Device for ultrasonic ranging and ranging method thereof

A technology of ultrasonic waves and ultrasonic probes, applied in the direction of measuring devices, sound wave re-radiation, radio wave measuring systems, etc., can solve the problems of reducing the test accuracy of ultrasonic ranging devices and increasing ranging errors, so as to improve the service life and use Safe and convenient, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

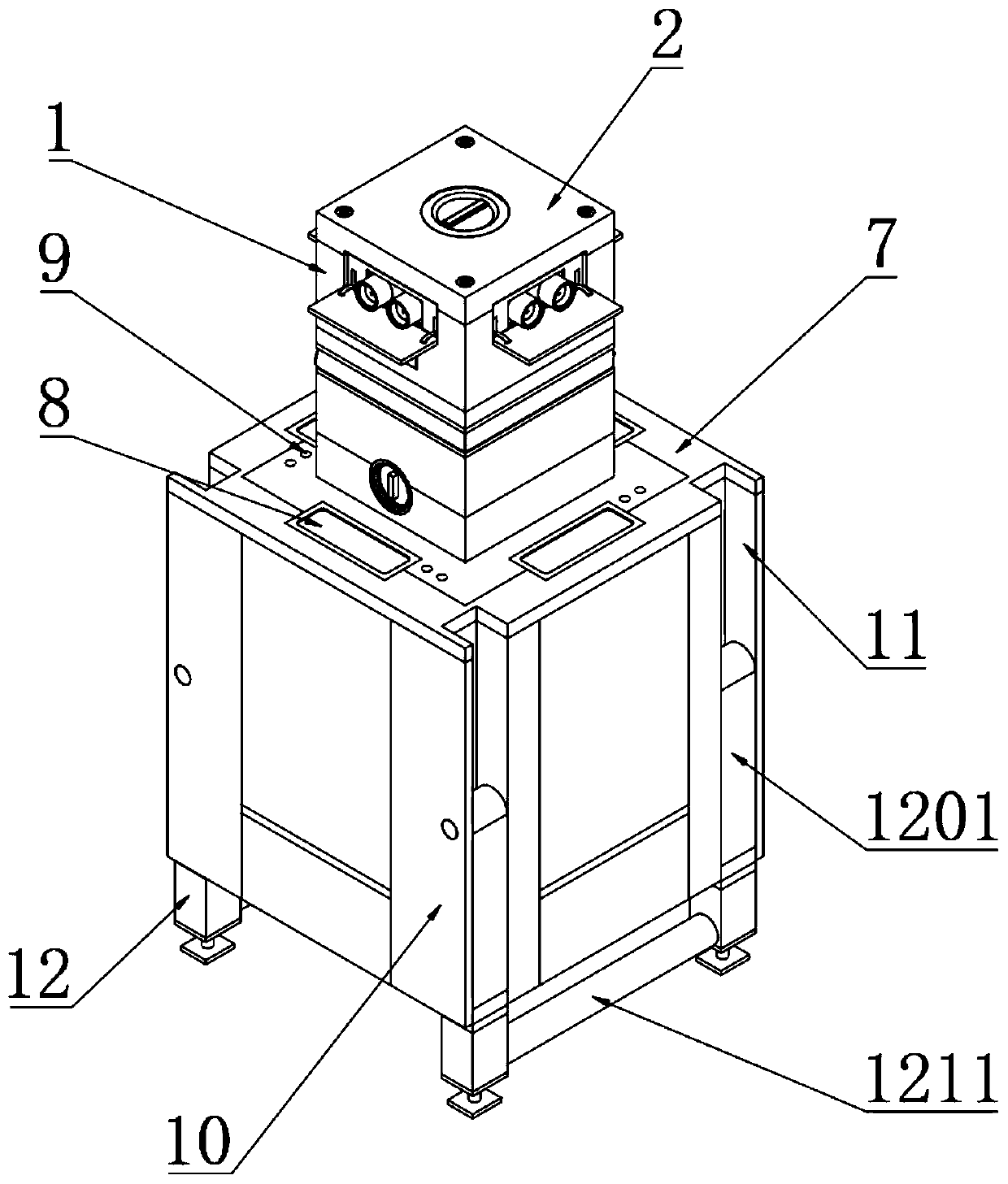

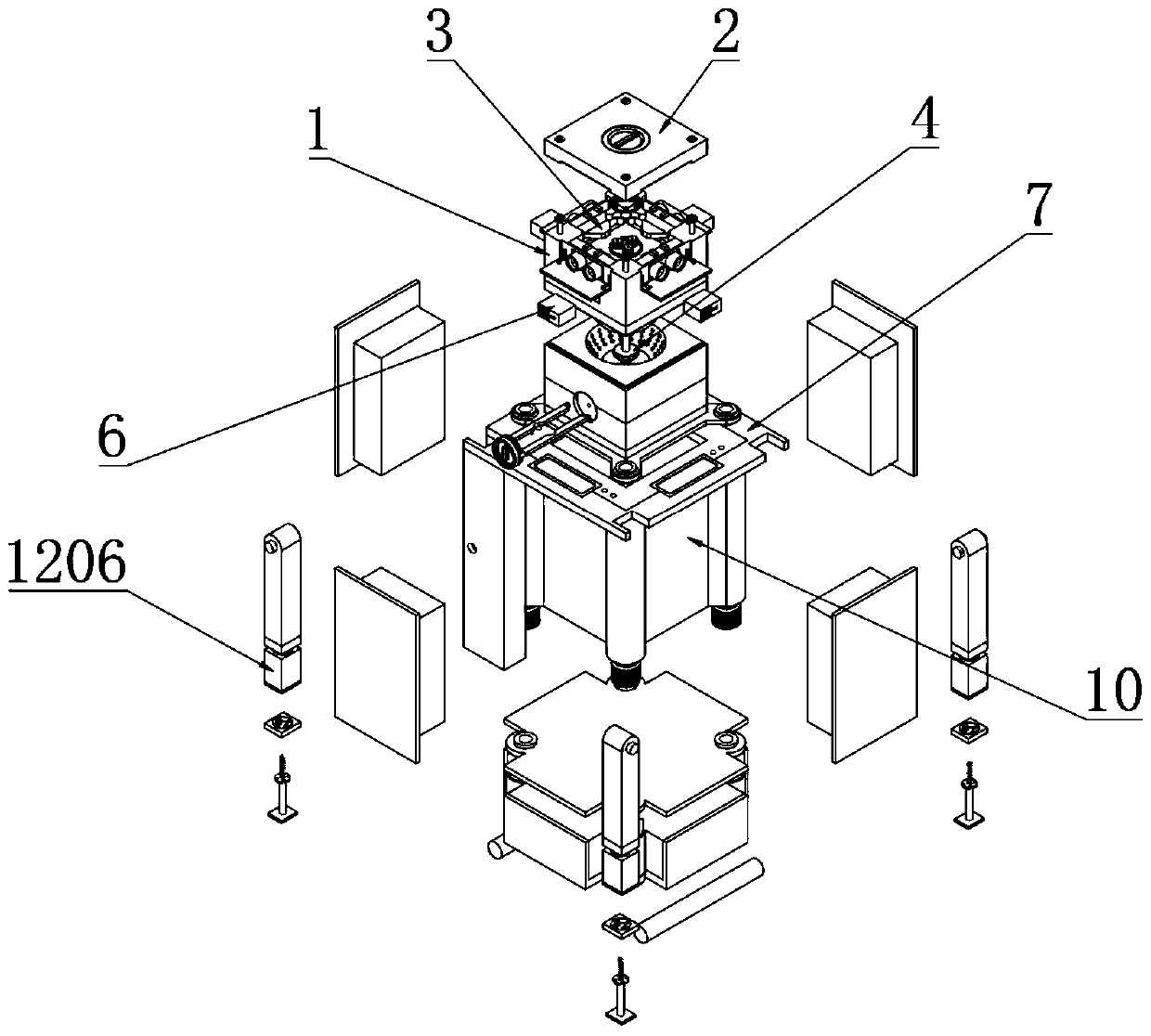

