A method for quickly changing tool strings and wellheads in conjunction with bridge plug perforation under pressure

A technology of tool strings and bridge plugs, which is applied in the field of rapid replacement of tool strings and wellheads in conjunction with bridge plug perforation under pressure, which can solve the problems of time-consuming and labor-consuming, and achieve simple replacement of wellheads and tool strings and maximum construction efficiency Minimize and avoid the effect of working at heights and under pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings.

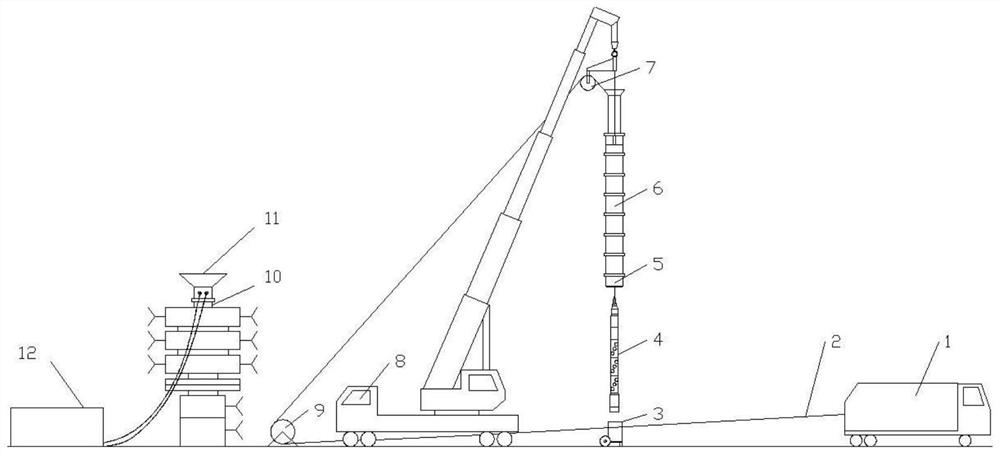

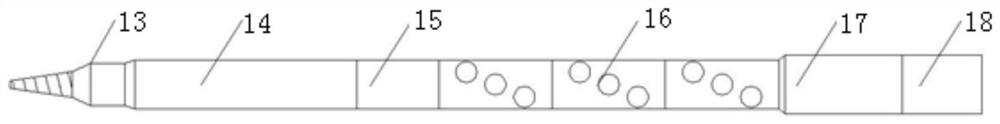

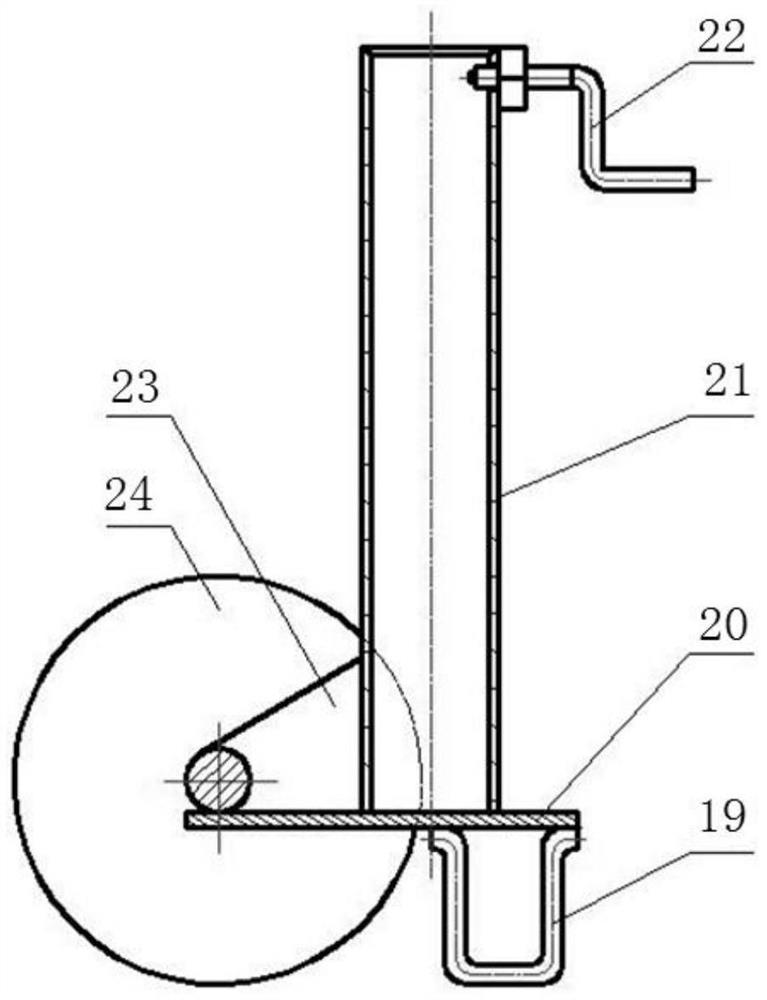

[0040]The method of the present invention for the rapid replacement of the tool string and the wellhead for bridge plug perforation with pressure is as follows: the plug-in wellhead device is connected between the wellhead 10 and the cable blowout preventer 6, and connected at the top of the tool string 4 The flexible fishing head 13 of the protection cable is installed at the bottom to protect the bridge plug and support the support wheel seat 3 of the tool string. Through the remote control of the plug-in wellhead device, the automatic connection and separation of the cable blowout pipe 6 and the wellhead 10 can be directly realized; at the same time, the cable blowout pipe 6 and the tool string 4 can be hoisted close to or separated from the wellhead 1 through the cooperation of the crane 8 and the winch 1 Wellhead. Utilize the flexible salvage head 13 to protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com