Spinning type tracking reflecting light condensing device

A concentrating device and spin-type technology, which is applied in the direction of solar ray concentration, solar collector controller, lighting and heating equipment, etc., can solve the problem of light energy waste and achieve the effect of improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

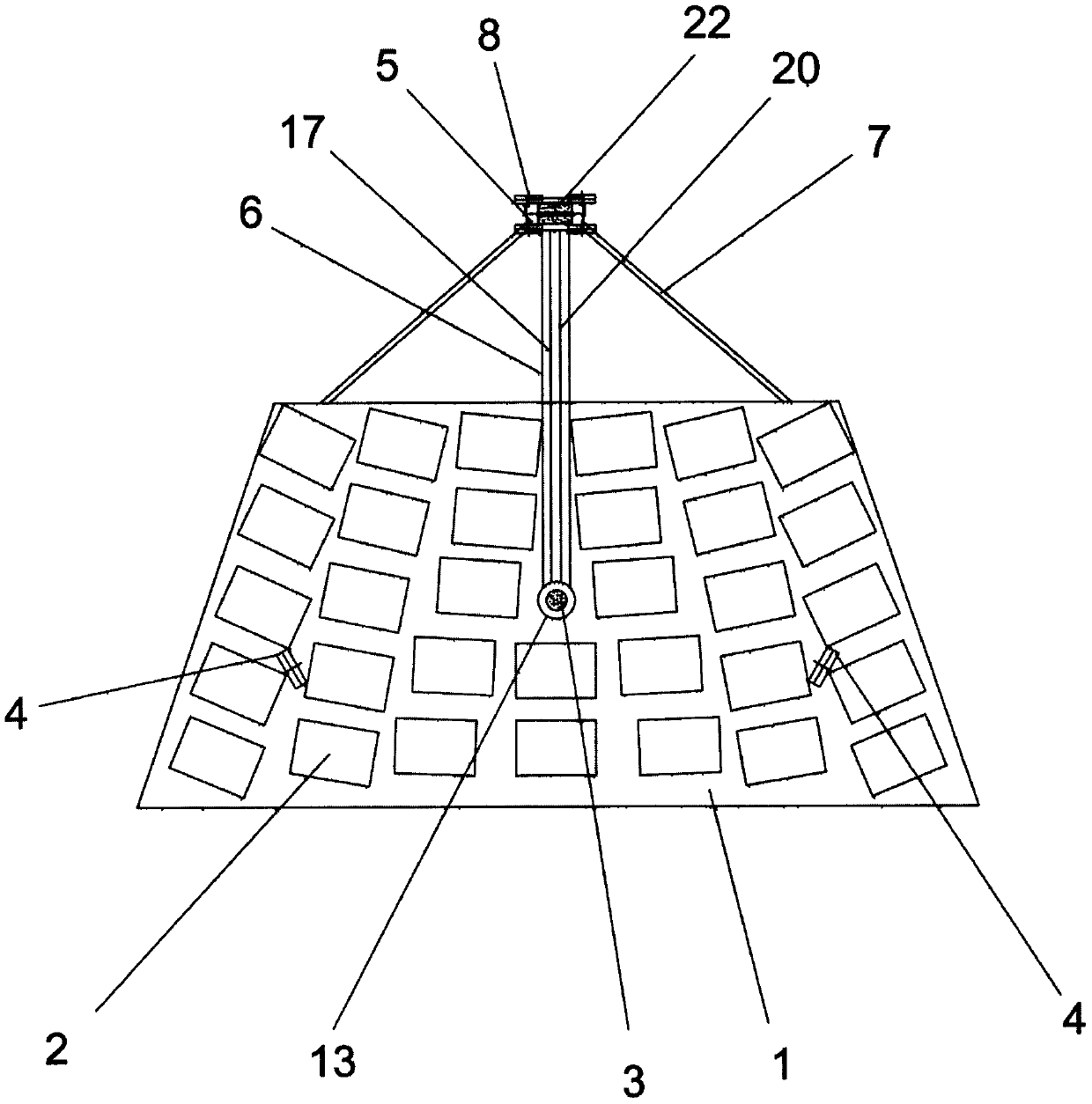

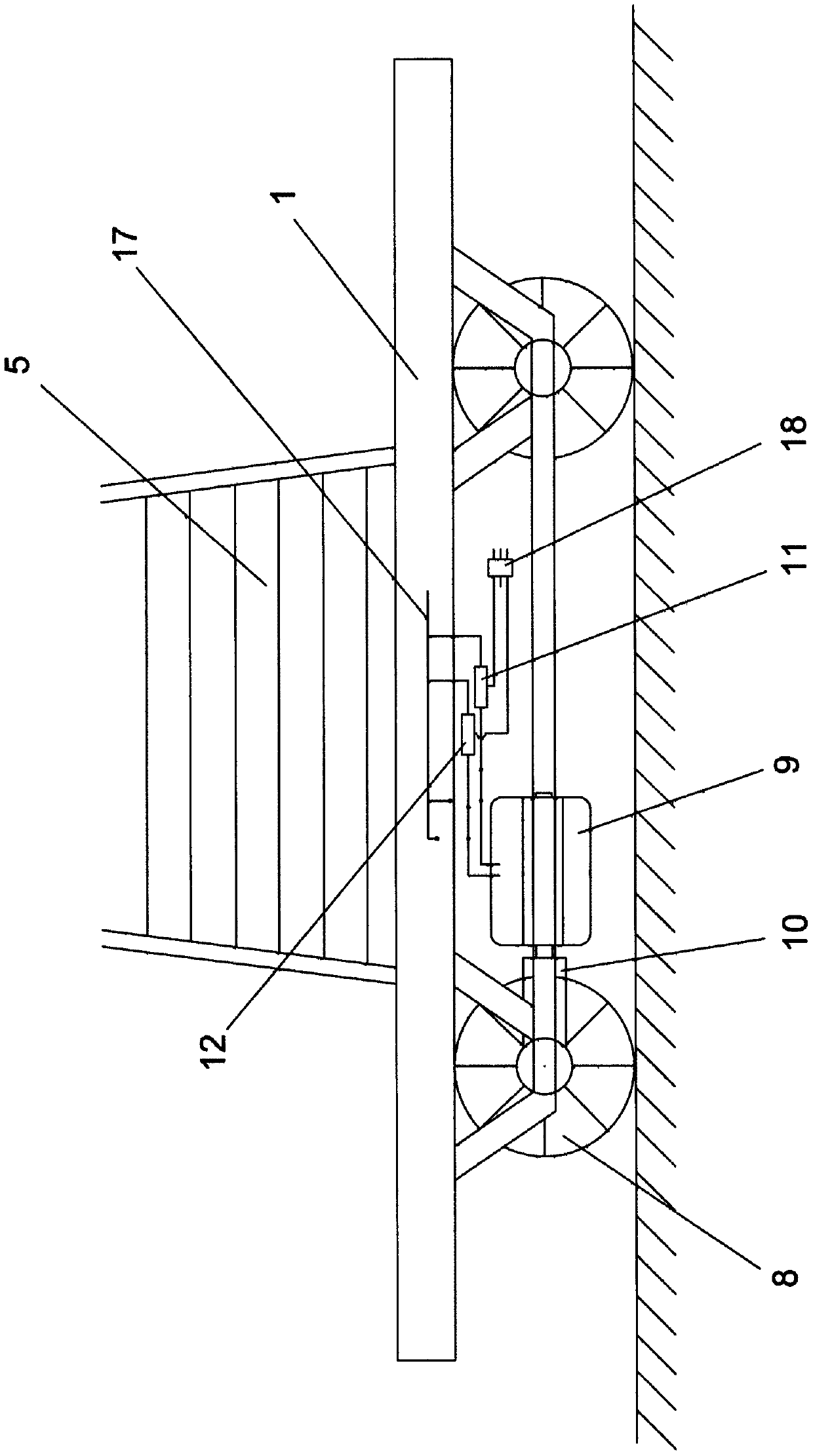

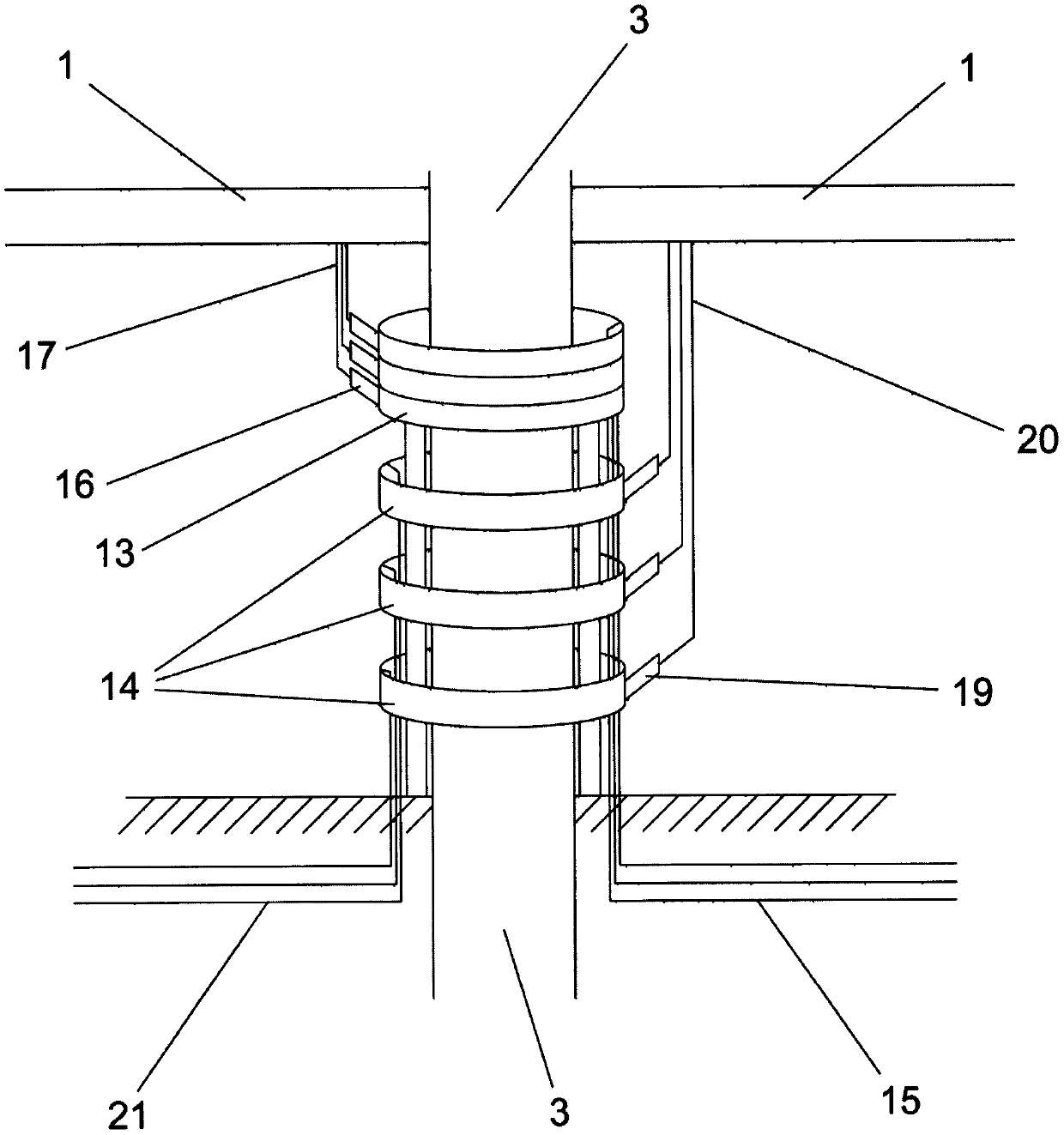

[0021] The spin-type tracking reflective concentrating device includes a horizontal frame 1, on which a plurality of reflectors are installed to form a reflector array 2, and the bottom of the horizontal frame 1 has a rotating shaft 3, which is perpendicular to the ground and extends into the ground below. Two load-bearing wheels 4 are installed at the bottom of the horizontal frame 