High-yield and high-quality cultivation method of kale under plant factory conditions

A technology of kale and its cultivation method, which is applied in the field of high-yield and high-quality cultivation of kale under plant factory conditions, can solve problems such as nitrate accumulation, premature aging of plants, and yellowing of lower leaves, and achieve optimal growth environment, rich nutrients, and quality Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] The plant factory laboratory has three independent plant factories that can carry out test treatments at the same time. Each plant factory is equipped with 6 sets of aluminum profile assembled cultivation frames, three-layer structure, the layer spacing is 50cm, and the size is 1200mm long * 660mm wide * 2350mm high. Each group of cultivation racks has an independent circulation system, and the liquid supply and return method of each layer is concentrated.

[0061] The intelligent plant factory IoT mobile phone APP control interface can realize remote detection and control of environmental data, light intensity, temperature, humidity, CO 2 Concentration, nutrient solution EC, pH value, etc.

[0062] The day and night (12 hours of light and 12 hours of darkness) temperature in the plant factory is 25±1°C / 22±1°C, the humidity is 65%, CO 2 Concentration of outside atmospheric CO 2 Concentration, the intensity of light is 200μmol·m -2 ·s -1 .

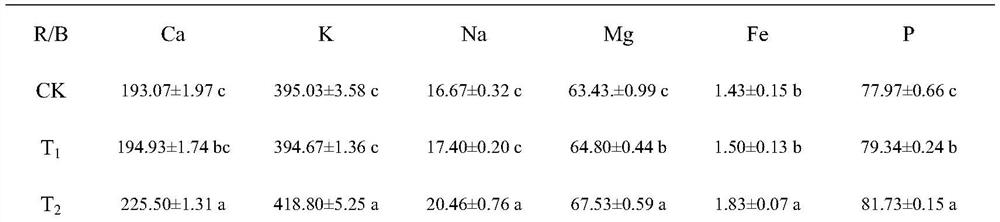

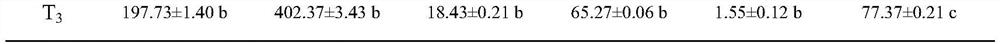

[0063] The kale (Brassic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com