Microreaction channel, reaction substrate and microchannel reactor

A micro-reaction channel and micro-channel technology, applied in chemical/physical/physical-chemical reactors, chemical instruments and methods, chemical/physical/physical-chemical processes, etc., can solve the problems of difficult processing, poor mixing effect, etc. The effect of good mixing effect, convenient production and processing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

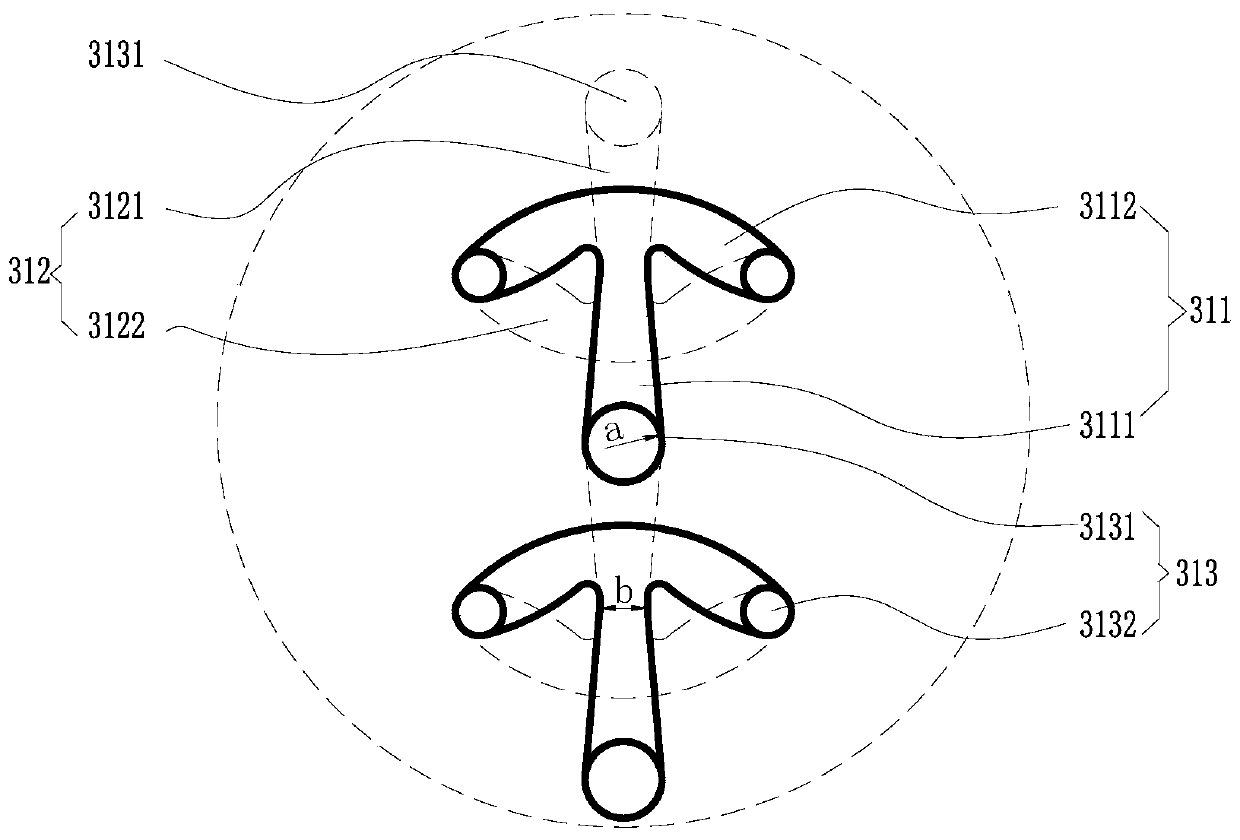

[0054] Please also refer to figure 1 and image 3 , the micro-reaction channel provided by the present invention is now described. The micro-reaction channel is arranged on the substrate 31, one side of the substrate 31 is formed with at least two first microchannel units 311 arranged in sequence, and the other side of the substrate 31 is formed with at least two microchannel units arranged in sequence. The second microchannel unit 312, the first microchannel unit 311 and the second microchannel unit 312 are arranged alternately, and the end of the first microchannel unit 311 and the head end of the second microchannel unit 312 The end of the second microchannel unit 312 communicates with the head end of the next first microchannel unit 311 .

[0055] Compared with the prior art, the micro-reaction channel provided by the present invention is composed of several first micro-channel units 311 and second micro-channel units 312 connected in sequence, and the first micro-channe...

