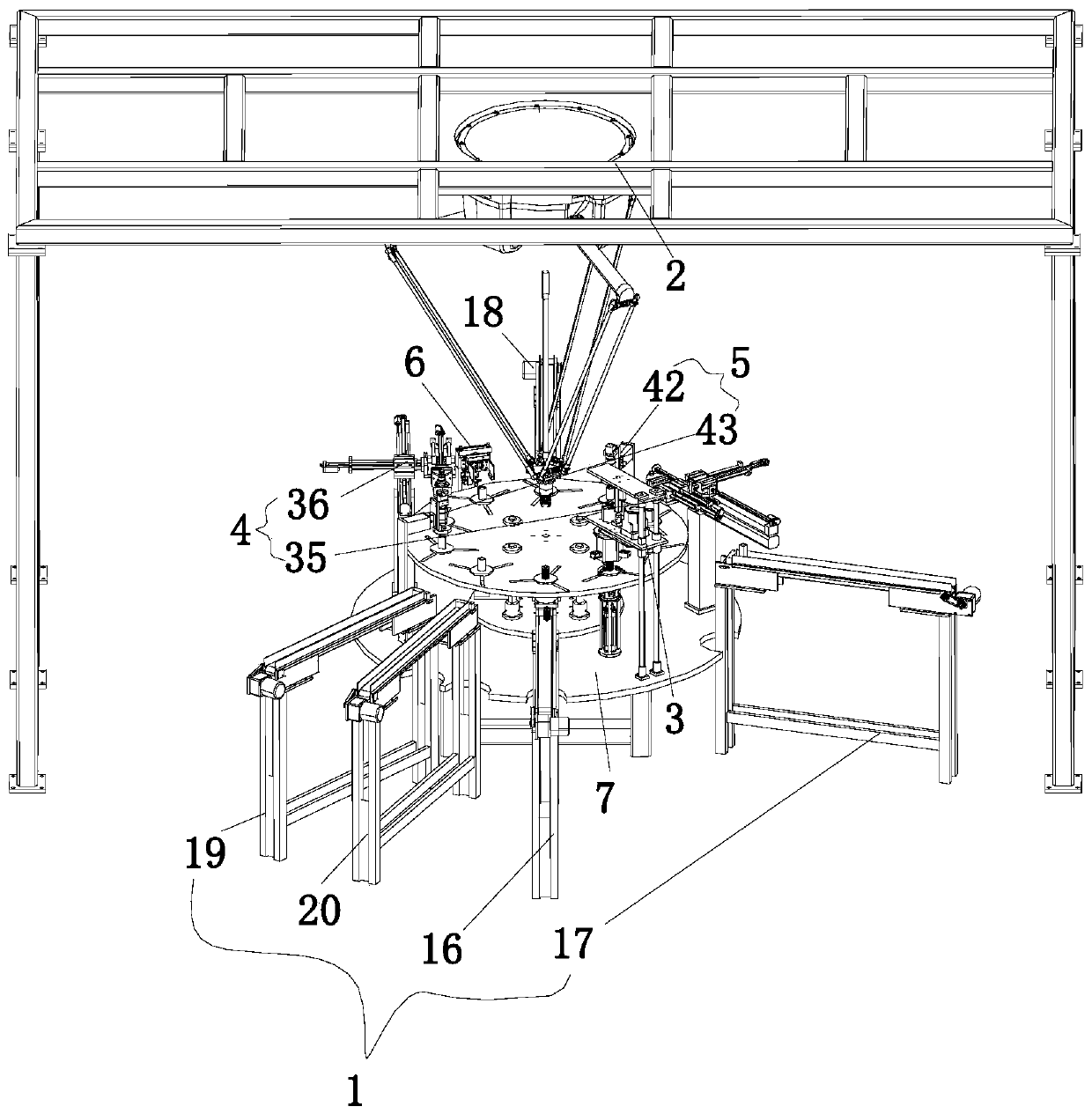

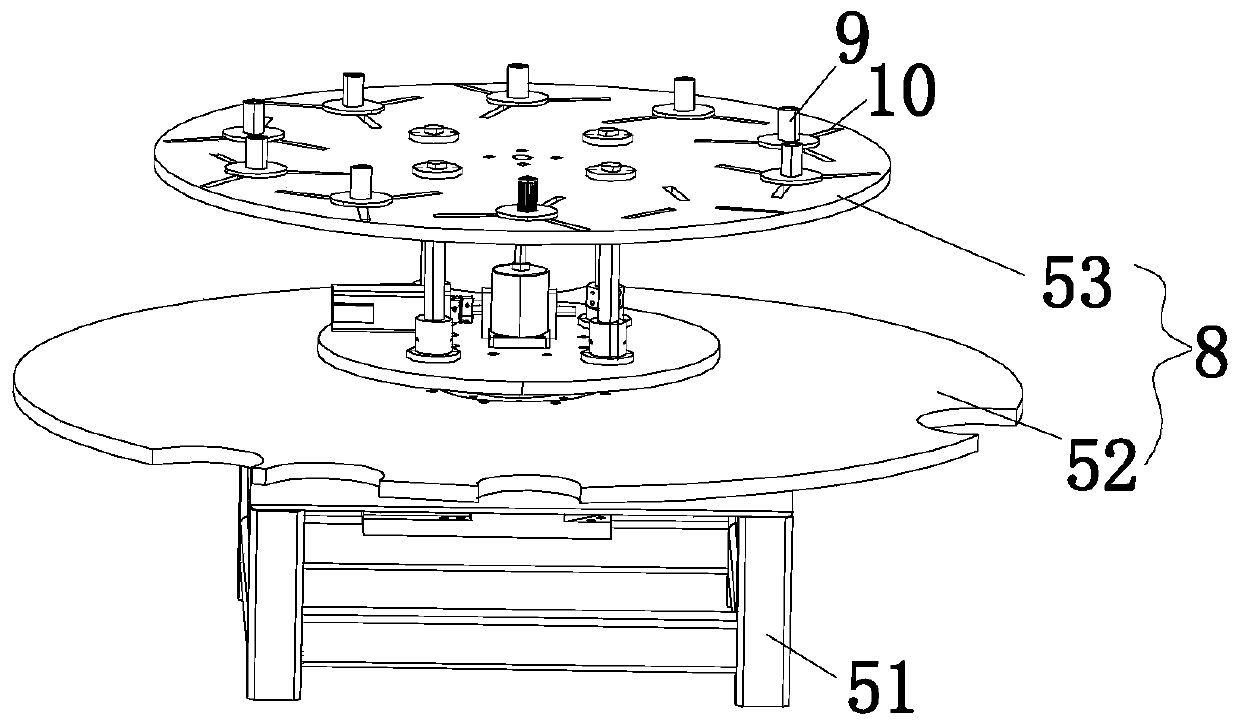

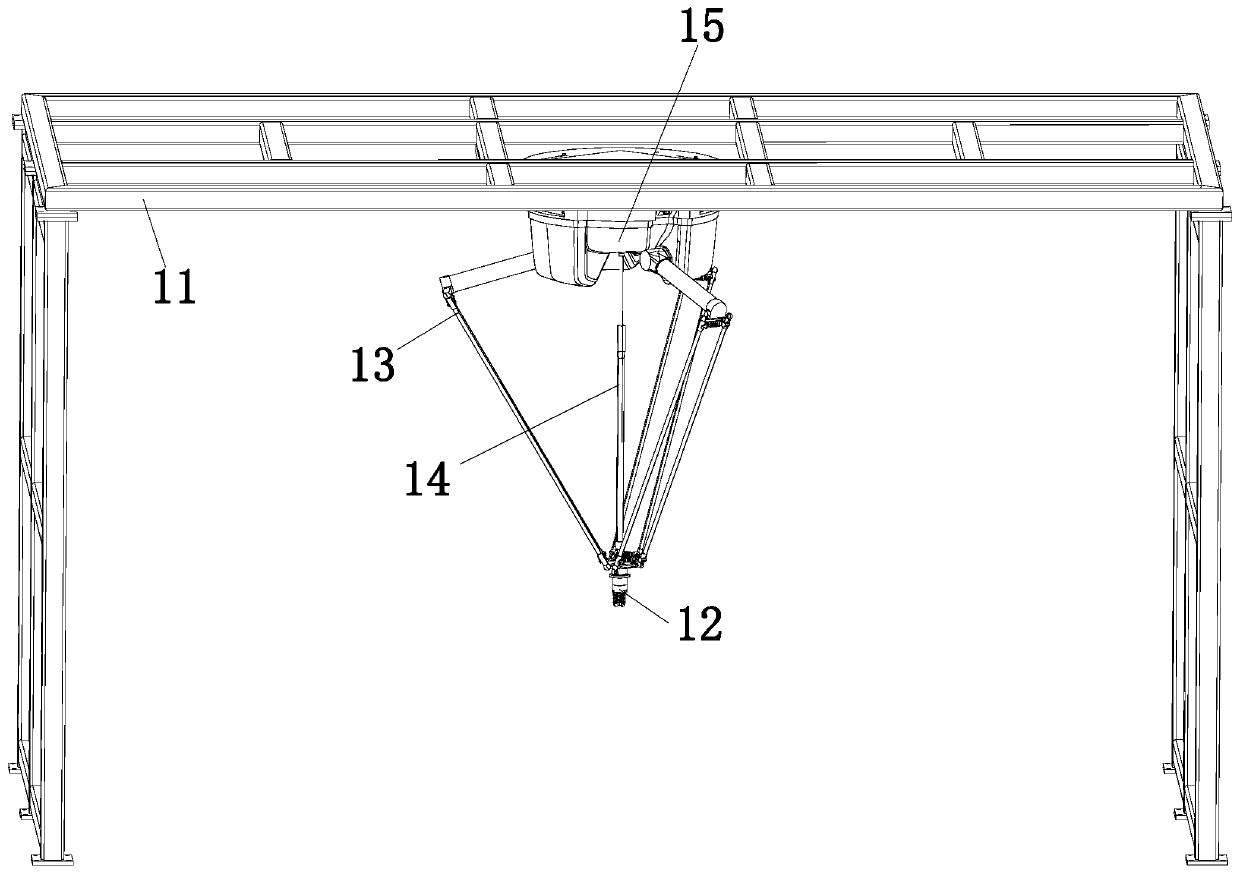

[0038] Combine below Figure 1 to Figure 11 As shown, the embodiment of the present invention provides an automatic production line for connector terminals, including a narrow conveyor belt 1, a spider manipulator 2, a twisting mechanism 3, a welding mechanism 4, a detection mechanism 5, a turning mechanism 6, and a platform 7. The platform 7 is designed In the middle of the whole equipment, the narrow-distance conveyor belt 1 is arranged around the platform 7, and the spider-man manipulator 2 is arranged on the upper part of the platform 7 and the spider-man manipulator 2 can be placed on the narrow-distance conveyer belt 1, the twist-and-pull mechanism 3. Working on the welding mechanism 4, the detection mechanism 5, the turning mechanism 6 and the platform 7, the twisting and pulling mechanism 3, the welding mechanism 4, and the turning mechanism 6 are successively arranged at the fixed position on the upper edge of the platform 7, each The structures are coordinated with e...

Embodiment 2

[0054] The connector automatic production line described in embodiment 1 comprises the following steps:

[0055] In the first step, the elastic grid is firmly placed on the tooling 9 at the corresponding position through the mechanical claw 12, and the movable plate 53 starts to rotate counterclockwise;

[0056] In the second step, when the elastic grid reaches the twist-pull mechanism 3, first start the lower cylinder 21 to stretch out the output end, release the grasping finger 57, place the elastic grid and tooling 9 on the grasping palm 58, and contract the lower cylinder 21, clamp the lower end of the elastic grid, and then start the electric cylinder 22, the output end of the electric cylinder 22 descends to drive the twist-pull cover 26, and the twist-pull cover 26 covers the elastic grid, and starts the thumb Cylinder 25, the output shaft 54 drives the fixed claw 55 to move inwardly under the action of the thumb cylinder 25, the fixed claw 55 clamps the upper end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com