Forming machining method for composite building heat insulating plates

A molding processing and building insulation technology, which is applied to flat products, household appliances, and other household appliances, etc., can solve problems such as inability to ensure the uniformity of the opposite side, cumbersome work process, and increase economic costs, so as to achieve uniform and complete flatness , enhance the effect of positioning, improve the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

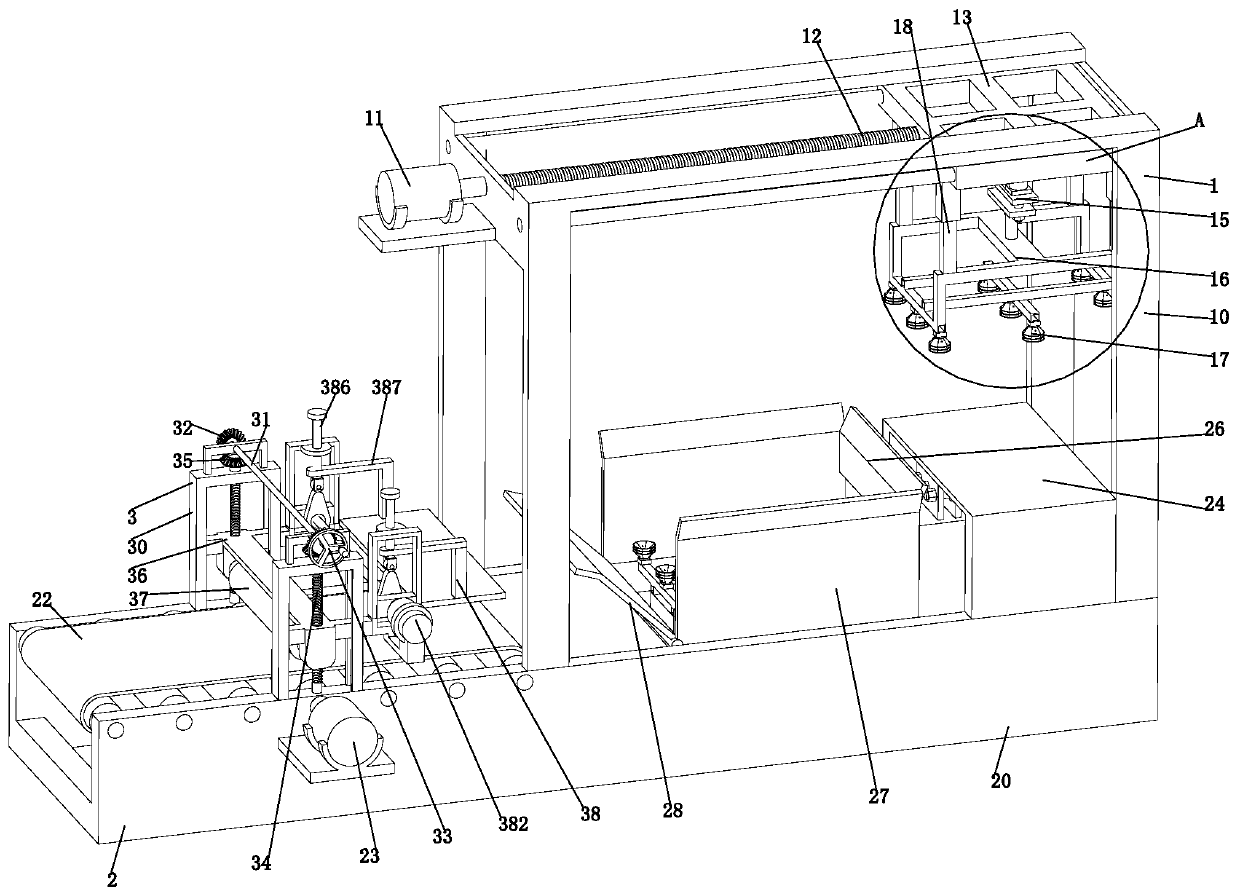

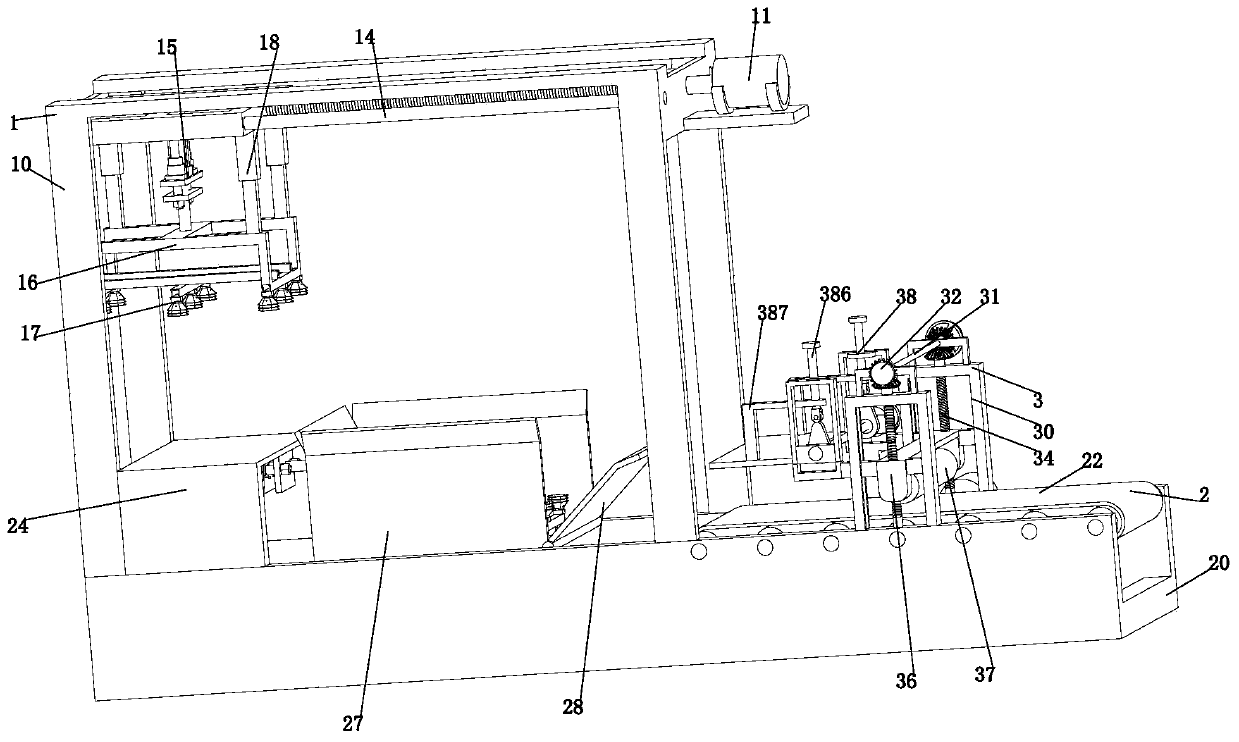

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific drawings. It should be noted that, in the case of no conflict, the embodiments and Features in the embodiments can be combined with each other.

