Cold water air conditioner and cooling water unit and cooling water control method thereof

A control method and cooling water technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as reduced lubricating oil return efficiency, reduced cooling effect, unit shutdown, etc., to prolong service life and avoid excessive Cooling and ensuring the effect of normal oil return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

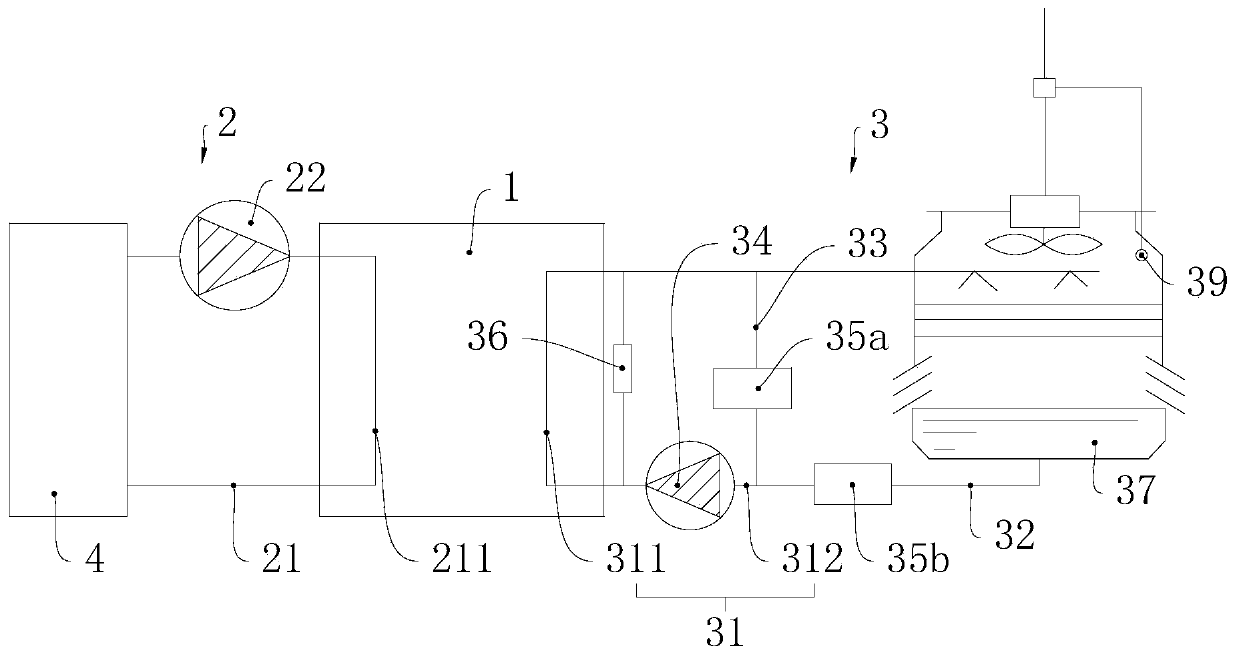

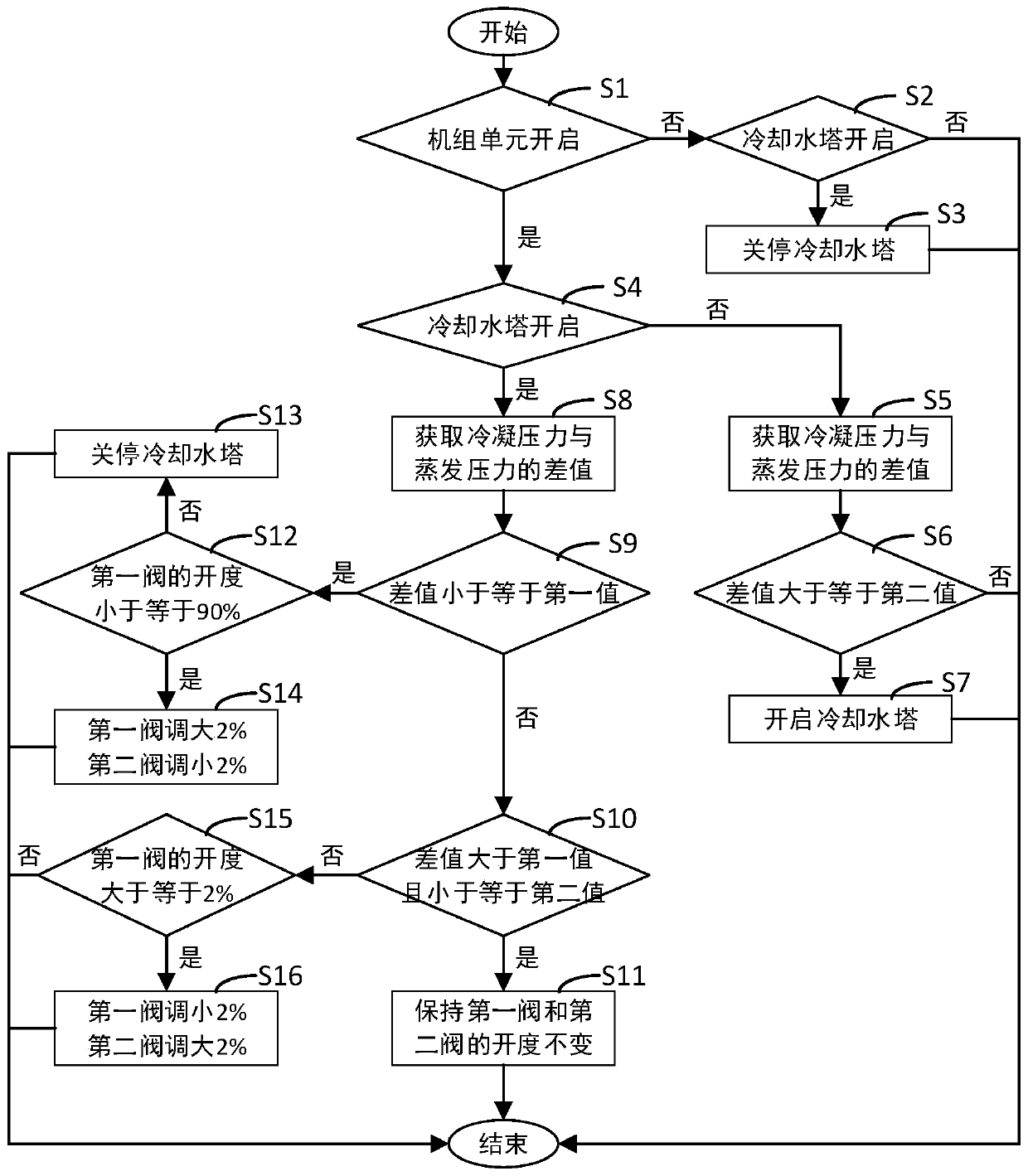

[0031] Please refer to figure 1 The cold water air conditioner of this embodiment includes a unit 1, a chilled water unit 2 and a cooling water unit 3 of this embodiment, and the unit unit 1 includes an evaporator (not shown in the figure) and a condenser (not shown in the figure).

[0032] The chilled water air conditioner of this embodiment is used for constant temperature cooling of the data room. The chilled water unit 2 includes a chilled water circuit 21 and a chilled water pump 22. The chilled water pump 22 drives the flow of chilled water in the chilled water circuit 21. The chilled water circuit 21 includes a first The heat exchange section 211 and the second heat exchange section (not shown in the figure), the first heat exchange section 211 exchanges heat with the evaporator, the second heat exchange section is arranged in the data room 4, the second heat exchange section and the data room The ambient air in 4 is heat exchanged, and the cooling capacity of the evapo...

