Improved CPVC power tube

An improved technology for power pipes, which is applied in cable installation, cable installation in underground pipelines, coating, etc., can solve the problem that CPVC pipes cannot fully adapt to high-demand environments, and achieve excellent fire and flame retardant performance, durability Strong corrosion resistance and low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

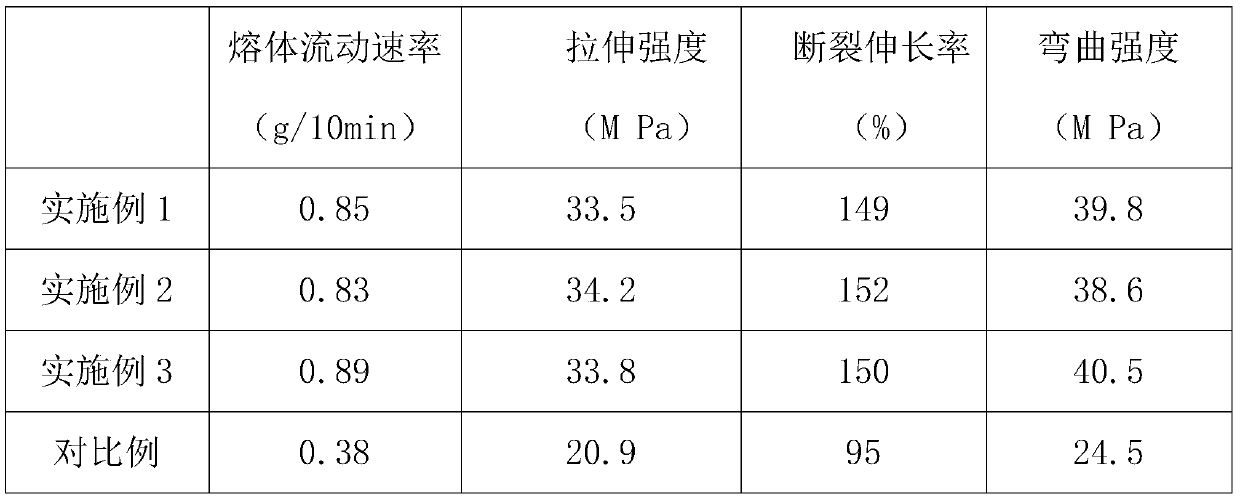

Examples

Example Embodiment

[0028] The preparation method includes the following steps:

[0029] S1: Put the modified polyvinyl chloride, graphene A, carbon black, composite lubricant, composite lubricant and titanium dioxide into a high-speed mixer according to parts by weight, and set the mixing paddle speed to 800-1000r / min. The temperature is set to 130-140°C, and the mixing time is set to 10-15min to obtain mixture one;

[0030] S2: Put the mixture one, nano calcium carbonate, antioxidant, coupling agent, toughening agent and compatibilizer into a high-speed mixer for mixing in sequence, the rotating speed of the mixing paddle is set to 900-1000r / min, and the mixing temperature is set to 90-110℃, the mixing time is set to 10-30min, to obtain the second mixture;

[0031] S3: Put the mixture 2 into a twin-screw extruder for extrusion molding to obtain a semi-finished CPVC power pipe;

[0032] S4: Take polyurethane resin, methyl methacrylate, butyl acrylate and 30-35wt% deionized water in parts by weight, add...

Example Embodiment

[0035] Example 1

[0036] An improved CPVC power pipe, including raw materials of the following weight components: 100 parts of chlorinated polyvinyl chloride, 5 parts of graphene A, 8 parts of carbon black, 6 parts of coupling agent, 12 parts of toughening agent, and 5 parts of compatibilizer Parts, 5 parts of composite lubricant, 1 part of antioxidant, 1 part of nano calcium carbonate, 0.8 part of titanium dioxide, and 5 parts of flame retardant compound.

[0037] The preparation method of the improved CPVC power pipe of this embodiment includes the following steps:

[0038] S1: Put the modified polyvinyl chloride, graphene A, carbon black, composite lubricant, composite lubricant and titanium dioxide into a high-speed mixer according to parts by weight for mixing, the mixing paddle speed is set to 900r / min, and the mixing temperature is set Set the temperature to 130°C and the mixing time to 13min to obtain mixture one;

[0039] S2: Put the mixture one, nano calcium carbonate, ant...

Example Embodiment

[0043] Example 2

[0044] An improved CPVC power pipe, including raw materials of the following weight components: 110 parts of chlorinated polyvinyl chloride, 6 parts of graphene A, 9 parts of carbon black, 7 parts of coupling agent, 12 parts of toughening agent, 4 parts of compatibilizer Parts, 5 parts of composite lubricant, 1.5 parts of antioxidant, 1 part of nano calcium carbonate, 1 part of titanium dioxide, and 8 parts of flame retardant composite material.

[0045] The preparation method of the improved CPVC power pipe of this embodiment includes the following steps:

[0046] S1: Put the modified polyvinyl chloride, graphene A, carbon black, composite lubricant, composite lubricant and titanium dioxide into a high-speed mixer according to parts by weight for mixing, the mixing paddle speed is set to 900r / min, and the mixing temperature is set Set the temperature to 130°C and the mixing time to 13min to obtain mixture one;

[0047] S2: Put the mixture one, nano calcium carbona...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap