Polyvinyl chloride plastic adhesive and preparation method thereof

A polyvinyl chloride and adhesive technology, applied in the direction of adhesives, etc., can solve the problems of large amount of solvent, high cost, poor solubility of PVC resin, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

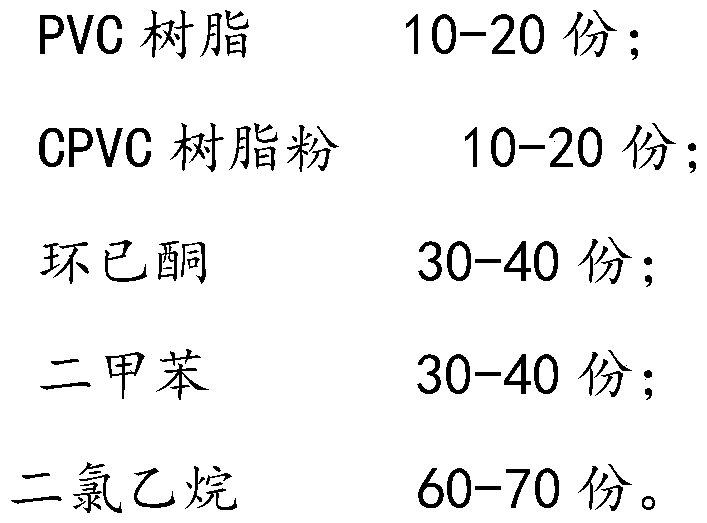

[0030] Embodiment 1: a kind of polyvinyl chloride plastic adhesive, comprises the raw material of following parts by weight:

[0031]

