Optimized injection system for underground water in-situ chemical remediation agent

A technology of chemical restoration and repairing agents, applied in the restoration of contaminated soil, etc., can solve the problems of complex chemical reaction conditions, slow agent injection speed, high agent residue, etc., to improve safety, shorten injection time, and reduce repair costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

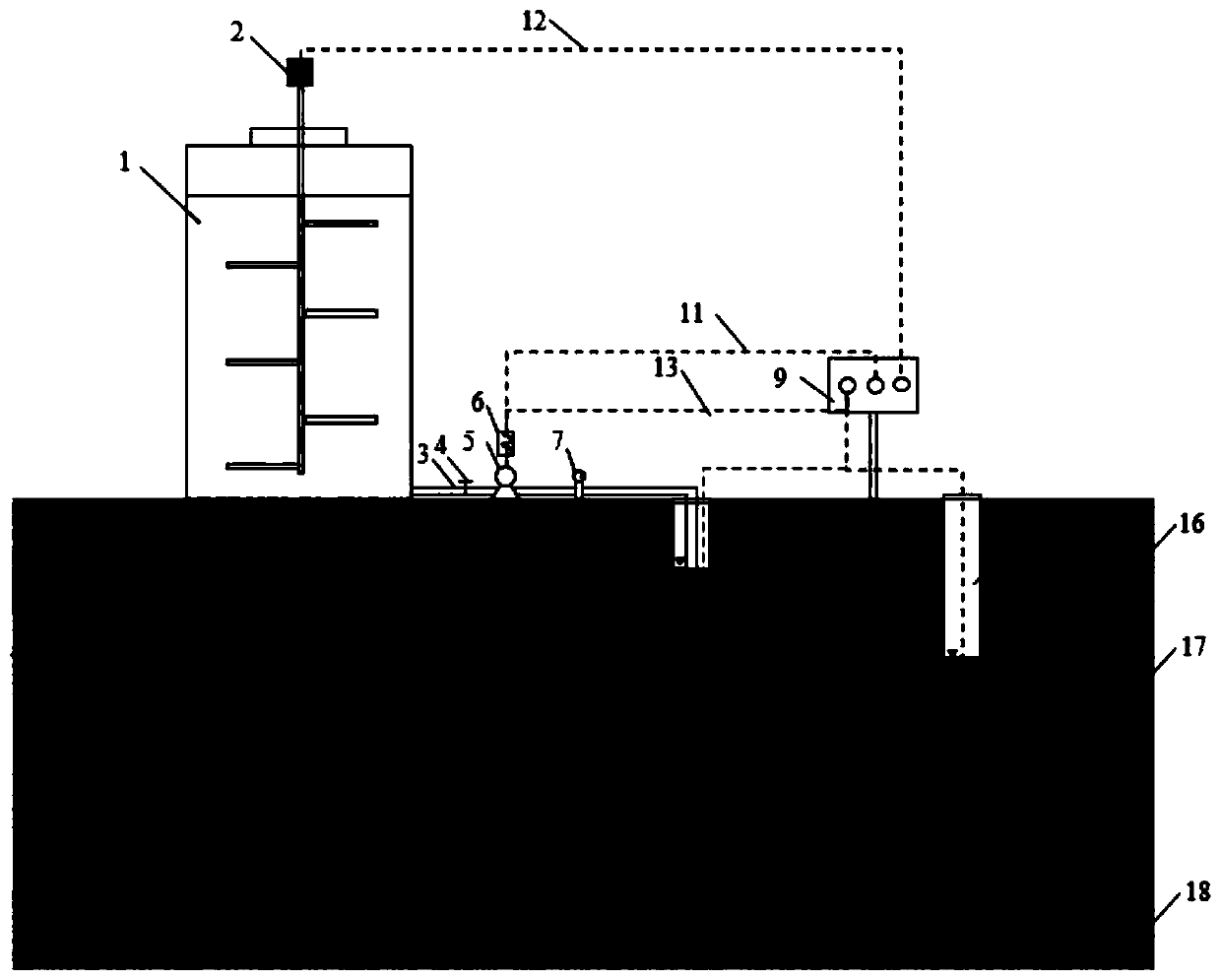

Embodiment 1

[0029] This project is a groundwater restoration project for a chemical plant in Southwest China, with a groundwater restoration area of 247,000 square meters. There are two layers of silty clay on this site, and the aquifer is a round gravel layer. The average water level is buried at a depth of 15m, and the thickness of the aquifer is 14-20m. The target pollutants in groundwater are 1,1-dichloroethane, chloroform and other organic substances. The initial value of water quality is pH 4.41, ORP is 102mV and conductivity is 32μs / cm. The restoration technology adopts the system of the present invention, and the oxidizing agent used is sodium persulfate. Add solid sodium persulfate to the injection tank, add water and turn on the agitator to make a mass concentration of 100kg / m 3 sodium persulfate solution, the stirring speed of the stirrer is 50r / min. Set the target value of the input static pressure liquid level gauge to 25m through the PLC control box, set the liquid level...

Embodiment 2

[0031]This project is a groundwater restoration project for a chemical plant in Southwest China, with a groundwater restoration area of 247,000 square meters. There are two layers of silty clay in this site, and the aquifer is a round gravel layer, with an average buried depth of 15m and an aquifer thickness of 14-20m. The target pollutants in groundwater are organic compounds such as vinyl chloride and 1,2-dichloroethane. The initial value of water quality is pH 5.71, ORP 65mV and conductivity 98.7μs / cm. The restoration technology adopts the system of the present invention, and the oxidizing agent used is sodium persulfate. Add solid sodium persulfate to the injection tank, add water and turn on the agitator to make a mass concentration of 80kg / m 3 sodium persulfate solution, the stirring speed of the stirrer is 60r / min. Set the target value of the input static pressure liquid level gauge to 24m through the PLC control box, set the liquid level in the injection well and ...

Embodiment 3

[0033] This project is a groundwater restoration project for a machinery factory site, with a restoration area of about 60 mu. The stratum of the site is miscellaneous fill and clay from top to bottom, and the aquifer is a round gravel layer. The buried depth of the water level is 4-7m, and the thickness of the aquifer is about 2-4m. The groundwater at the original site was polluted by carbon tetrachloride, vinyl chloride and chloroform. The initial value of the water quality is pH 5.77, ORP 88mV and conductivity 79.1 μs / cm. The restoration technology adopts the system of the present invention, and the oxidizing agent used is sodium persulfate. Add solid sodium persulfate to the injection tank, add water and turn on the agitator to make a mass concentration of 50kg / m 3 sodium persulfate solution, the stirring speed of the stirrer is 70r / min. Set the target value of the input static pressure liquid level gauge to 7m through the PLC control box, set the liquid level in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com