Method for supplementing chlorine to secondary water supply and storage equipment

A technology for secondary water supply and supplementation, applied in chemical instruments and methods, water/sludge/sewage treatment, sterilization/microdynamic water/sewage treatment, etc. It can reduce the risk of corrosion, facilitate transportation and installation, and increase the concentration of residual chlorine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

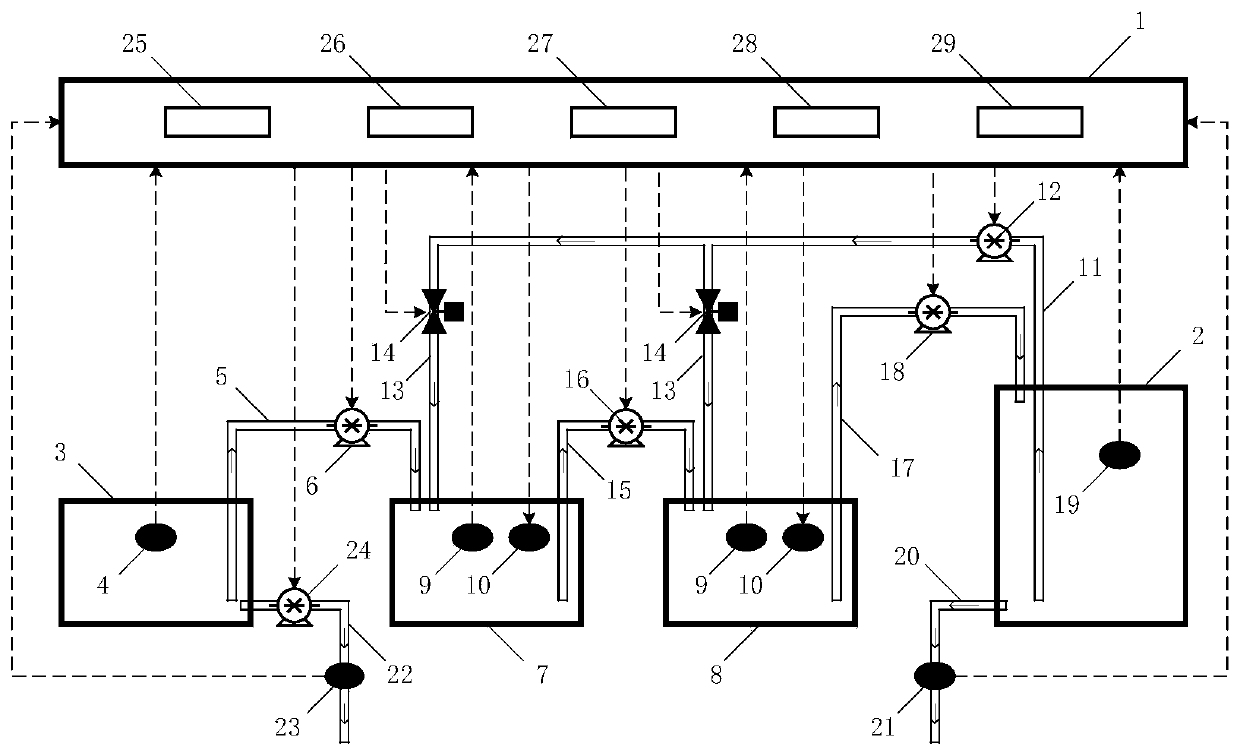

[0033] The invention provides a method for adding chlorine to secondary water supply and storage equipment, such as figure 1 As shown, the equipment or devices used in the supplementary chlorine method include a stock solution storage and sampling device, a dilution dosing device, a monitoring device and an intelligent controller 1 . The stock solution storage sampling device comprises a stock solution storage tank 3, a storage tank water level switch 4 and a sampling assembly, wherein the sampling assembly includes a sampling tube 5 and a sampling pump 6 arranged on the sampling tube 5; the dilution dosing device comprises a first dilution tank 7, a Two dilution tanks 8, water adding components, liquid adding components and dosing components, the first dilution tank 7 and the second dilution tank 8 are equipped with a water level switch 9 and an agitator 10 in the dilution tanks, and the water adding components include a water adding main pipe 11 and a water adding pump 12. T...

Embodiment 2

[0052] On the basis of Embodiment 1, this embodiment is further described in conjunction with specific data, assuming that the volume of the managed water tank 2 is 5*3*2=30m 3 , the horizontal longitudinal section area is 5×3=15m 2 .

[0053] Specifically, in the step S1, a low-range online residual chlorine meter is used to monitor the residual chlorine concentration of the tap water in the water tank 2 in real time, and the residual chlorine safety value is set to 0.15 mg / L. The residual chlorine concentration of the tap water is reduced to 0.15 mg / L, so the intelligent controller 1 starts to add chlorine to the tap water in the water tank 2.

[0054] In the step S2, the sensor for detecting the available chlorine content of the sodium hypochlorite stock solution is a high-range on-line sodium hypochlorite detector 23 specially used to detect the available chlorine content of the high-concentration sodium hypochlorite stock solution. The usual sodium hypochlorite detector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com