Vertical buried pipe heat exchanger for preventing roadbed frost heave

A buried tube heat exchanger, vertical technology, applied in indirect heat exchangers, geothermal collectors, geothermal energy and other directions, can solve the problems of poor heat exchange effect, etc. The effect of heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

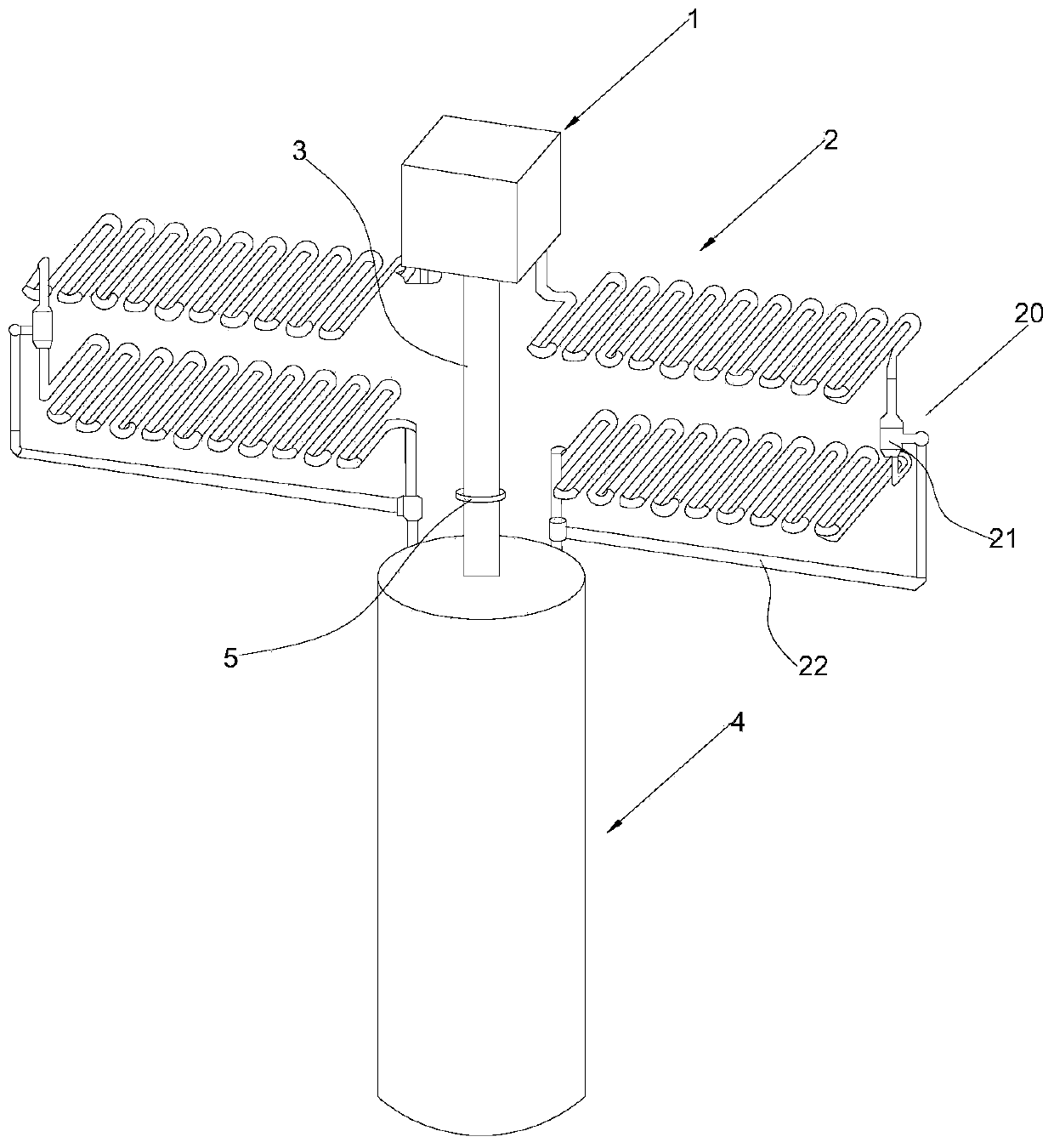

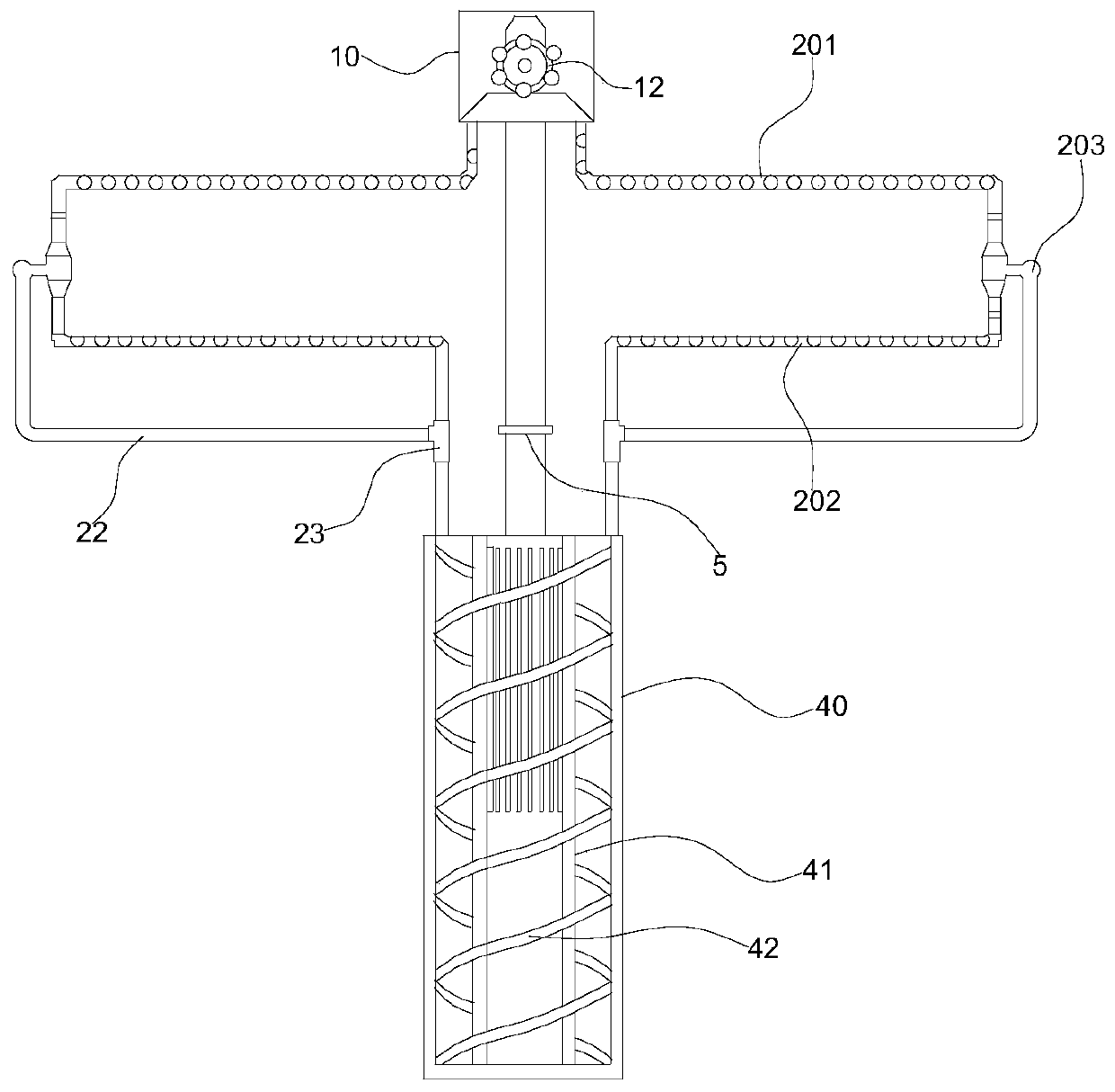