Embodiment 2

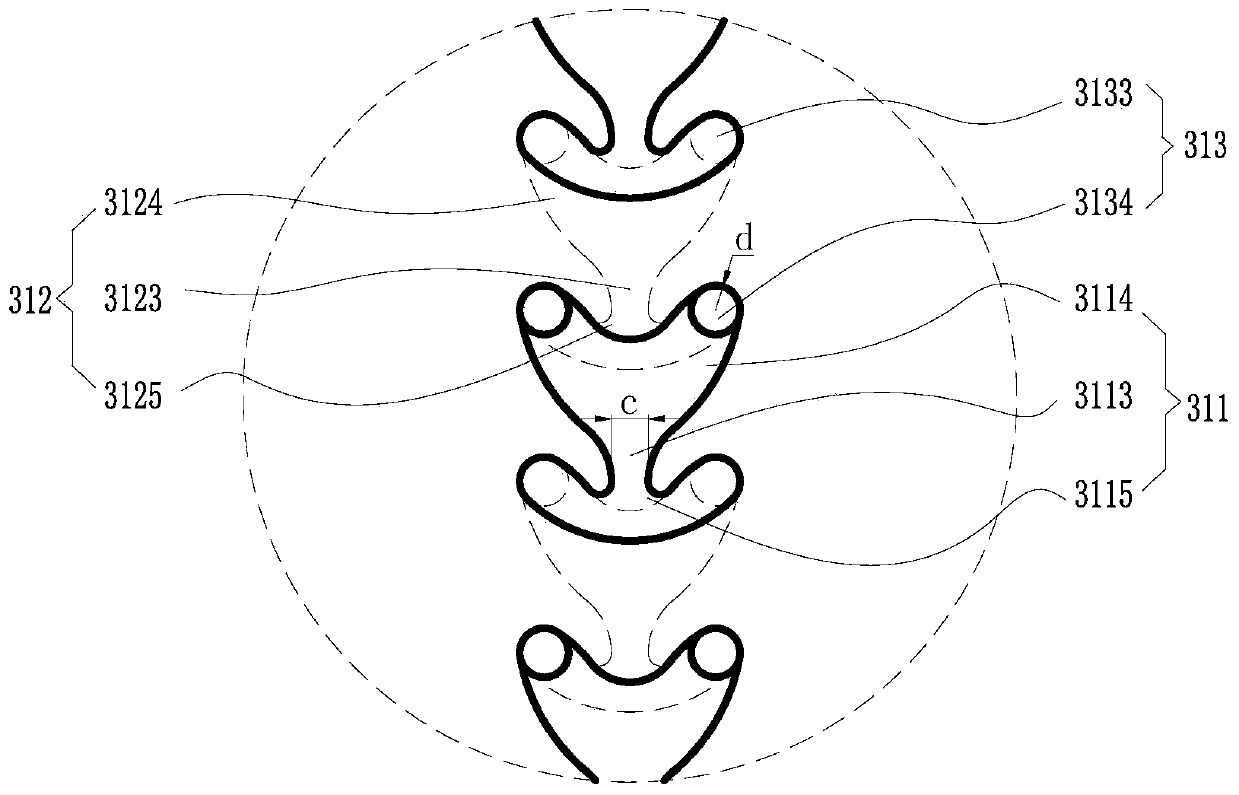

[0062] see figure 2 and image 3 , as another specific embodiment of the micro-reaction channel provided by the present invention, the difference between this embodiment and embodiment 1 is that the shapes of the first micro-channel unit 311 and the second micro-channel unit 312 are different. In this embodiment, the shapes and directions of the first microchannel unit 311 and the second microchannel unit 312 are consistent or the first microchannel unit 311 and the second microchannel unit 312 are arranged symmetrically, and the first microchannel unit 311 and the second microchannel unit 312 are arranged symmetrically. The second microchannel units 312 are arranged at intervals, the shapes of the first microchannel unit 311 and the second microchannel unit 312 are both cardioid-like, and arc-shaped channels are connected to the bottom ends of the cardioid-like shapes.

[0063] Specifically, the first microchannel unit 311 includes a third main channel 3113, a third branch ...

Embodiment 3

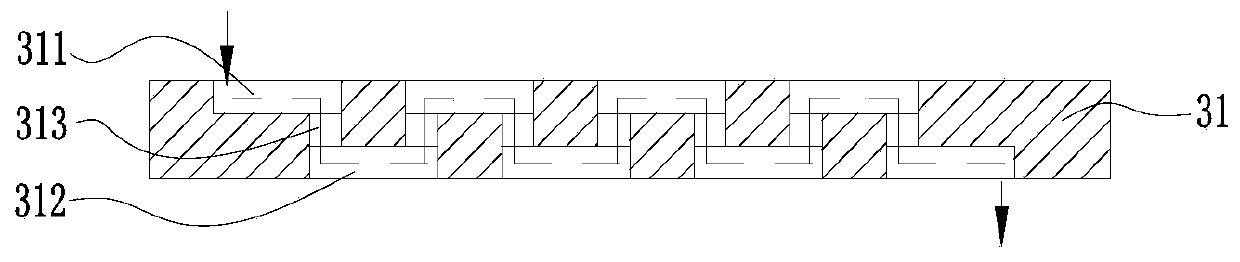

[0072] see Figure 4 to Figure 6 , Figure 10 to Figure 12 as well as Figure 16 , the present invention also provides a reaction substrate 3, and the reaction substrate 3 provided by the present invention will now be described. The reaction substrate 3 includes a substrate 31 and a cover plate 32, and the two sides of the substrate 31 are respectively provided with at least two groups of micro-reaction channels as described in embodiment 1 or embodiment 2 and connecting two adjacent micro-reaction channels. The connecting channel 314 ; the cover plates 32 are located on opposite sides of the substrate 31 , and the two cover plates 32 are respectively covered on the first micro-channel unit 311 and the second micro-channel unit 312 .

[0073] The reaction substrate 3 provided by the present invention is directly processed and grooved on the substrate 31 to respectively form the first microchannel unit 311, the second microchannel unit 312 and the connecting channel 314, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com