Beneficiation process of medium and low grade mixed collophanite

A hybrid, colloidal phosphate rock technology, applied in flotation, solid separation and other directions, can solve the problems of energy saving and consumption reduction, large consumption of chemicals, and high energy consumption of grinding, so as to reduce the processing capacity of grinding and improve the quality of grinding. Selectivity and the effect of improving beneficiation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

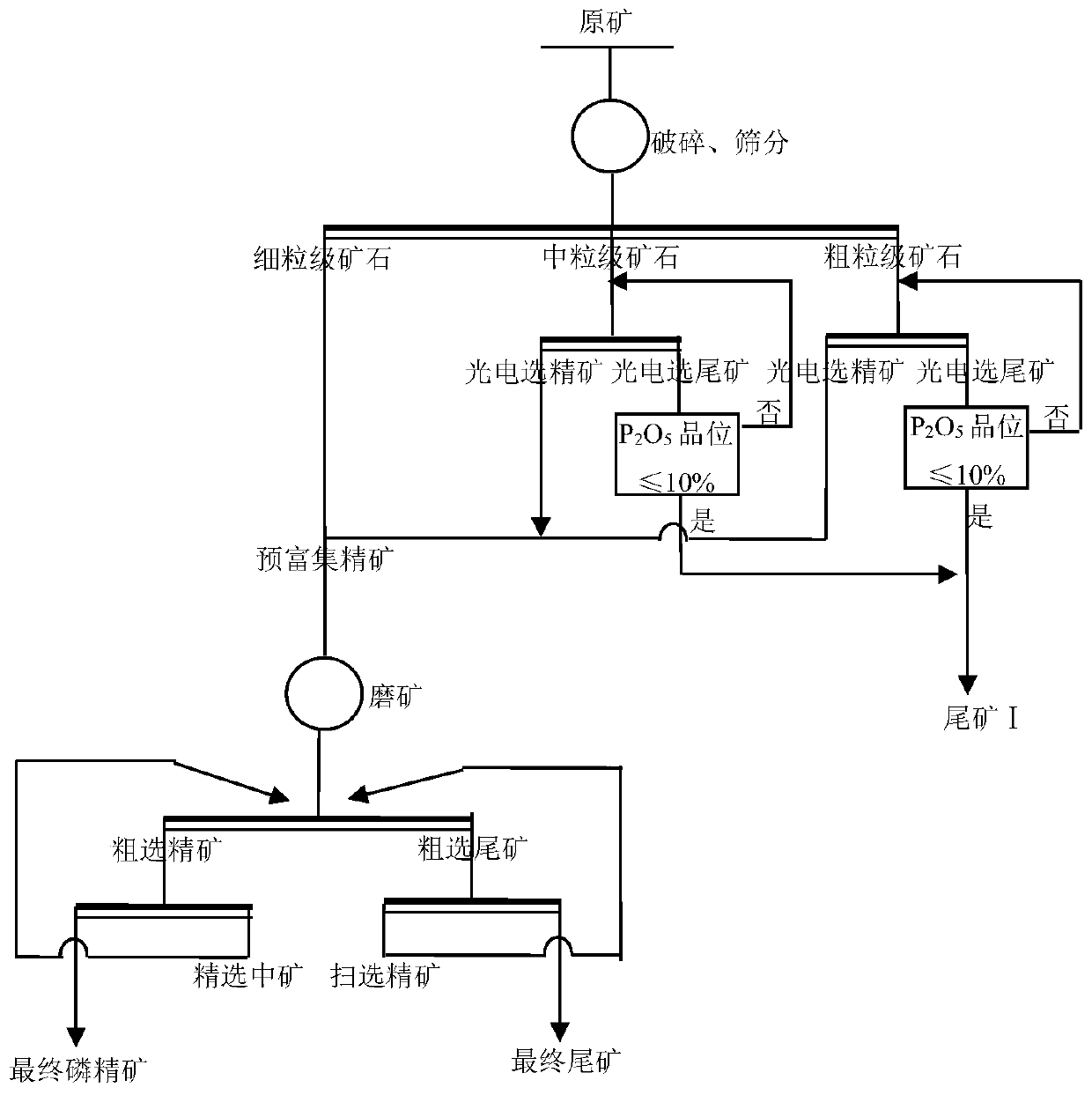

[0046] A medium and low grade mixed collophosite, taken from a dressing plant in Mabian area, P 2 o 5 The grade is 22%, and its beneficiation process is as follows figure 1 shown, including the following steps:

[0047] S1. Crushing the raw ore to obtain crushed ore with a particle size ≤ 60mm;

[0048] S2. Screen the broken ore to obtain fine-grained ore with a particle size of ≤8mm and coarse-grained ore with two different particle sizes of +8-30mm and +30-60mm;

[0049] S3. Carry out photoelectric separation to two coarse-grained ores respectively to obtain their respective photoelectric separation concentrates and photoelectric separation tailings;

[0050] S4. Return the photoelectric separation tailings of the two particle sizes to step S3 respectively and repeat 2 to 3 times until P in the photoelectric separation tailings 2 o 5 Stop when the grade is less than or equal to 10%; among them, each photoelectric separation of the same particle size can obtain the respe...

Embodiment 2

[0062] A medium and low grade mixed collophosite, from Leibo Plant, P 2 o 5 The grade is 20%, and its beneficiation process is as follows figure 1 shown, including the following steps:

[0063] S1. Crushing the raw ore to obtain crushed ore with a particle size ≤ 60mm;

[0064] S2. Screen the crushed ore to obtain a fine-grained ore with a particle size of ≤8mm and a coarse-grained ore divided into two different particle sizes of -+8-30mm and +30-60mm;

[0065] S3. Carry out photoelectric separation to two coarse-grained ores respectively to obtain their respective photoelectric separation concentrates and photoelectric separation tailings;

[0066] S4. Return the photoelectric separation tailings of the two particle sizes to step S3 respectively and repeat 2 to 3 times until P in the photoelectric separation tailings 2 o 5 Stop when the grade is less than or equal to 10%; among them, each photoelectric separation of the same particle size can obtain the respective photoe...

Embodiment 3

[0078] A medium and low grade mixed collophosite, taken from a concentrator in Jinyang, P 2 o 5 The grade is 18%, and its beneficiation process is as follows figure 1 shown, including the following steps:

[0079] S1. Crushing the raw ore to obtain crushed ore with a particle size ≤ 60mm;

[0080] S2. Screen the broken ore to obtain fine-grained ore with a particle size of ≤ 8mm and coarse-grained ore divided into two different particle sizes of +8-30mm and +30-60mm;

[0081] S3. Carry out photoelectric separation to two coarse-grained ores respectively to obtain their respective photoelectric separation concentrates and photoelectric separation tailings;

[0082] S4. Return the photoelectric separation tailings of the two particle sizes to step S3 respectively and repeat 2 to 3 times until P in the photoelectric separation tailings 2 o 5 Stop when the grade is less than or equal to 10%; among them, each photoelectric separation of the same particle size can obtain the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com