Steel alloy powder

A technology of alloy steel powder and iron-based alloy, which is applied in the field of alloy steel powder, can solve the problems of not being able to reduce the total cost and increase the manufacturing cost of parts, and achieve the effect of excellent fluidity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

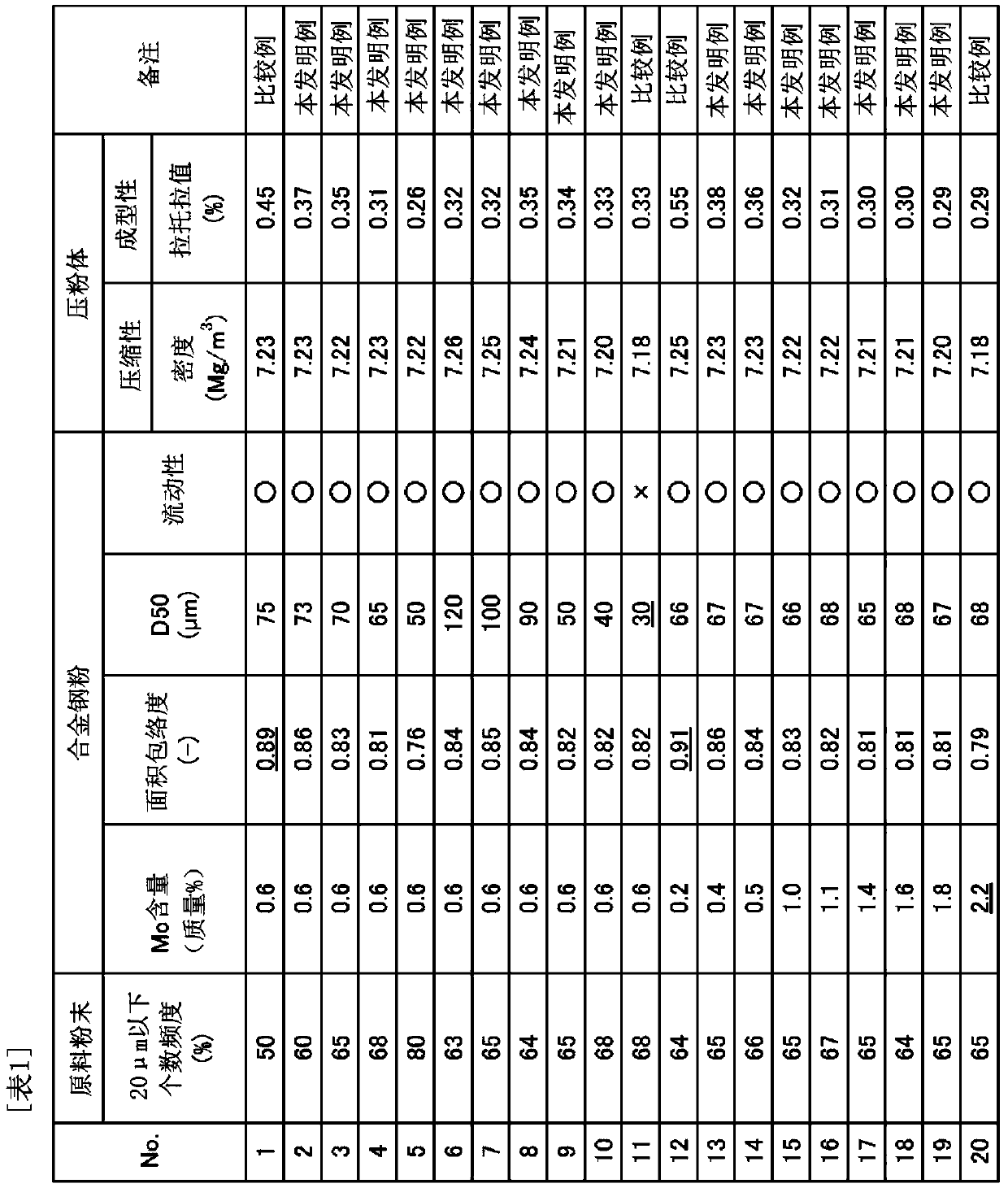

[0082] A raw material powder whose component composition and particle size distribution are adjusted is manufactured, and then the raw material powder is heat-treated to manufacture an alloy steel powder. Hereinafter, a specific procedure will be described.

[0083] First, iron-based powders having different component compositions and particle size distributions were produced by a water atomization method as the above-mentioned raw material powders. Table 1 shows the Mo content of the above raw material powder. It should be noted that the Mo content of the raw material powder is equal to the Mo content of the finally obtained alloy steel powder. In addition, the remainder other than Mo is Fe and unavoidable impurities. The above-mentioned raw material powder does not contain Ni, Cr, and Si except for unavoidable impurities, so the contents of Ni, Cr, and Si are each 0.1% by mass or less.

