Air source super heat pump and heat extraction method thereof

A kind of air source, super technology, applied in the direction of machines using waste heat, machine operation mode, heat recovery system, etc., can solve problems such as inability to guarantee continuous hot water production, low evaporation temperature, and frost on the surface cooler surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

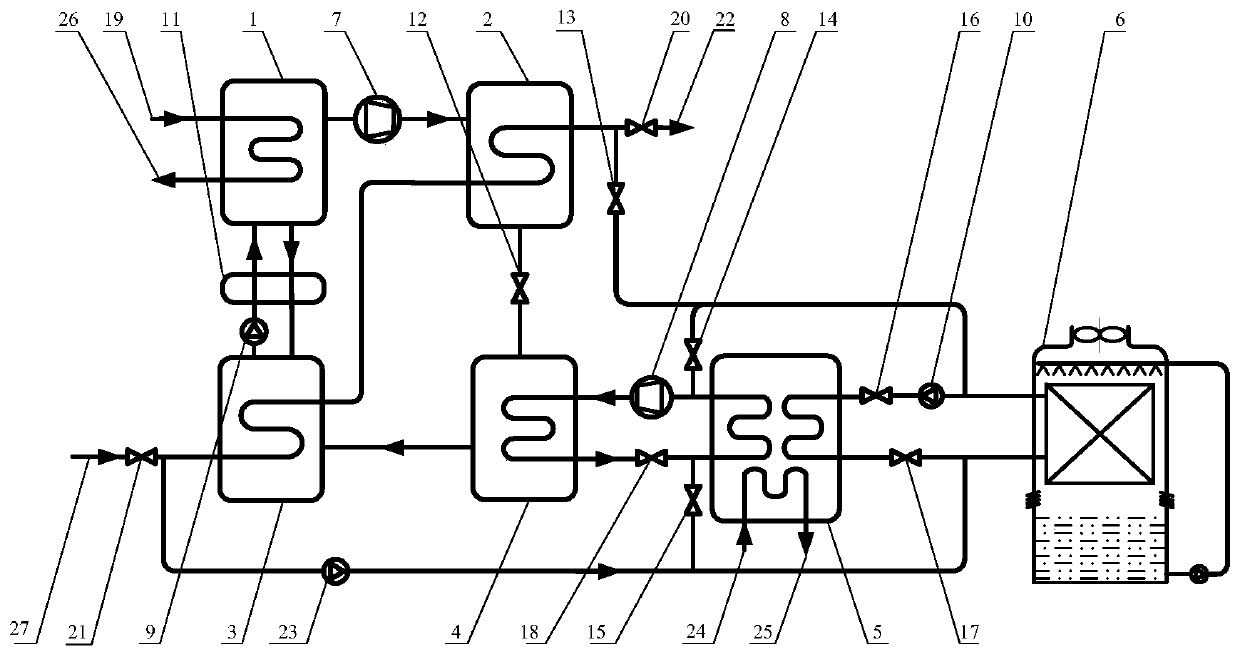

[0027] The heat extracted by the air source super heat pump of the present invention is to extract or release heat from the air by means of a heat pump unit that uses air energy to produce hot water or cold water to achieve the purpose of heating or cooling in a wide range. The following three operating modes are used to extract heat from the air Heat to meet heating or cooling needs: In this embodiment, the internal circulating working fluid uses methylpyrrolidone as working fluid A, difluoroethanol as working fluid B, carbon dioxide as working fluid C, and ethylene glycol as working fluid D. Alcohol drives the water vapor generated by the heat source steam boiler.

[0028] 1. Simultaneous heating and cooling

[0029] In this operation mode, close B valve 13, C valve 14, D valve 15 and C circulation pump 23, open I valve 21, H valve 20, A valve 12, E valve 16, F valve 17 and B circulation pump 10, and open A Compressor 7 and B compressor 8, hot water passes through hot water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com