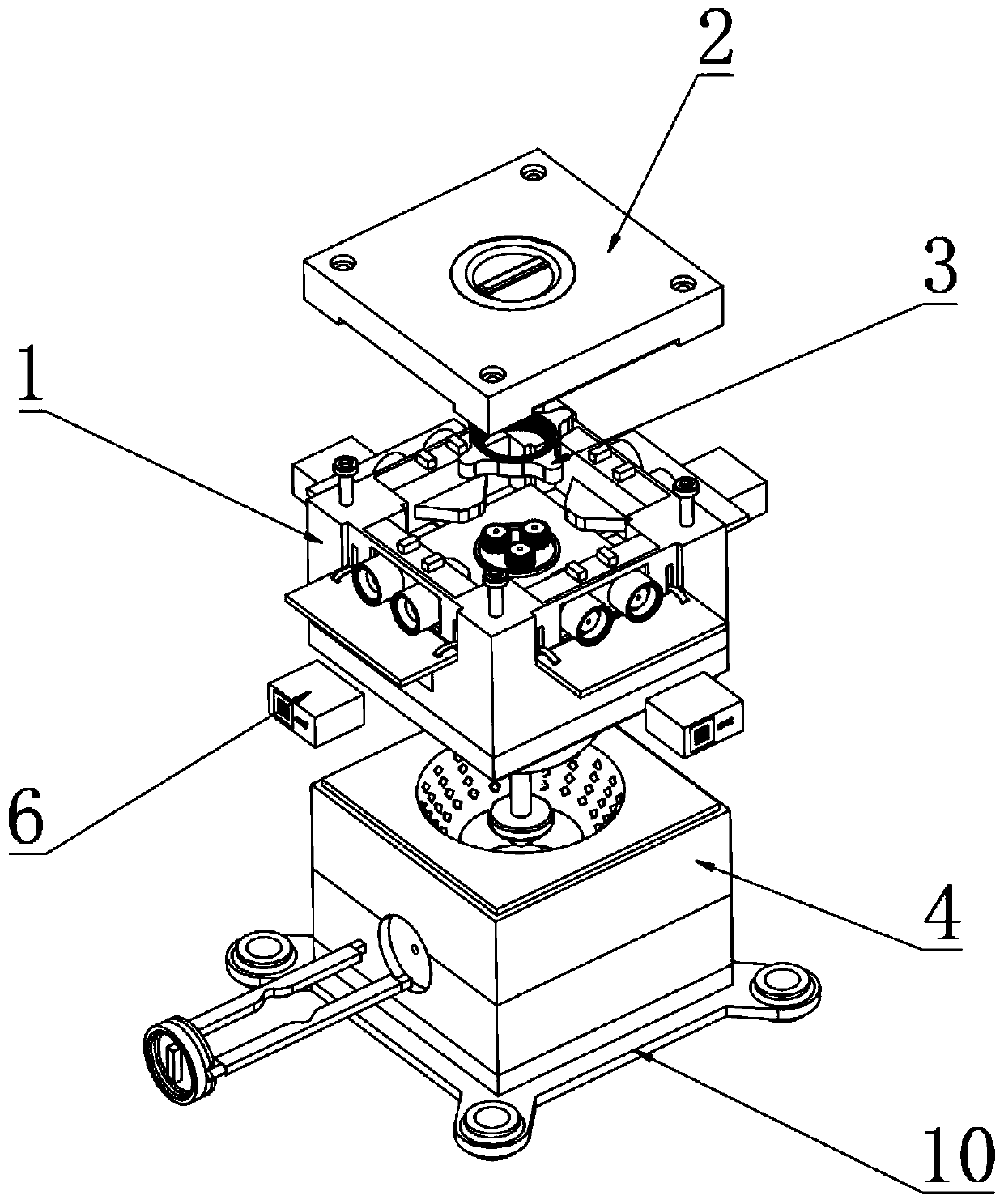

[0066] Example: such as Figure 1-10 As shown, the present invention provides a technical solution, a device for ultrasonic distance measurement, including an upper installation box 1, the top of the upper installation box 1 is fixedly connected with a fixed cover 2 through an inner hexagonal bolt, and the upper installation box 1 is internally provided with Protective ejection mechanism 3;

[0067] The protective ejection mechanism 3 includes an installation side cavity 301, a guide chute 302, a storage spring 303, a small driving plate 304, an ultrasonic probe 305, an ejection triangular plate 306, a limit frame 307, an ejection rotating plate 308, a transmission gear 309, Driving gear 310, driving motor 311, sealing rotating plate 312, receiving vertical groove 313 and return spring piece 314;

[0068] The four sides inside the upper installation box 1 are provided with an installation side chamber 301, and the bottom end of the inner side of the installation side chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com