Air pressure regulated magnetic control film transfer printing stamp and transfer printing method

A technology of air pressure regulation and magnetic thin film, which is applied in the manufacture of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc. It can solve the problems of limited pick-up force and inability to pick up electronic devices, and achieve precise and selective transfer printing with low production costs. , to achieve the effect of selective transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

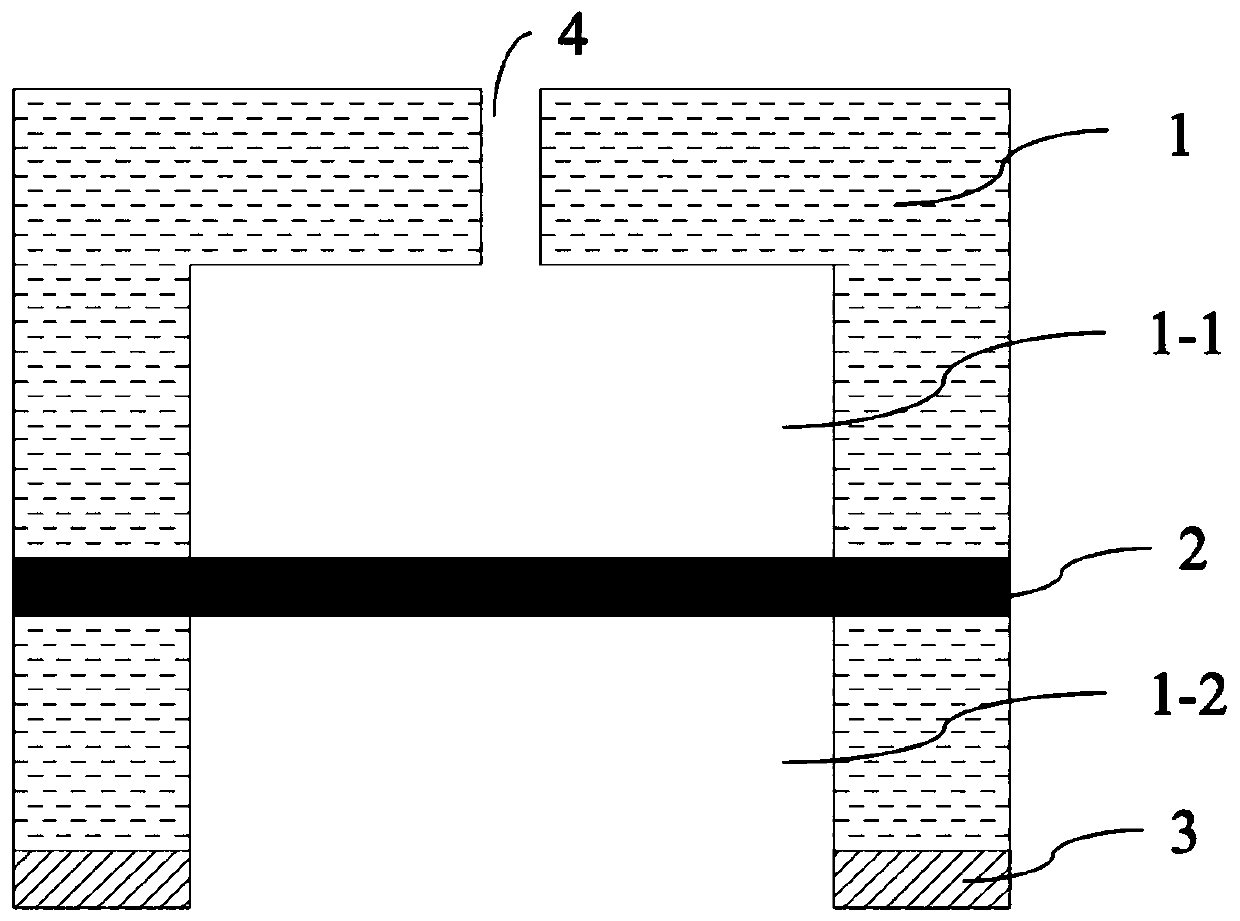

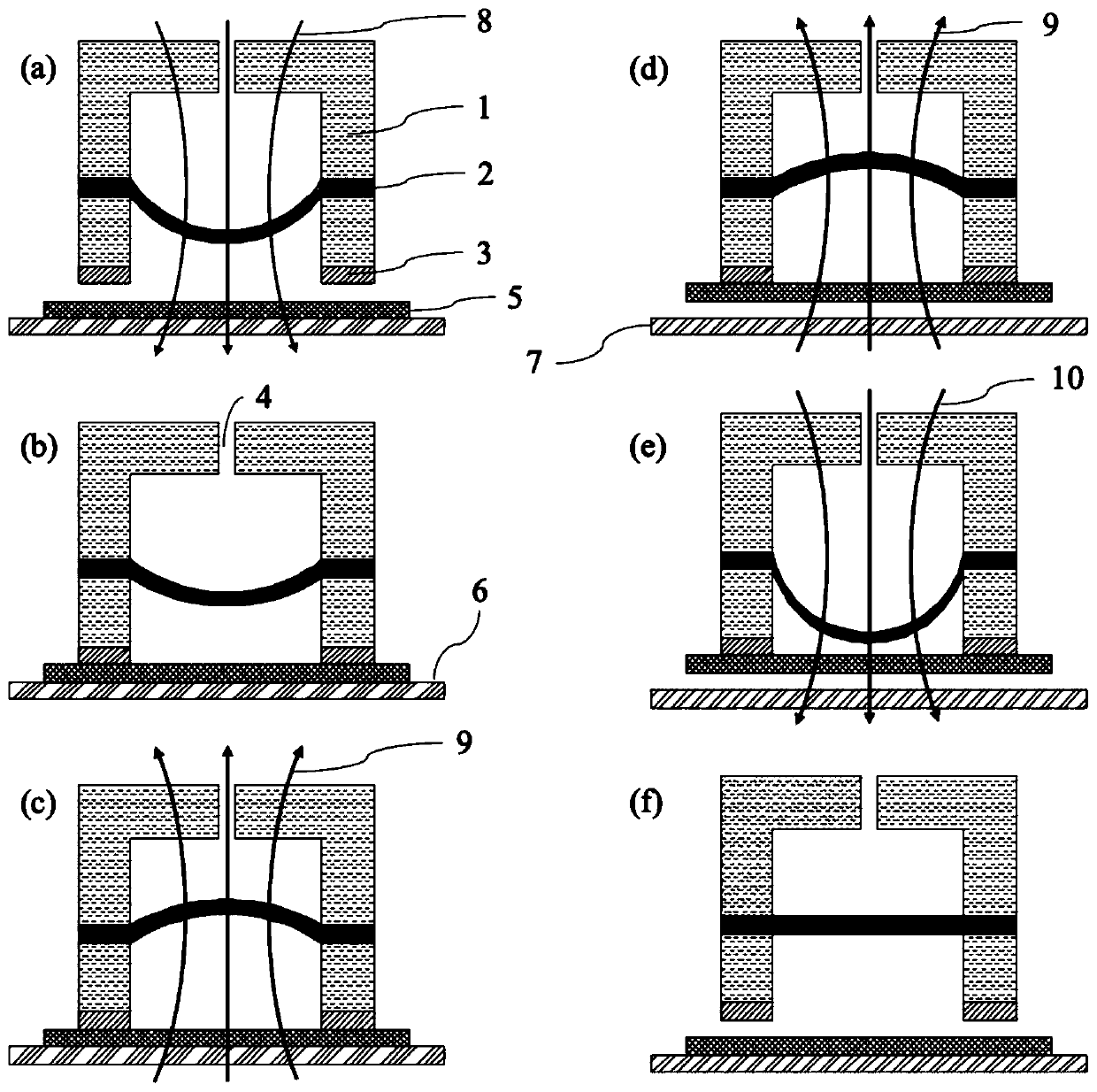

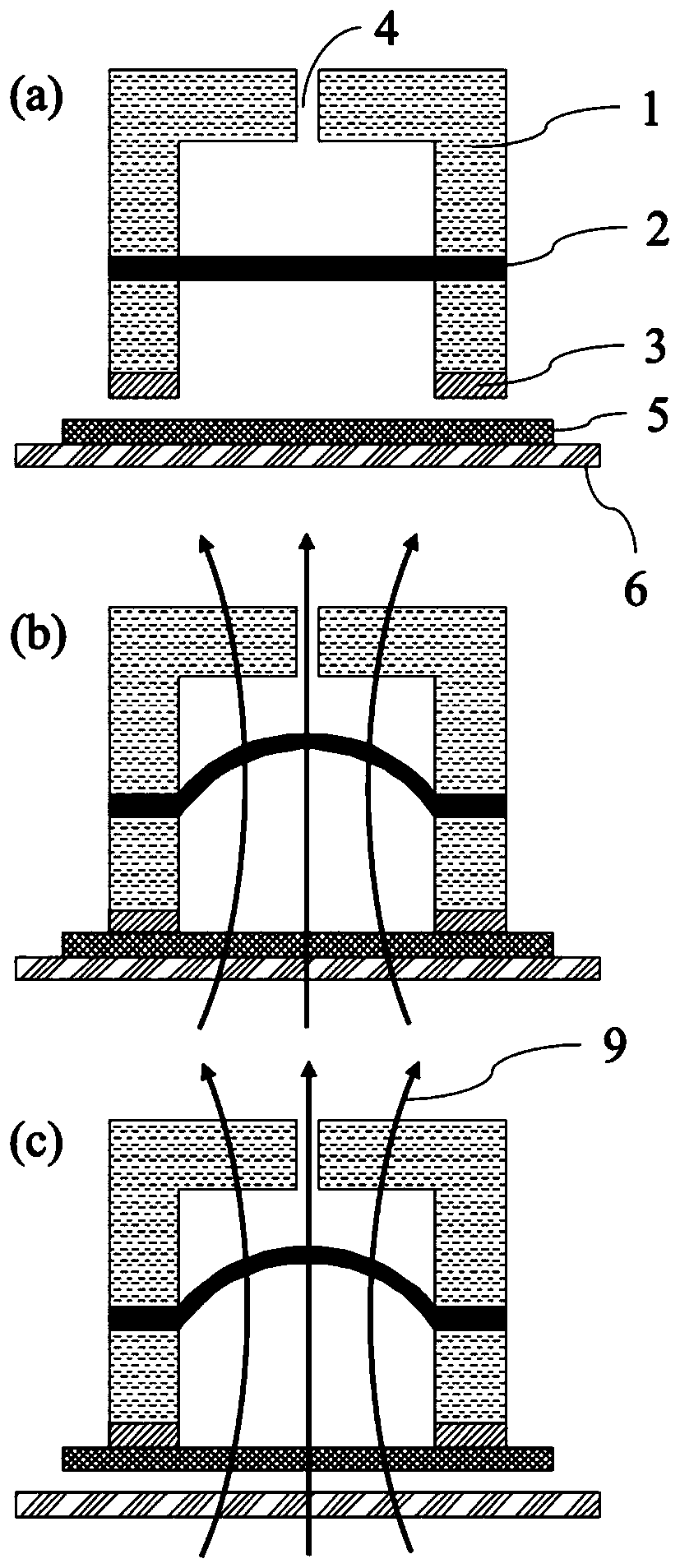

[0032] As an example, but not to limit the scope of the invention, figure 1 It is a structural schematic diagram of the smallest unit of the magnetic control thin film transfer stamp of the air pressure regulation of the present invention. The material of the stamp body 1 is PDMS prepared with a cavity array (the ratio of the curing agent to the body is 1:10), and the top of the stamp body 1 is also provided with a vent hole 4 communicating with the cavity, and the magnetic film 2 divides the cavity into There are two upper and lower layers, of which the upper layer is the upper cavity 1-1 with vent holes 4, and the lower layer is the lower cavity 1-2 that completely penetrates the bottom of the stamp; the material of the bottom surface 3 of the stamp is the curing agent and the ratio of the body is 1:20 PDMS; the material of the magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com