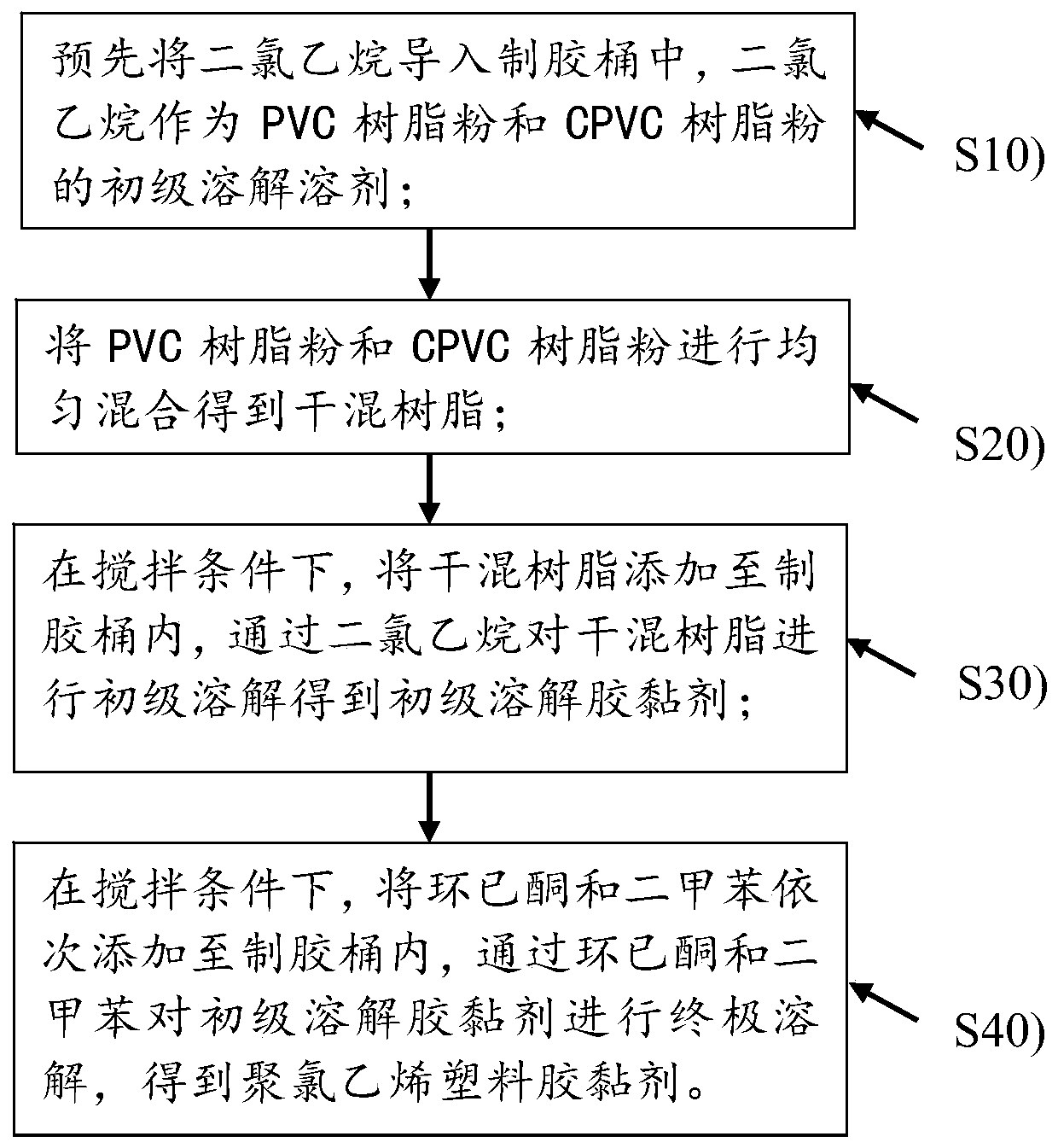

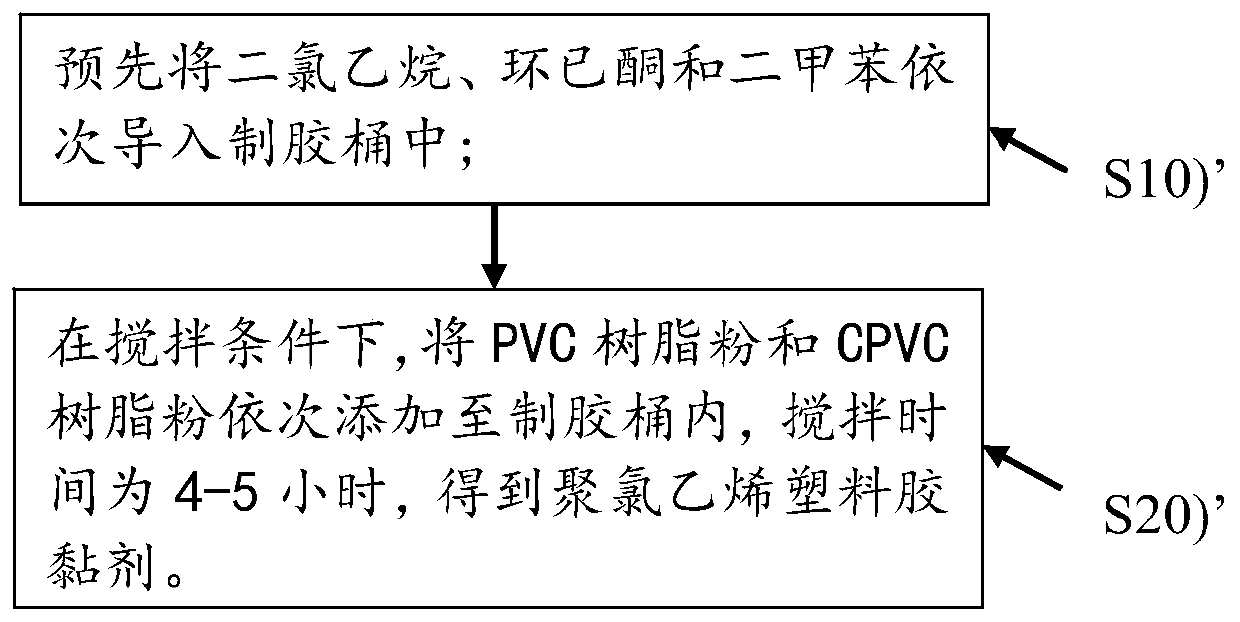

[0032] For the preparation method of the polyvinyl chloride plastic adhesive of this embodiment, please refer to figure 1 shown, including the following steps:

[0033] S10), ethylene dichloride is introduced into the rubber barrel in advance, and ethylene dichloride is used as the primary dissolving solvent of PVC resin powder and CPVC resin powder;

[0034] S20), uniformly mixing PVC resin powder and CPVC resin powder to obtain dry blended resin;

[0035] S30), under stirring conditions, add the dry blended resin into the glue barrel, and use dichloroethane to primary dissolve the dry blended resin to obtain the primary dissolved adhesive. Preferably, in this step, the stirring time is not low In 1.5 hours, more preferably, the stirring time is 1.8-2.5 hours;

[0036] S40), under stirring conditions, add cyclohexanone and xylene in the...

Embodiment 2

[0037] Embodiment 2: the remaining technical solutions of this embodiment 2 are the same as embodiment 1, and the difference is that this embodiment 2 proposes a polyvinyl chloride plastic adhesive, including the raw materials of the following parts by weight:

[0038] Recycling 15 parts of PVC plastic powder, obtained after crushing and pulverizing recycled PVC plastic;

[0039]

Embodiment 3

[0040] Embodiment 3: all the other technical solutions of this embodiment 3 are the same as embodiment 1, the difference is that this embodiment 3 proposes a polyvinyl chloride plastic adhesive, comprising the raw materials of the following parts by weight:

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com