Composite cooling fin, preparation method thereof and electronic equipment terminal

A composite heat sink and heat radiation technology, which is applied in the direction of modification through conduction heat transfer, cooling/ventilation/heating modification, modification with liquid cooling, etc., can solve the problems of electronic equipment pollution, brittleness, etc., and achieve delay Effect of temperature rise, mitigation of temperature rise, and enhanced heat dissipation mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

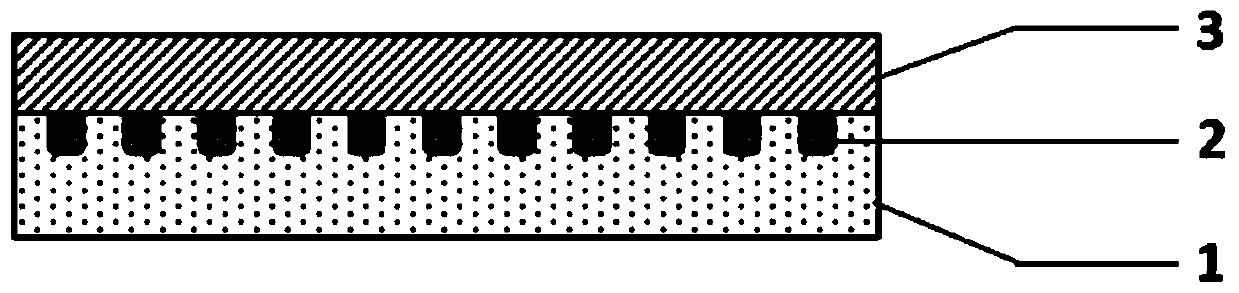

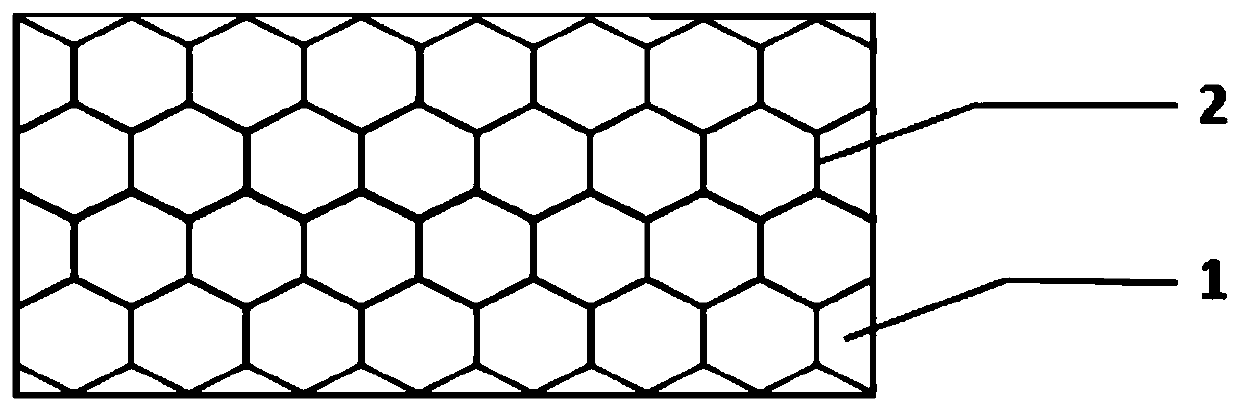

[0031] see Figure 1-2 , this embodiment discloses a composite heat sink, including a nano-metal foil 1, a phase-change heat storage function layer 2 and a heat radiation layer 3 stacked sequentially from bottom to top, wherein the nano-metal foil 1 is provided with patterned grooves , the phase change heat storage functional layer 2 is formed by filling the phase change heat storage slurry in the patterned groove and curing, and its phase change temperature is 20-100°C; the heat radiation layer 3 is formed by The heat radiation paste is coated on the phase change heat storage functional layer and cured. In this embodiment, the nano-metal foil 1 is a metal copper foil, and the patterned grooves on the metal copper foil are continuous and regularly distributed hexagonal honeycomb grooves. The thickness of the nano metal foil 1 is 70um, the thickness of the phase change heat storage functional layer 2 is 30um, and the thickness of the heat radiation layer 3 is 15um.

[0032] I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com