Dynamic stress analysis method in nuclear fuel fission crushing process

A nuclear fuel and kinetic technology, applied in fuel elements, nuclear power generation, greenhouse gas reduction, etc., can solve problems such as damage and plastic damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

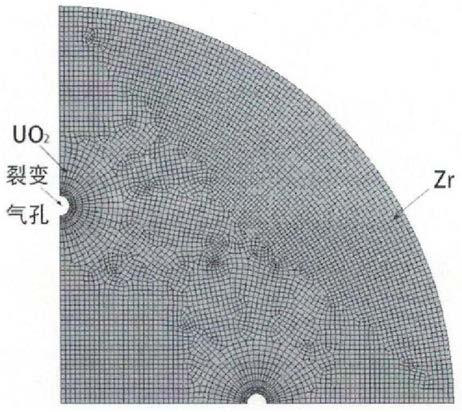

[0015] The outside of the fuel plate is a Zr alloy cladding, and the inside is a UO2 core, and at the same time, small particles of UO2 and Zr, pores, etc. are mixed. The pores, UO2 and Zr particles are all assumed to be spherical, so they meet the axisymmetric problem and can be simplified to a plane problem. In order to realize the application of surface load in LS-DYNA, a three-dimensional thin slice is established as a geometric model with the center point of the sphere (thickness is 0.005mm), and only one layer of cells is divided in the thickness direction, thereby greatly reducing the amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com