Composite laminate and method for producing same

A composite lamination and manufacturing method technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve problems such as heat transfer obstruction, excessive temperature increase, and inability to stably manufacture FRTP parts, and achieve Excellent releasability and excellent surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 5 and comparative example 1~ comparative example 5

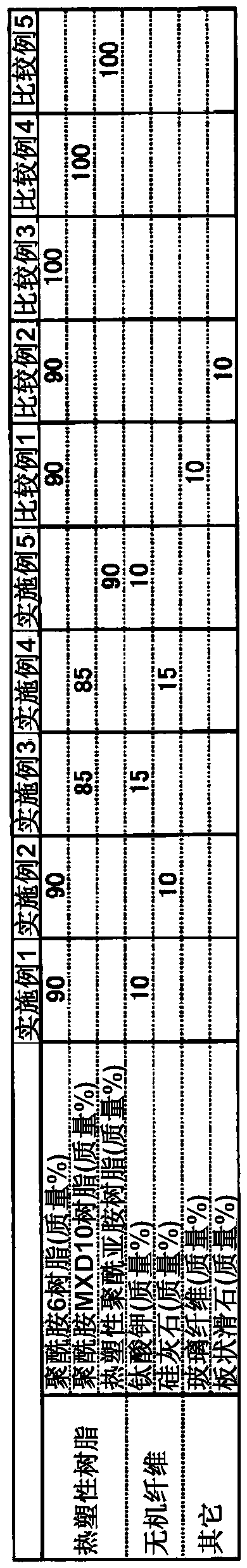

[0125] The blending ratios shown in Table 1 were melt-kneaded by a twin-screw extruder to produce pellets. In addition, the barrel temperature of the twin-screw extruder is 230°C for Examples 1 to 2 and Comparative Examples 1 to 3, 240°C for Example 3, Example 4 and Comparative Example 4, and 240°C for Examples 5 and 3. In Comparative Example 5, it was 350°C.

[0126]After drying the obtained pellets, using a film extruder (manufactured by Toyo Seiki Co., Ltd., connecting single-screw extruder D2020 (L / D=20) to LABOPLASTOMILL 4C150-01), Example 1 to Example 2 and comparative example 1~comparative example 3 with barrel temperature 230 ℃, embodiment 3, embodiment 4 and comparative example 4 with barrel temperature 240 ℃, embodiment 5 and comparative example 5 with barrel temperature 350 ℃, will from The molten resin extruded from the T-die (150 mm in width and 0.2 mm in thickness) was uniaxially stretched so that the film had a target thickness through a film pulling device, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com