Clutch mechanism of electric pipette

A technology of clutch mechanism and pipette, which is applied in the field of pipette, can solve the problems of motor blocking, pipette stroke adjustment failure, etc., and achieve the effect of ensuring safe work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

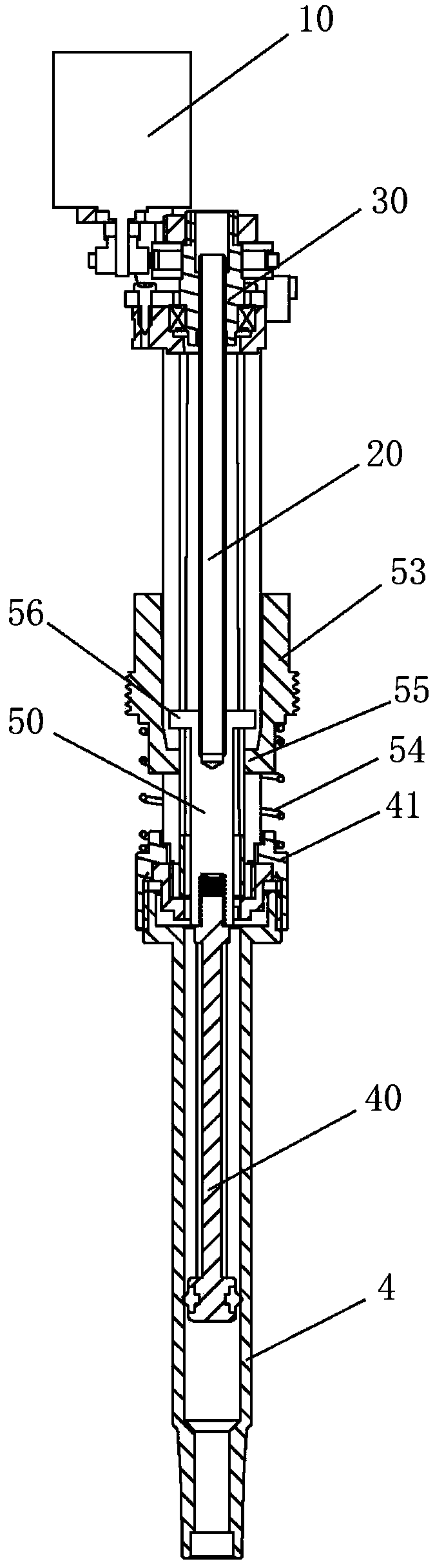

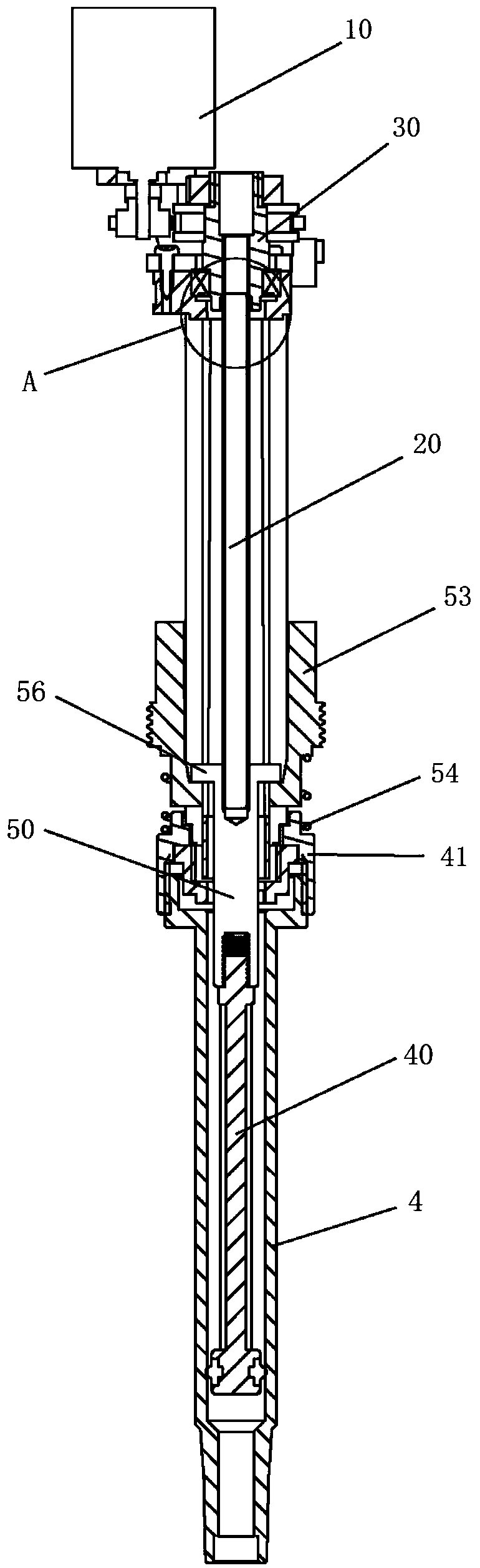

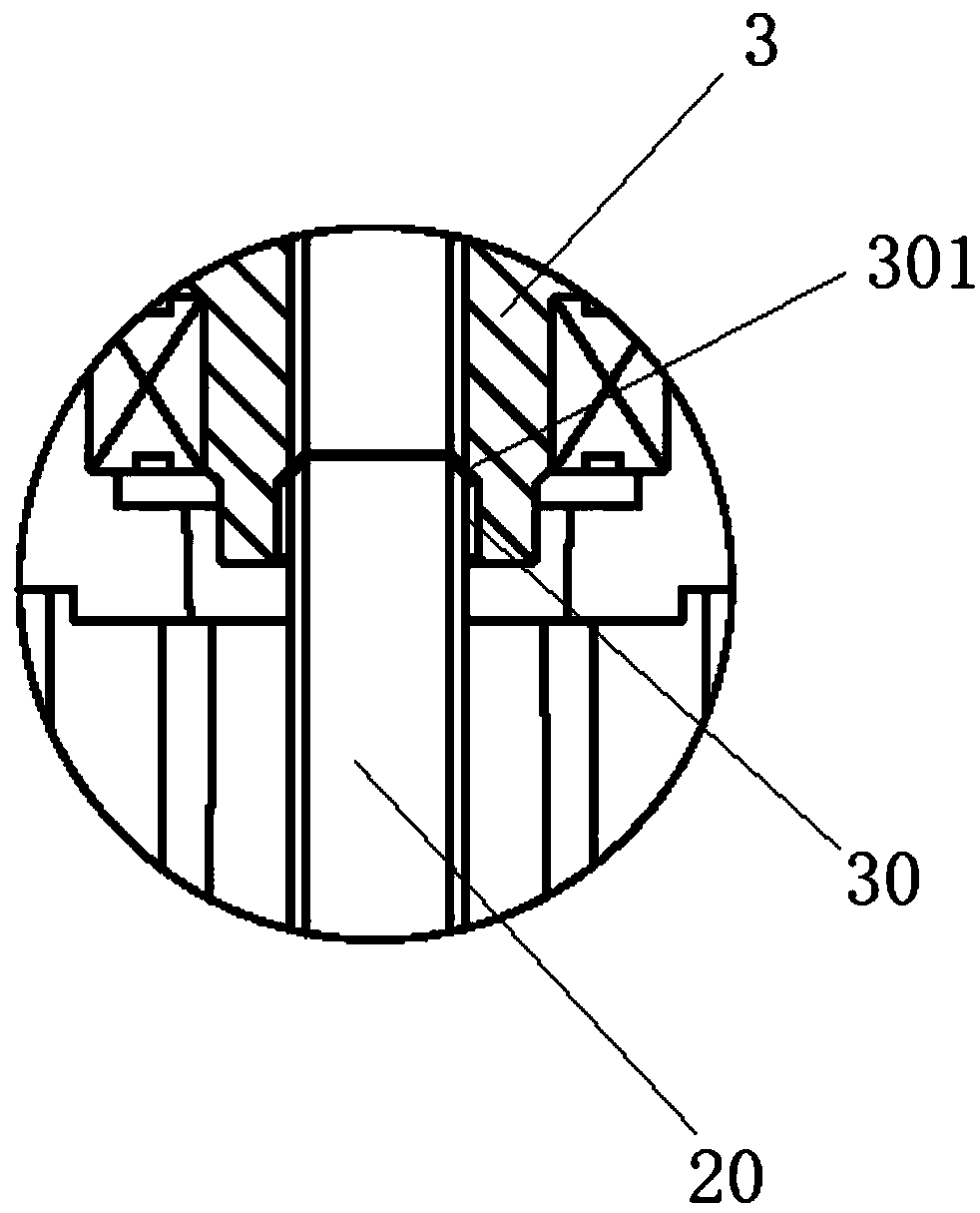

[0025] see Figure 1-5 , an electric pipette clutch mechanism, which includes a screw nut 3, a screw rod 20, a piston rod 40, the piston rod 40 is placed in the inner piston cylinder 4, and the screw nut 3 is driven by a drive motor 10 To or reverse rotation, the upper end of the screw rod 20 is connected with the internal thread of the screw nut 3, the lower end of the screw rod 20 is connected with the upper end of the piston rod 40, the lower end of the screw nut 3 The end is provided with a limit groove 30, the limit groove 30 is concentric with the internal thread of the screw nut 3, and the limit groove 30 is used to connect the external thread of the screw rod 20 with the screw rod. When the internal thread of the nut 3 is separated, the upper end of the screw rod 20 is restricted from deviating from the axis; the axial length of the screw rod 20 connected to the piston rod 40 is less than or equal to that between the bottom of the limiting groove 30 and the piston rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com