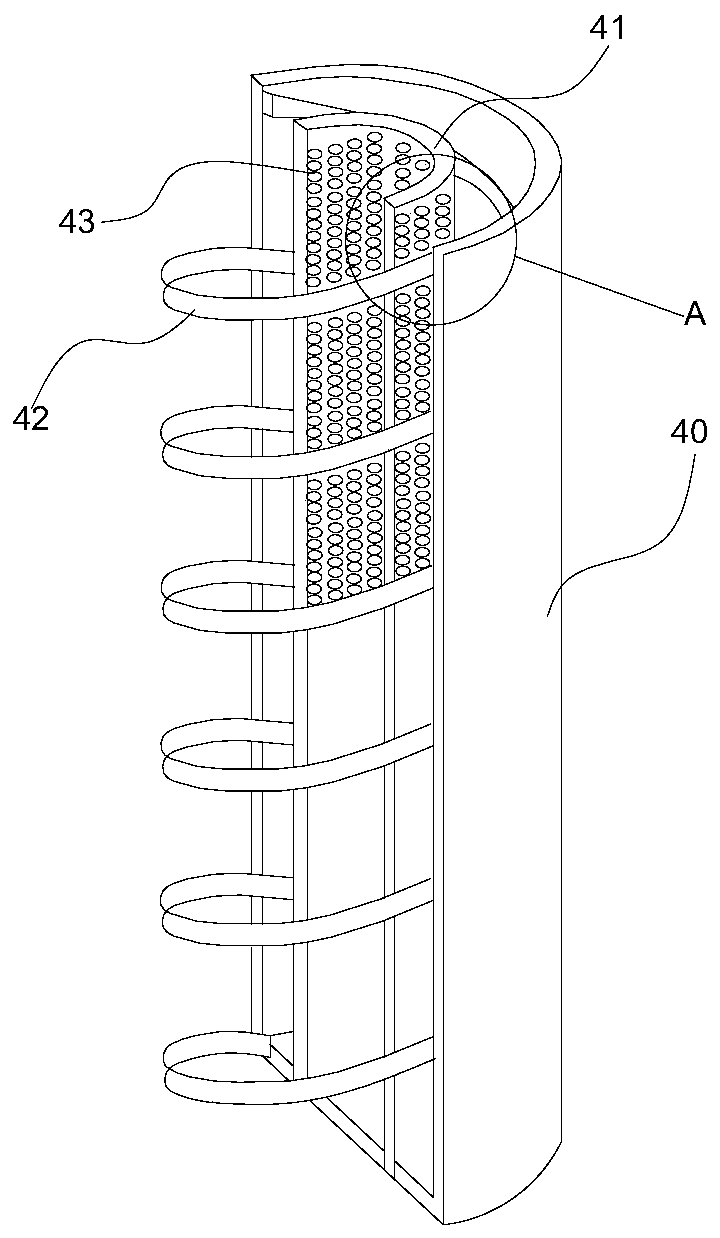

[0034] Such as Figure 1 to Figure 2 As shown, a vertical buried tube heat exchanger used to prevent frost heave of the subgrade, including a heating mechanism 1, a heat release assembly 2 connected to both ends of the heating mechanism 1, and a heating pipe 3 connected to the heating The cooling heat exchange mechanism 4 at the lower end of the mechanism 1 and communicated with the heat radiation assembly 2; The gas-liquid separator 21 and the branch pipe 22 connected between the gas-liquid separator 21 and the refrigeration heat exchange mechanism 4 .

[0035] The heat exchanger has a simple structure and is an assembled structure as a whole, which is convenient for transportation and construction needs, and has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com