Drilling Die for Space Hole of Shaft Parts

A shaft parts and space technology, which is applied in the field of drilling dies for shaft parts space holes and special drilling dies for shaft parts, can solve the problems of large repetitive workload, affecting hole machining accuracy, and long clamping time, and saves money. The effect of manufacturing cost and management cost, reducing labor intensity, accurate and reliable processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings, so as to help those skilled in the art to have a more complete and in-depth understanding of the present invention.

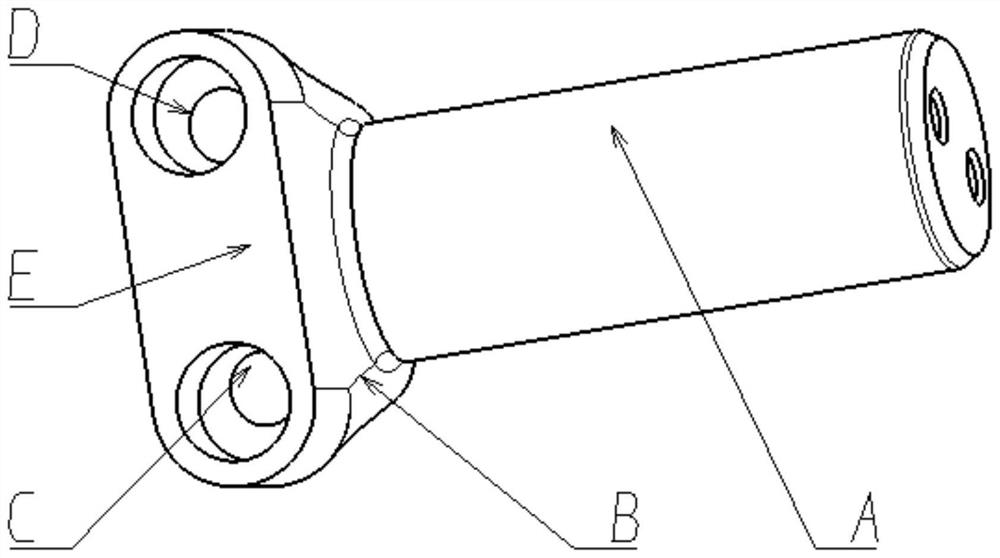

[0036] like Figure 5 As shown, a space hole drilling die for shaft parts includes a base body 1 , a positioning plate 2 , a screw rod 3 , a pressing plate 4 , a nut 5 and a drill sleeve 6 .