[0084]Table 1 collectively shows the frequency of the number of particles having a pa...

Embodiment 2

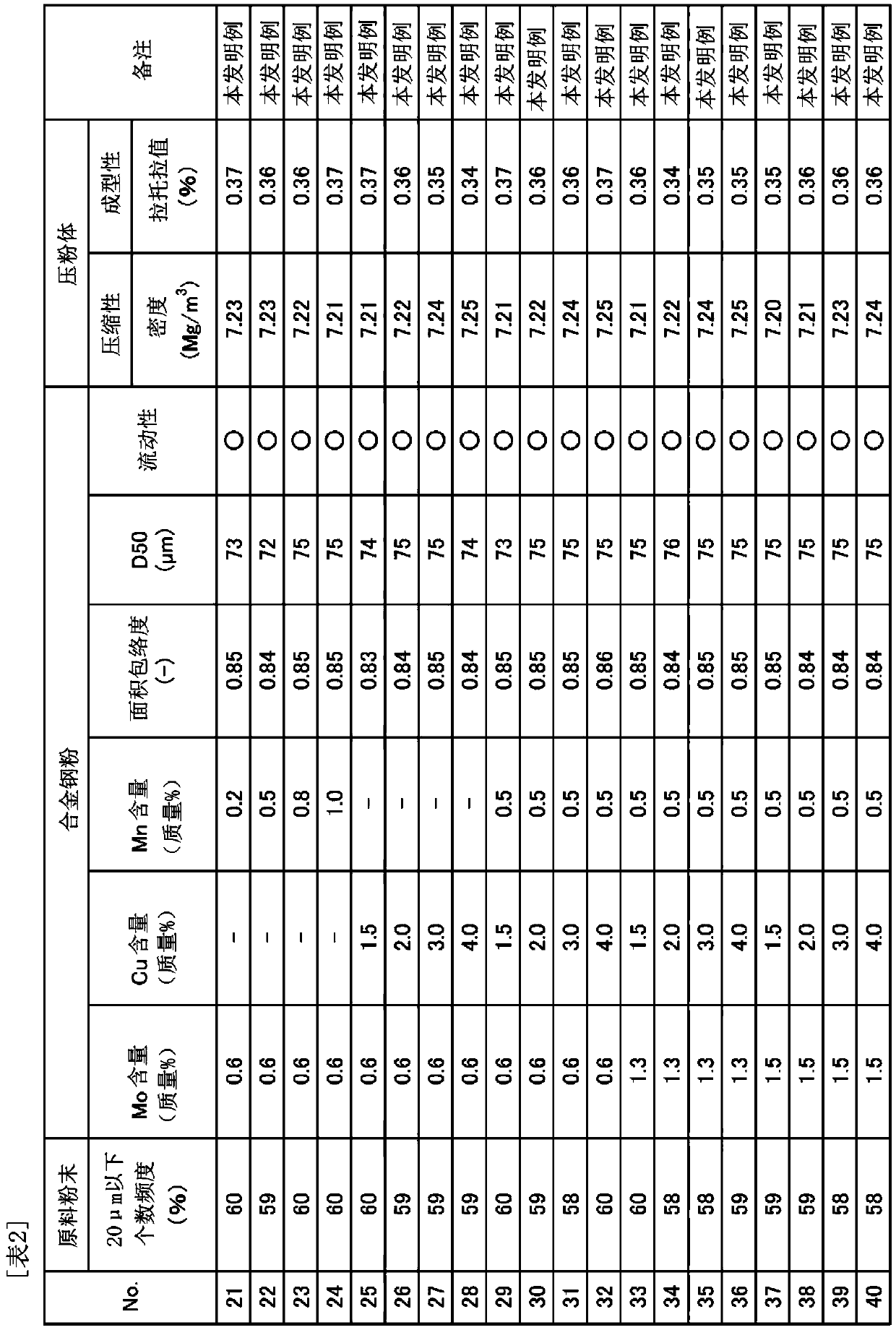

[0093] As the above-mentioned raw material powder, an iron-based powder (pre-alloyed steel powder) that further contains one or both of Cu and Mn in addition to Mo, and the remainder is composed of Fe and unavoidable impurities is used. Example 1 identical conditions to manufacture alloy steel powder. The above-mentioned iron-based powder is an atomized iron-based powder produced by an atomization method.

[0094] Table 2 shows the number frequency of particles having a particle size of 20 μm or less contained in the iron-based powder used. The said number frequency was measured by the same method as Example 1.

[0095] Next, the above-mentioned raw material powder was heat-treated under the same conditions as in Example 1 to obtain alloy steel powder. The amounts of Mo, Cu, and Mn contained in the above-mentioned alloy steel powders are the same as those of the raw material powders used, as shown in Table 2.

[0096] Image analysis was performed on each of the obtained all...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap