Concentrated winding transverse flux permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and transverse magnetic flux, which is applied to synchronous machines, synchronous motors with stationary armatures and rotating magnets, windings, etc., which can solve the problems of copper loss and only function as a connection, and improve utilization Ratio, improvement of winding utilization, and improvement of cogging torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

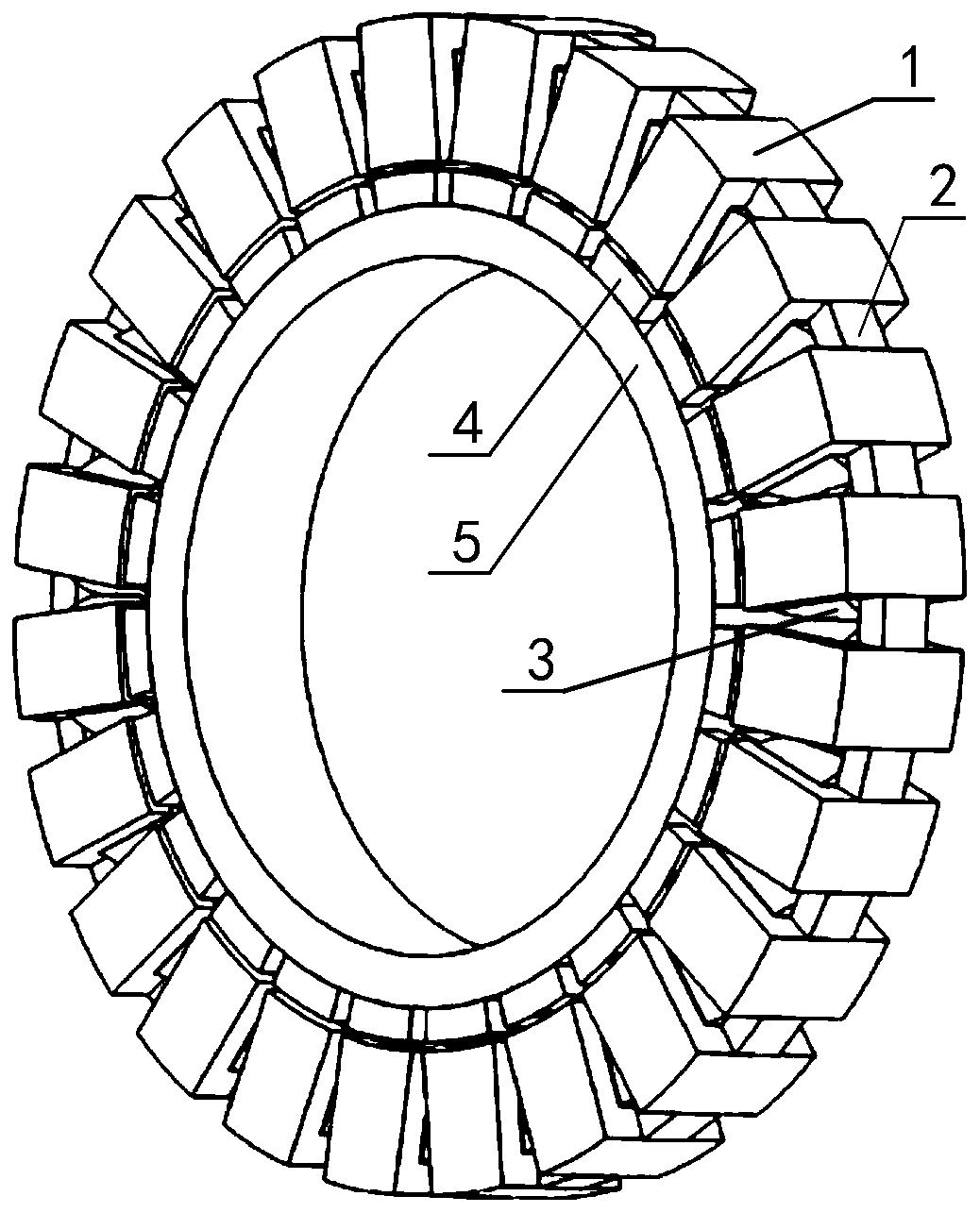

[0029] figure 1 It is a three-dimensional schematic diagram of a single-phase motor with concentrated winding transverse flux permanent magnet synchronous motor in this embodiment, including a stator part and a rotor part, and the stator part includes a stator "E" tooth 1, a stator yoke part 2 and a stator winding 3 , the rotor part includes the rotor magnetic steel 4 and the rotor yoke 5, and there is an air gap between the stator and the rotor. In this embodiment, the number of pole pairs P 1 12, the number of stator teeth is 2P 1 24, number of coils 2P 1 for 24.

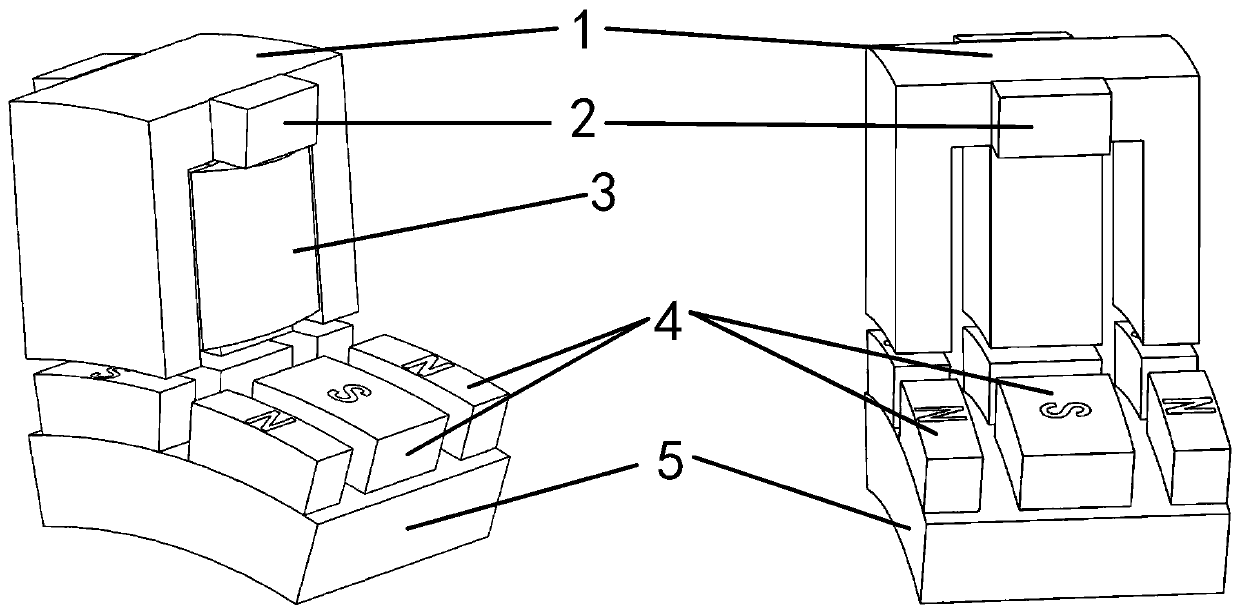

[0030] figure 2 It is a partially enlarged schematic diagram of a single-phase motor with concentrated winding transverse flux permanent magnet synchronous motor in this embodiment. The left and right diagrams are from different perspectives and the stator winding 3 is hidden in the right diagram. In the figure, the stator "E" tooth 1 and the stator yoke 2 only show one pole (that is, the 1 / 24 stator core mo...

Embodiment 2

[0039] Figure 5 It is a three-dimensional structural schematic diagram of a concentrated winding transverse flux permanent magnet synchronous motor in this embodiment. The three-phase motor is composed of three identical single-phase motors connected in series axially. Each phase motor includes stator "E" tooth 1, stator yoke 2, stator winding 3, rotor magnetic steel 4 and rotor yoke 5, A-phase motor 10, B-phase motor 11, and C-phase motor 12 are identical, three The phases are connected in series in the axial direction, and the stator parts are staggered by 120° in the same direction.

[0040] Figure 6 It is a three-dimensional schematic diagram of the stator winding of a three-phase motor with concentrated winding transverse flux permanent magnet synchronous motor in this embodiment, and the A-phase winding 13, B-phase winding 14, and C-phase winding 15 are sequentially staggered by 120°.

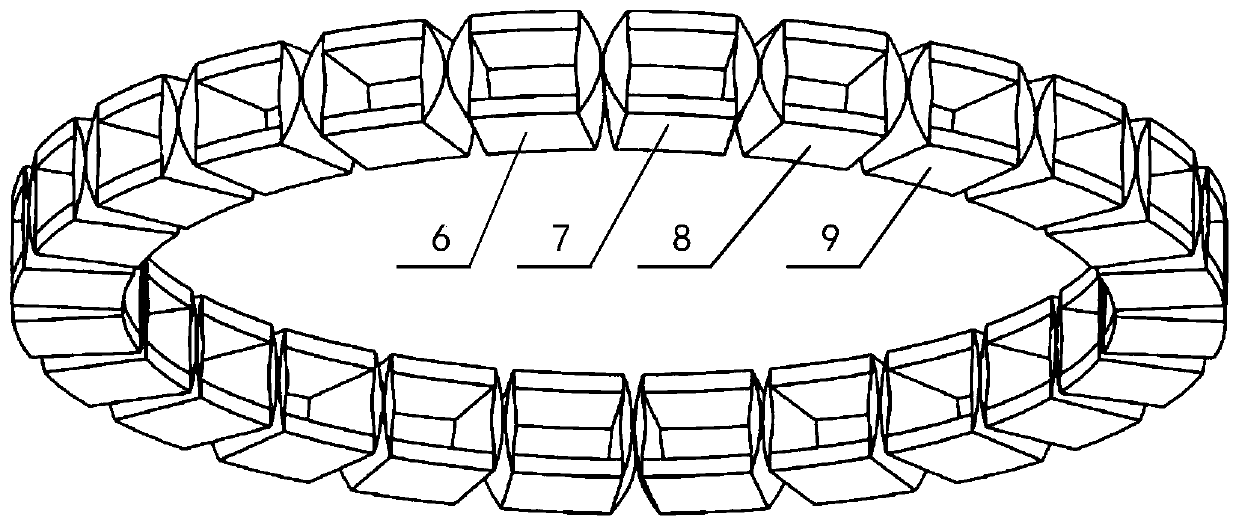

[0041] Figure 7 It is a three-dimensional structural schematic diagram of the r...

Embodiment 3

[0044] Figure 8 It is a schematic diagram of a single-phase motor explosion of a concentrated winding transverse flux permanent magnet synchronous motor in this embodiment. In the actual assembly process, the stator "E" type teeth 1 can be divided into "C" type iron core teeth 19 and intermediate teeth The two parts of 21, the stator yoke 20 and the middle tooth 21 can be realized by axial lamination, and at the same time, the "C" type iron core teeth 19 can be fixed, which solves the problem that the stator teeth of the traditional transverse flux motor are separated from each other and are not easy to fix . In this implementation manner, the "C"-shaped iron core teeth 19 can also be realized by "C"-shaped laminations arranged in the circumferential direction, which avoids the use of a special soft magnetic composite material core and has more practical value. The stator winding 22 and the rotor magnetic steel 23 have not changed. In order to avoid the excessive iron loss o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com