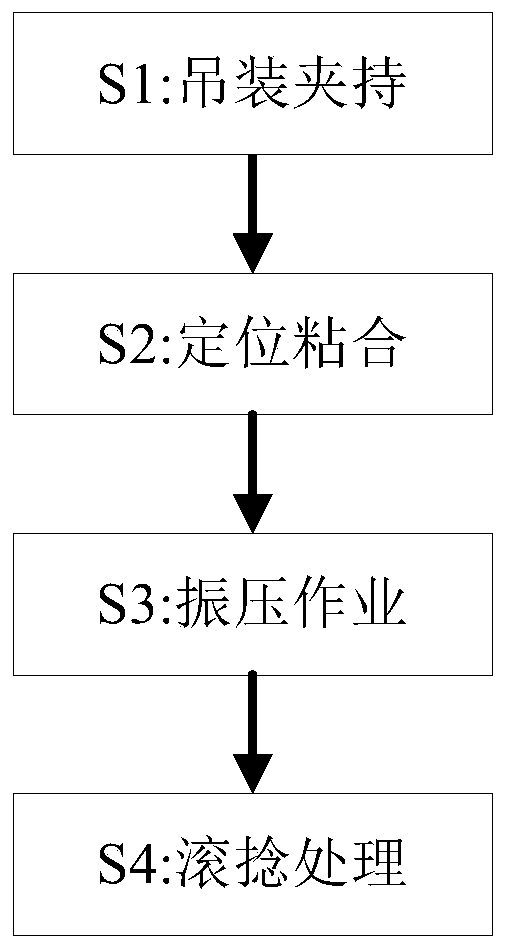

[0029] Such as Figure 1 to Figure 6 As shown, a composite building insulation board molding processing method, which uses a composite building insulation board molding processing equipment, the molding processing equipment includes a lifting mechanism 1, a bonding mechanism 2 and an actuator 3, using the above The specific method for forming composite building insulation boards by forming processing equipment is as follows:

[0030] S1. Hoisting and clamping: Adsorb the panel through the lifting suction cup 17, and then control the moving distance of the adsorption panel through the transmission screw 12, and transp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap