Airtight connection device and method for vertical flexible anti-seepage wall

The technology of a connecting device and a connecting method, which is applied in the field of environmental treatment of polluted sites, can solve problems such as affecting the effect of sealing connection of anti-seepage walls and being prone to conflict with each other, and achieves the effect of simple structure, favorable construction, and prevention of side wall collapse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

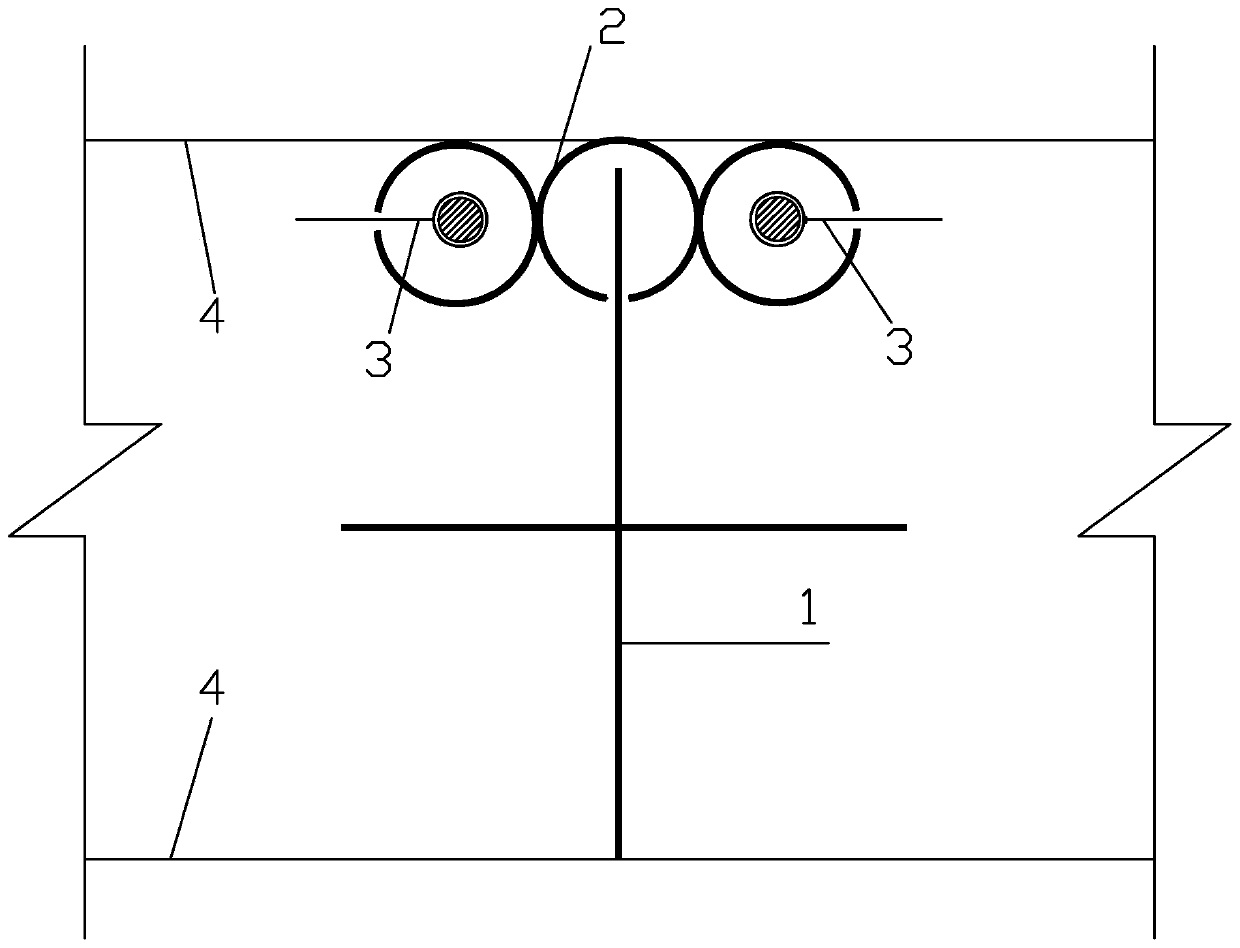

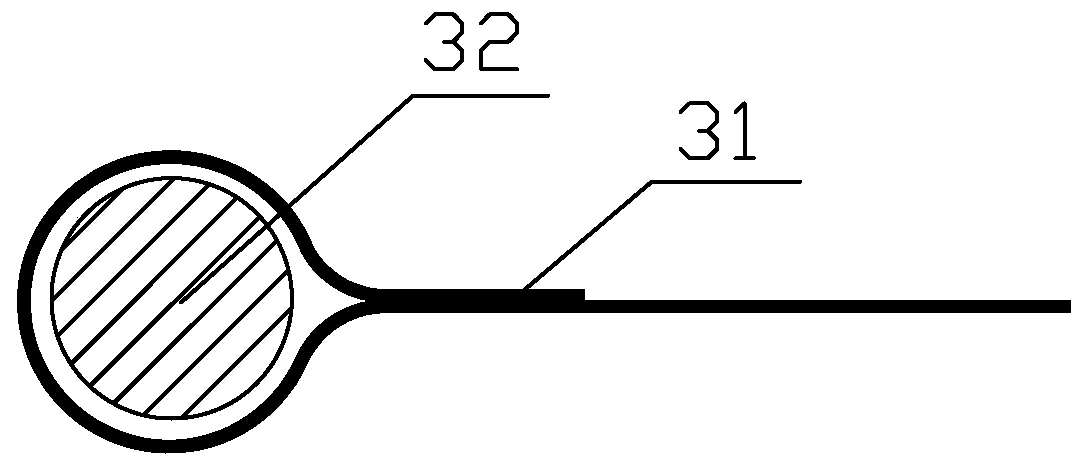

[0034] Such as figure 1 , figure 2 , image 3 As shown, the present invention provides a kind of airtight connection device of vertical flexible cut-off wall, which is used for the connection of two adjacent flexible membranes in the groove. For convenience, the horizontal extension direction of the groove is called horizontal direction, and the groove width direction is called longitudinal , the airtight connection device includes a three-link bearing structure 2, a cross support joint 1 and a flexible membrane insertion structure 3, wherein:

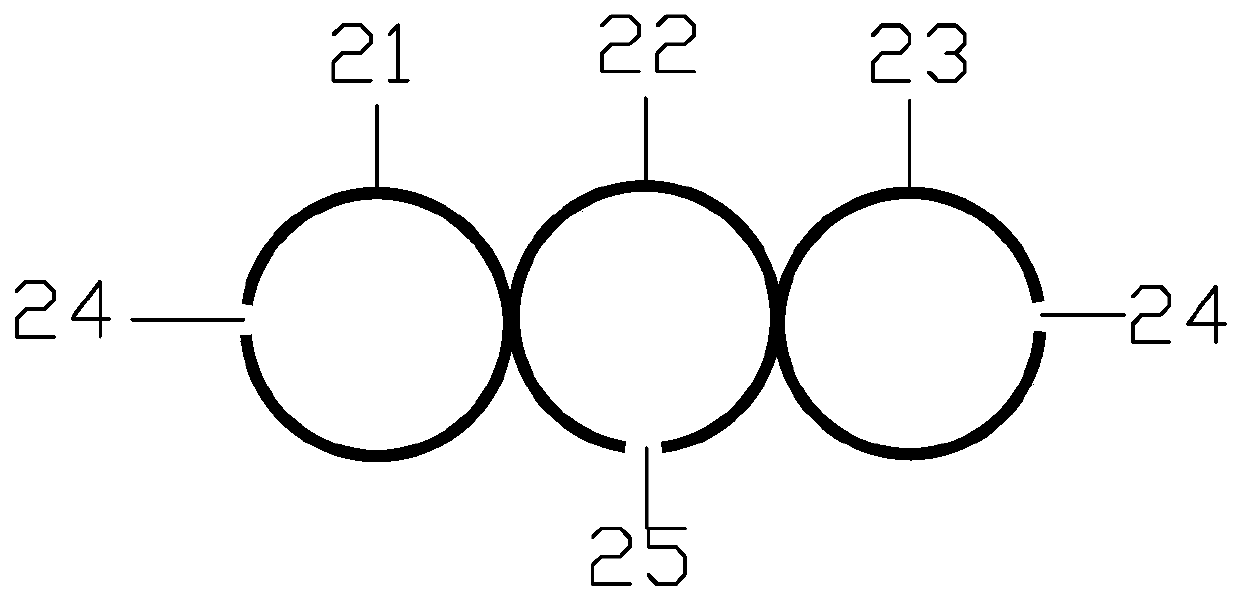

[0035] The three-link supporting structure 2 is composed of three connecting rings 21, 22, and 23 with gaps that are integrally connected in the horizontal direction. The three connecting rings 21, 22, and 23 have the same size, and the material is preferably HDPE material. Each connecting ring The outer diameters of 21, 22, and 23 are about 90 mm, and the thickness is about 8.2 mm; the connecting rings 21 and 23 on both sides have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com