Boiler combustion efficiency online monitoring device

A boiler combustion and monitoring device technology, which is applied to measurement devices, combustion methods, exhaust gas devices, etc., can solve the problems of large maintenance, difficulty in meeting users' measurement accuracy and stability, and unsatisfactory measurement stability and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

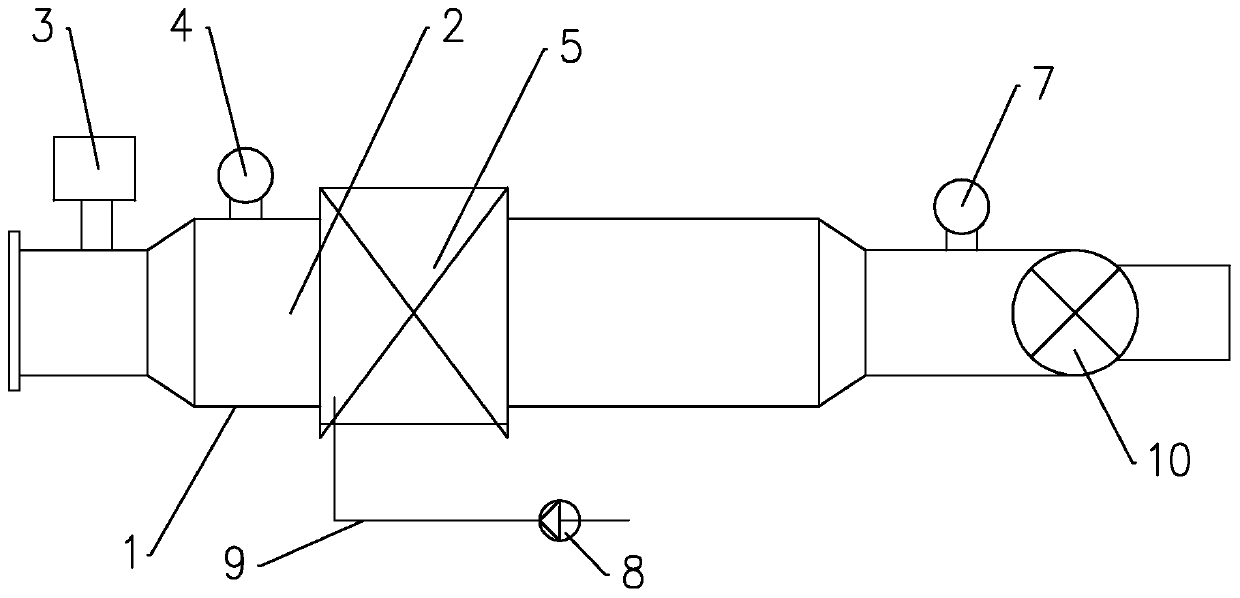

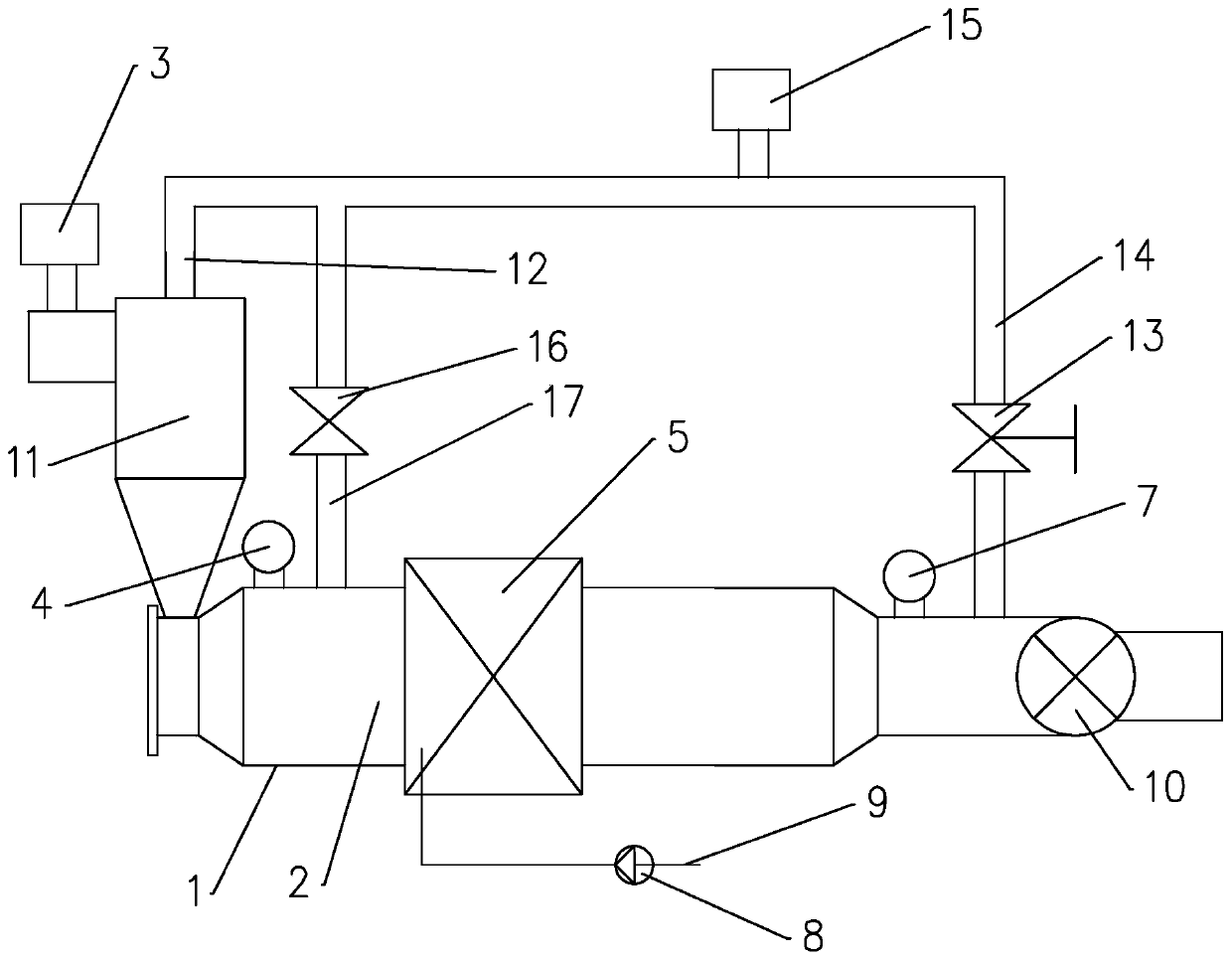

[0018] like figure 1 As shown, the boiler combustion efficiency online monitoring device of the present invention includes a casing 1, a flue gas channel 2 is arranged in the casing 1, an inlet section carbon dioxide detector 4 is arranged at the inlet section of the flue gas channel 2, A heating device 5 is provided, and the heating device 5 can heat the residual carbon in the flue gas channel 2 to a temperature above the carbon ignition point.

[0019] As a further improvement of the present invention, the above-mentioned flue gas channel 2 is provided with a flue gas flow tester 3 .

[0020] As a further improvement of the present invention, the above heating device 5 is a microwave heating device or an infrared heating device or an electric heating device or a high temperature plasma heating device or a hot air medium heating device.

[0021] As a further improvement of the present invention, the above-mentioned flue gas passage 2 is communicated with the outside atmosphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com