Quick turning method for photoelectric equipment by combining bang-bang control and overshoot-free predictive control

A technology of predictive control and optoelectronic equipment, applied in the control of using feedback, exploration of optical devices, etc., can solve problems such as system instability, and achieve the effects of strong anti-interference ability, improved rapidity, and simple control structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

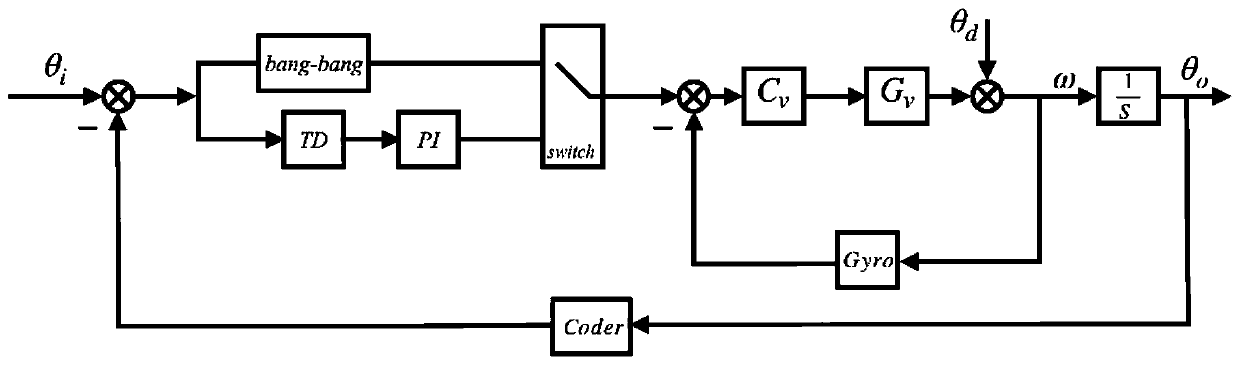

[0024] Such as figure 1 Shown is a block diagram of a method for fast switching of photoelectric equipment combining bang-bang control and non-overshoot predictive control according to the present invention. Wherein comprise encoder position loop, gyro speed loop, bang-bang controller, no overshoot controller; Adopt described device to realize the specific implementation steps of fast transfer control method as follows:

[0025] Step (1): Obtain the velocity object model G of the platform through the frequency response tester v (s). The torque motor used in the present invention has good linearity, wide speed regulation range, strong quick response ability, strong stability and high tracking accuracy at low speed, and the parameter model of the system can be obtained according to the physical mechanism modeling, and then throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com