A method for making a lithographic printing plate

A technology of lithographic printing and printing plate, which is applied in the direction of photo-plate-making process of pattern surface, photo-plate-making process exposure device, micro-lithography exposure equipment, etc., which can solve the problems of low efficiency, time-consuming and labor-intensive production process of printing plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

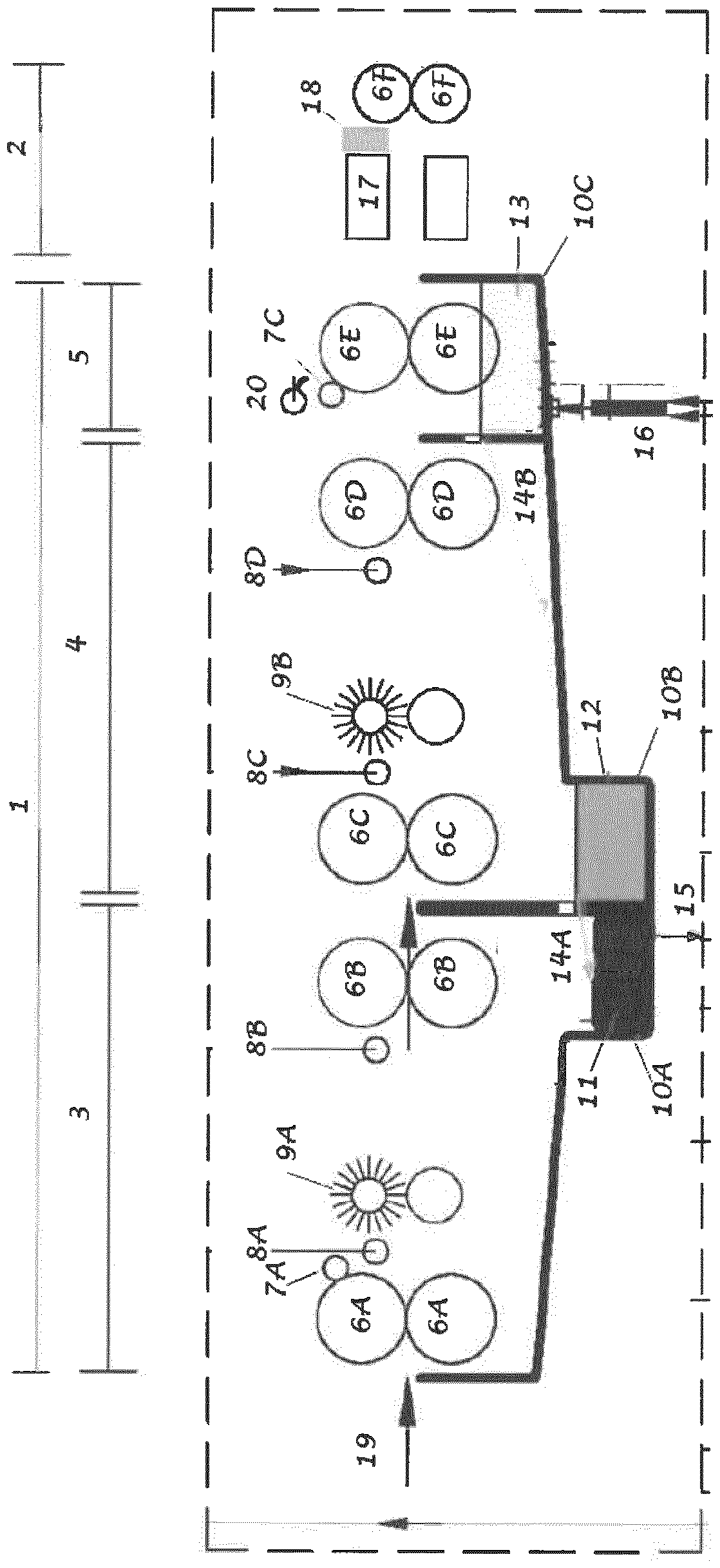

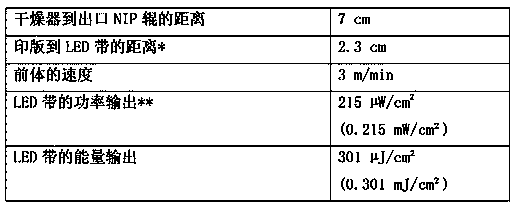

Method used

Image

Examples

Embodiment

[0139] All materials used in the following examples were readily purchased from standard sources such as Sigma-Aldrich (Belgium) and Acros (Belgium) unless otherwise indicated.

[0140] Preparation of aluminum carrier S-01

[0141] Aluminum foils of 0.3 mm thickness were degreased by spraying with an aqueous solution containing 26 g / l NaOH for 2 s at 65 °C and rinsed with demineralized water for 1.5 s. Then at a temperature of 37°C and about 100 A / dm 2 At a current density of 15 g / l HCl, 15 g / l SO 4 2- ions and 5 g / l Al 3+ The foil was electrochemically grained within 10 seconds using an alternating current in an aqueous solution of ions. The foils were then descaled by etching with an aqueous solution containing 5.5 g / l NaOH for 2 seconds at 36°C and rinsed with demineralized water for 2 seconds. followed by a temperature of 50°C and 17 A / dm 2 The foil was anodized for 15 seconds in an aqueous solution containing 145 g / l sulfuric acid at a current density of 15 s, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com