1, and the load-bearing wheels 4 are in contact with the ground. Another concentrating tower 5 is rigidly connected with the horizontal frame 1 through the connecting arm 6, and a triangular support arm 7 is respectively arranged on both sides of the connecting arm 6, and the triangular support arm 7 is connected with the horizontal frame 1 and the concentrating tower 5 to play the role of Fixed the effect of Focus Tower 5. Such as figure 2 , four load-bearing driving wheels 8 are installed below the focusing tower 5, and each bearing driving wheel 8 bears the weight of the focusing tower 5 and ...

Embodiment 2

[0034] Such as Figure 8 , the rotating shaft 3 can be arranged at the bottom of the horizontal frame 1 or at the bottom of the connecting arm 6 . Compared with being arranged at the bottom of the horizontal frame 1, the rotation axis 3 is arranged at the bottom of the connecting arm 6, which can reduce the rotation radius of the focusing tower 5 and the horizontal frame 1 around the rotation axis 3, and occupy a smaller site area.

Embodiment 3

[0036] The concentrating tower 5 can directly contact the ground through the load-bearing driving wheel 8, and also can lay a circular track on the ground, and the load-bearing driving wheel 8 is placed on the circular track. The ring track takes the rotating shaft 3 as the center and the distance from the rotating shaft 3 to the load-bearing driving wheel 8 as the radius, so that the focusing tower 5 rotates on the track around the rotating shaft 3 . Compared with the load-bearing drive wheel 8 in direct contact with the ground, the annular track can provide the load-bearing drive wheel 8 with less rolling friction resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com