Oscillating floater type wave energy collection and friction power generation device

A technology of friction power generation and wave energy, applied in the directions of friction generators, ocean energy power generation, transmission devices, etc., can solve the problems of poor adaptability to environmental wave conditions, easy corrosion of wave power generation devices, and low energy utilization rate, etc., and achieve mechanical transmission structure. The effect of compactness, improved corrosion resistance and storm damage resistance, and high scientific and technological content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

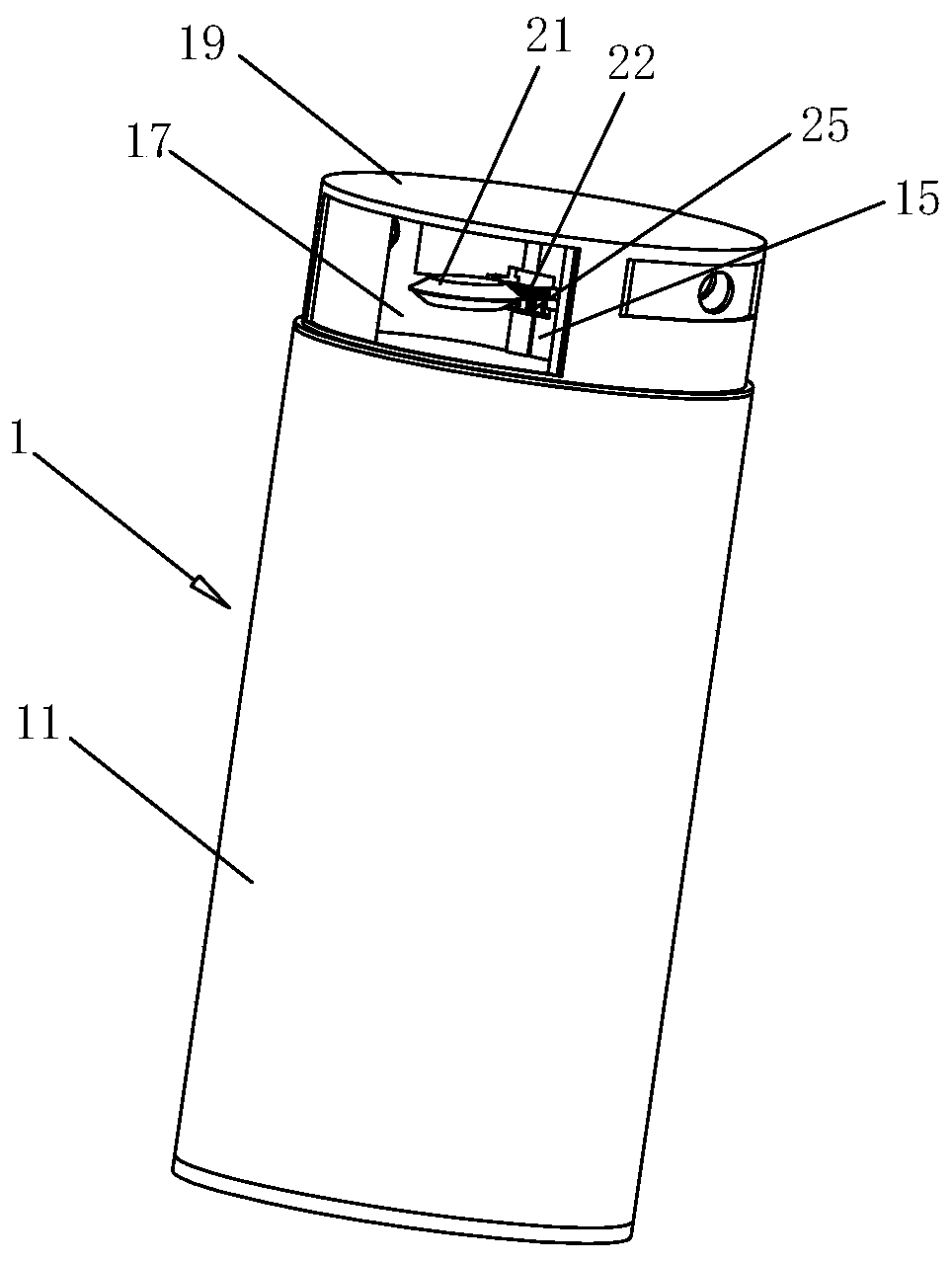

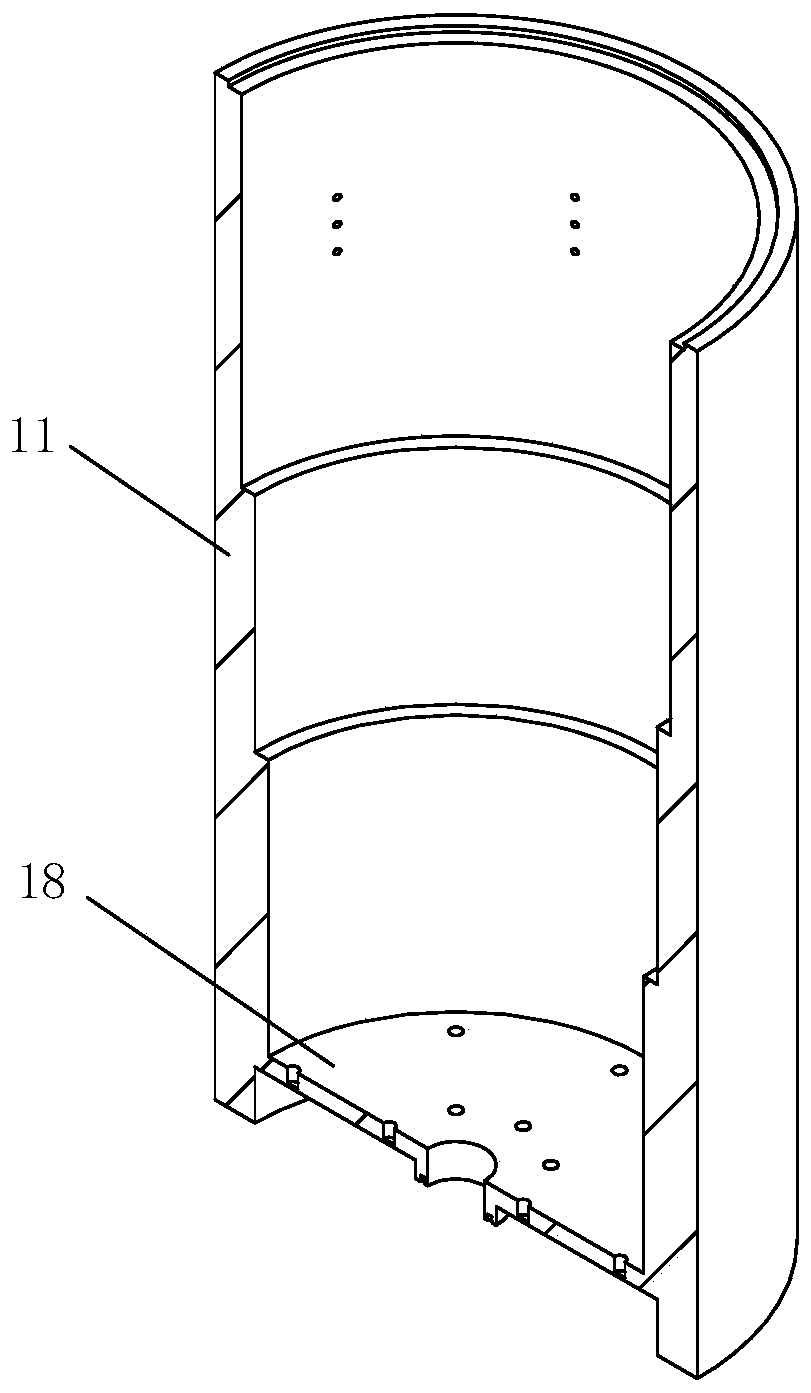

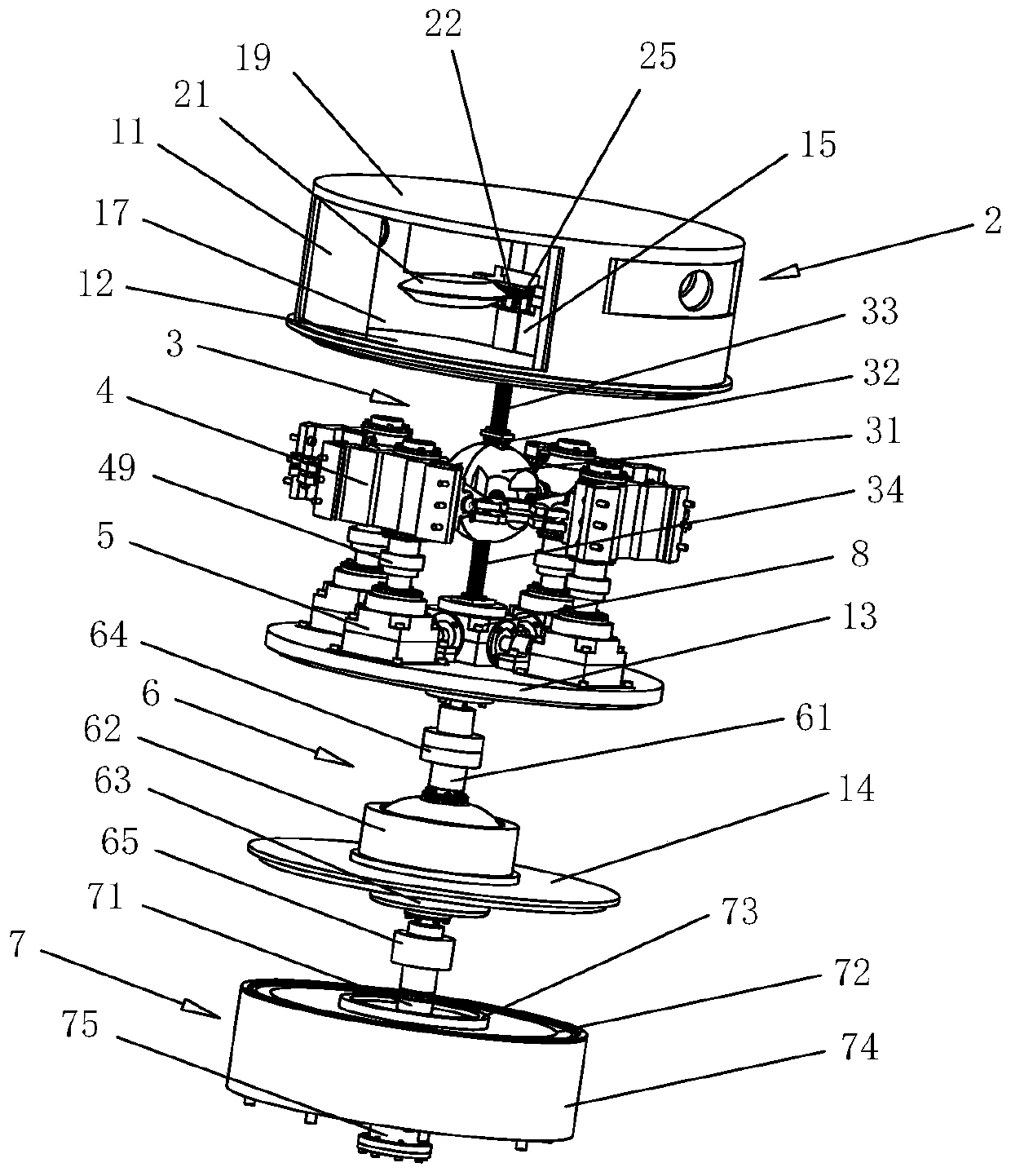

[0063] The present invention is described in detail below in conjunction with accompanying drawing:

[0064] combine Figure 1 to Figure 15 , an oscillating floating wave energy collection friction power generation device, including a casing 1, an energy collection unit 2, a resonance gear mechanism 3, a rocker transmission component 4, an angle transmission component 5, a speed-up component 6 and a friction power generation unit 7, the casing 1 is a cylindrical structure with a closed bottom, which is composed of a circular cylinder wall 11, a cylinder bottom 18 and a top cover 19, and the outer edge of the cylinder bottom 18 is fixed and sealed with the lower end of the circular cylinder wall 11 to form an integral structure to realize For the sealing of the bottom of the circular cylinder wall 11, the outer edge of the top cover 19 and the upper end of the circular cylinder wall 11 are fixed and sealed to form an integral structure, so as to realize the sealing of the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com