Poultry manure fermentation and biochemical device

A biochemical and poultry manure technology, applied in fertilization equipment, applications, climate change adaptation, etc., can solve the problems of low automation, inability to feed and discharge materials by itself, large extrusion, etc., to achieve wide application range and save manpower , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below.

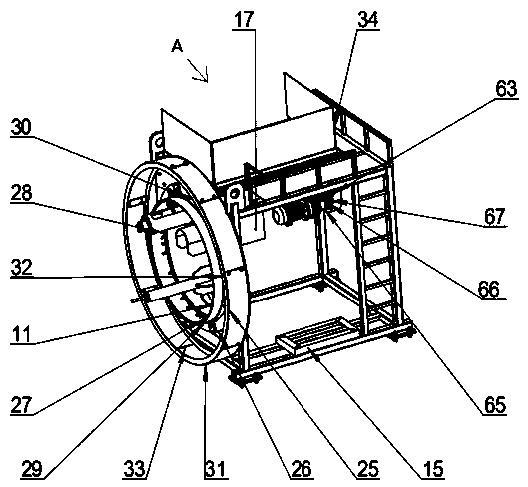

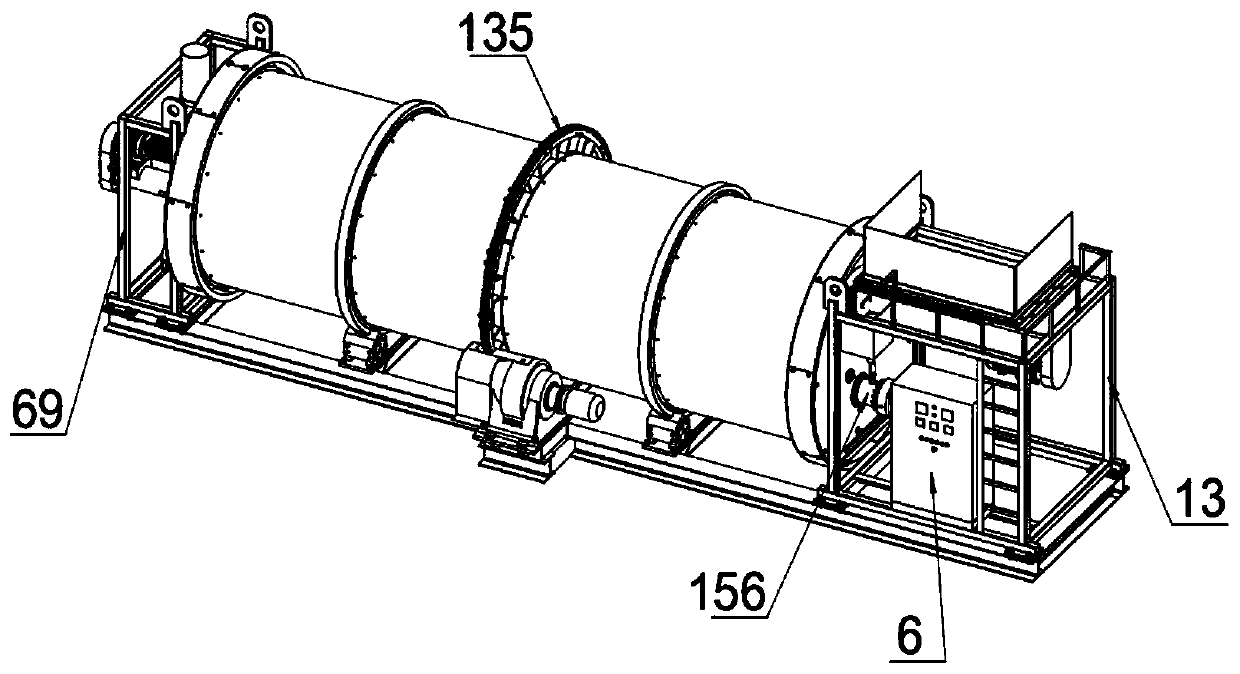

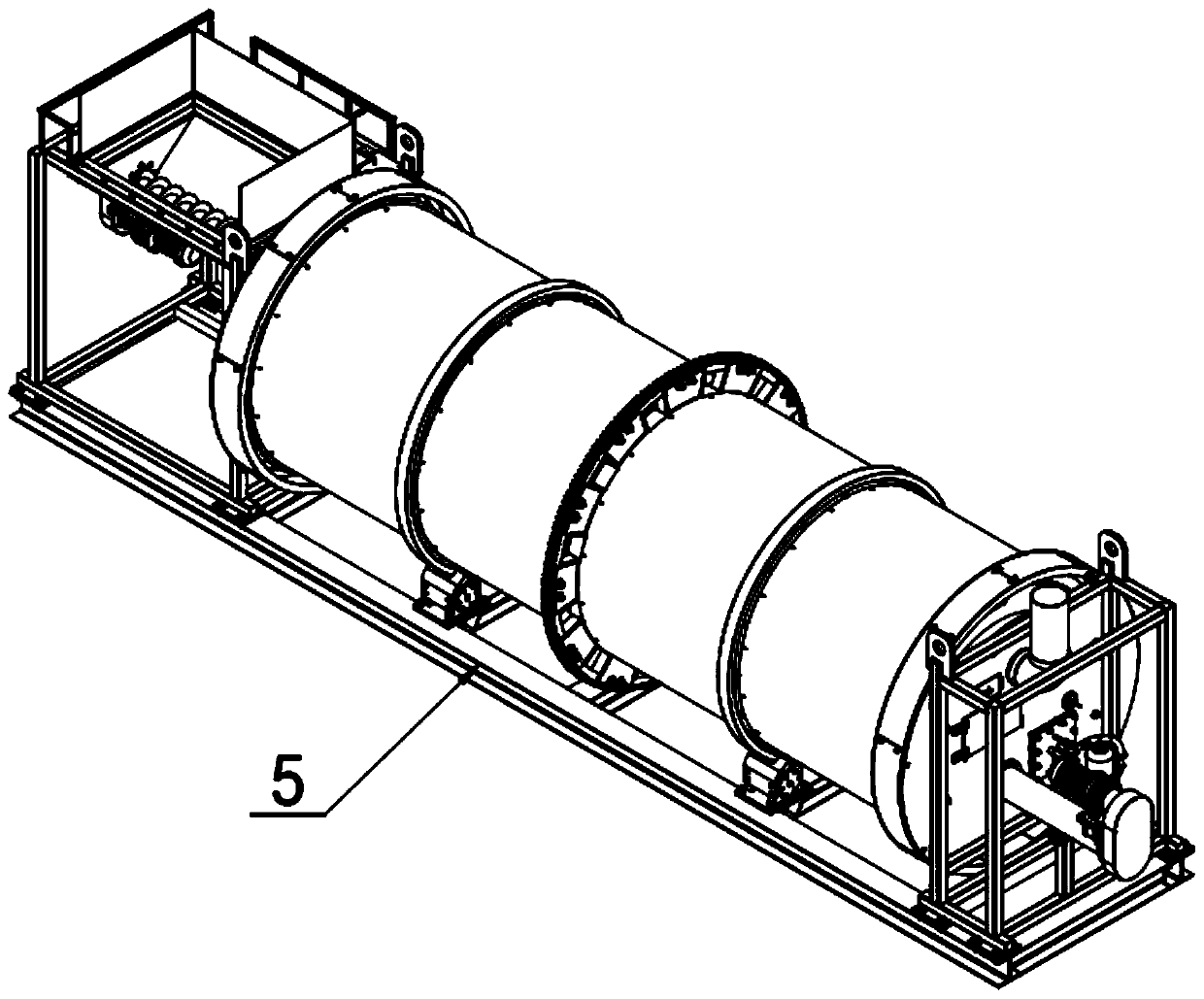

[0049] Such as Figure 1 to Figure 4 As shown, the present invention includes a feed assembly, a discharge assembly, a barrel assembly, a heating system, a base assembly and a control system;

[0050]The feed assembly includes a feed frame 13, the side of the feed frame 13 is fixed with a vertically placed feed plate 9, and the two sides of the feed plate 9 are respectively fixedly connected with two feed side sealing plates 10. The end face of the feeding plate 9 is provided with a horizontally placed feeding temperature measuring device 7, and four feeding temperature measuring device reinforcing plates 8 are evenly distributed around the feeding temperature measuring device 7, and the feeding temperature measuring device reinforcing plates 8 are respectively It is fixedly connected with the feed temperature measuring device 7 and the feed flat plate 9; the end face of the feed flat plate 9 is fixed with a heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com