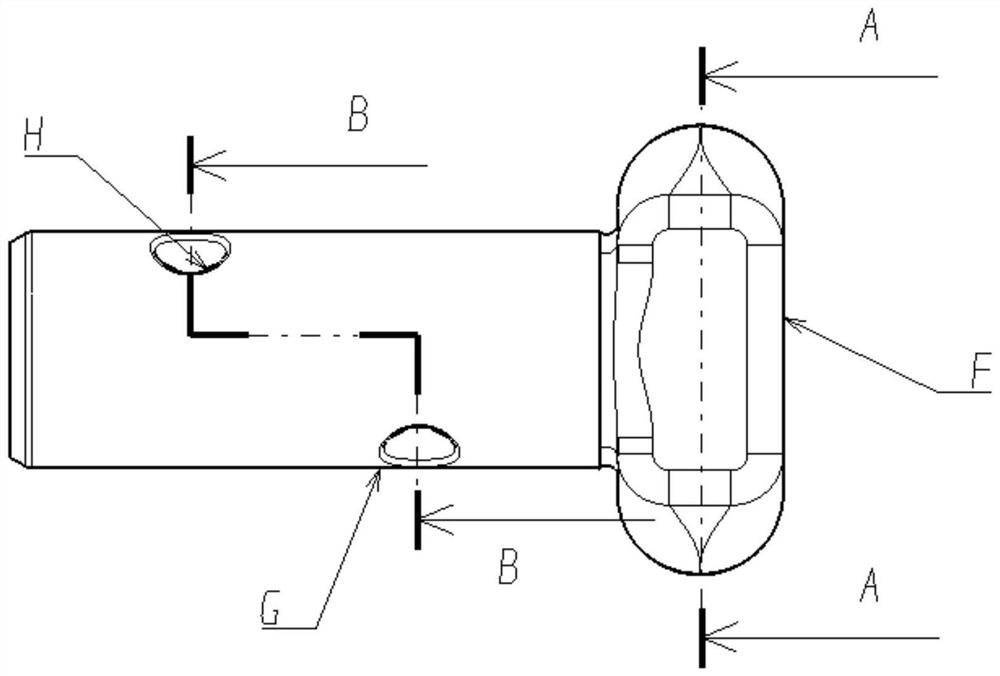

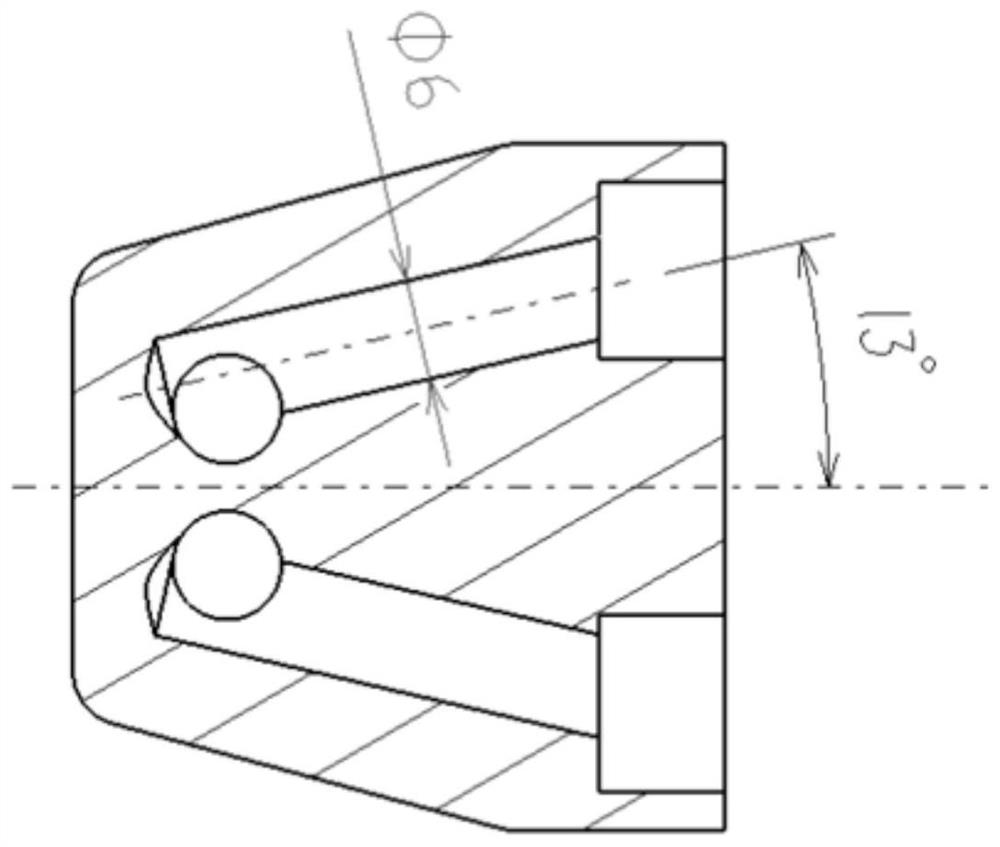

[0037] like Figure 6-Figure 8 As shown, the substrate 1 is an irregular hexagonal prism structure, and its surface G1-7 is parallel to the surface H1-17, the surface A1-1 is parallel to the surface D1-4, the surface B1-2 is parallel to the surface E1-5, and the surface C1- 3 is parallel to face F1-6. A cylindrical pin A1-10 and a chamfering pin A1-9 are provided on the surface G1-7 of the base body 1 and close to the surface A1-1, and the surface H1-17 of the base body 1 is provided at a position close to the surface A1-1. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com