Embodiment 2

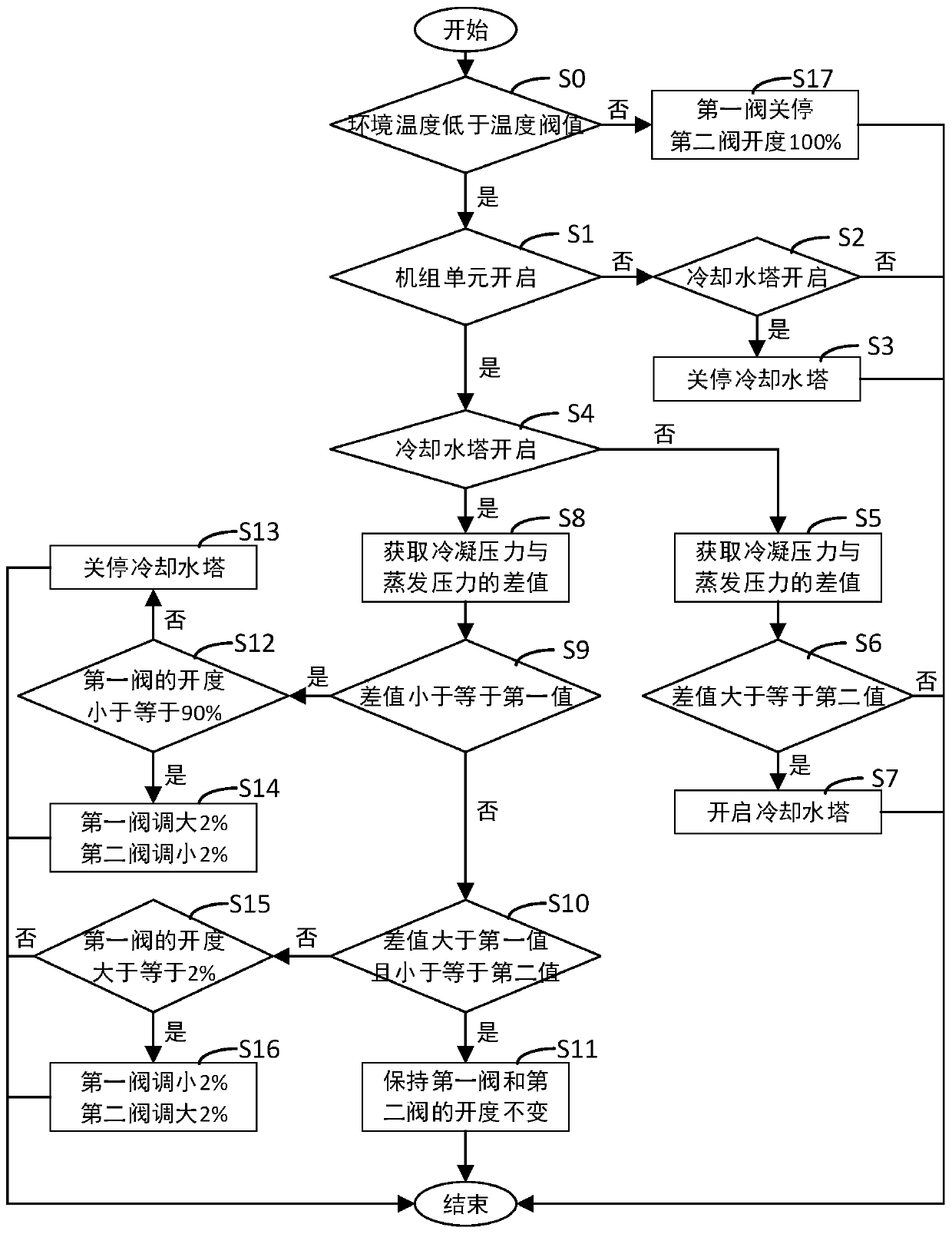

[0054] Please refer to Figure 4 , this embodiment cancels the first valve 35a, the second valve 35b and the first water pump 34 in the first embodiment, and the second water pump 38 is set on the cold water cooling pipeline 32, and the third valve 35c is set on the regulating pipeline 33 , the fourth valve 35d is set on the connecting pipeline.

[0055] By adjusting the opening of the third valve 35c and the fourth valve 35d, the cooling water flow rate of the unit cooling pipeline 31 is controlled, and then the cooling rate of the condenser by the unit cooling pipeline 31 is accelerated or slowed down.

[0056] When the difference between the condensing pressure and the evaporating pressure is lower than the desired pressure difference range, the opening of the third valve 35c is increased, and the opening of the fourth valve 35d is decreased to reduce the pressure in the cooling pipeline 31 of the unit. The cooling water flow rate reduces the cooling capacity of the unit’s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com