Dental zirconia all-ceramic material and preparation method thereof

A zirconia and dental technology, applied in the field of dental zirconia all-ceramic materials and their preparation, can solve problems such as failure to improve the powder microstructure, and achieve the effects of being beneficial to cell proliferation, reducing the probability of occurrence and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

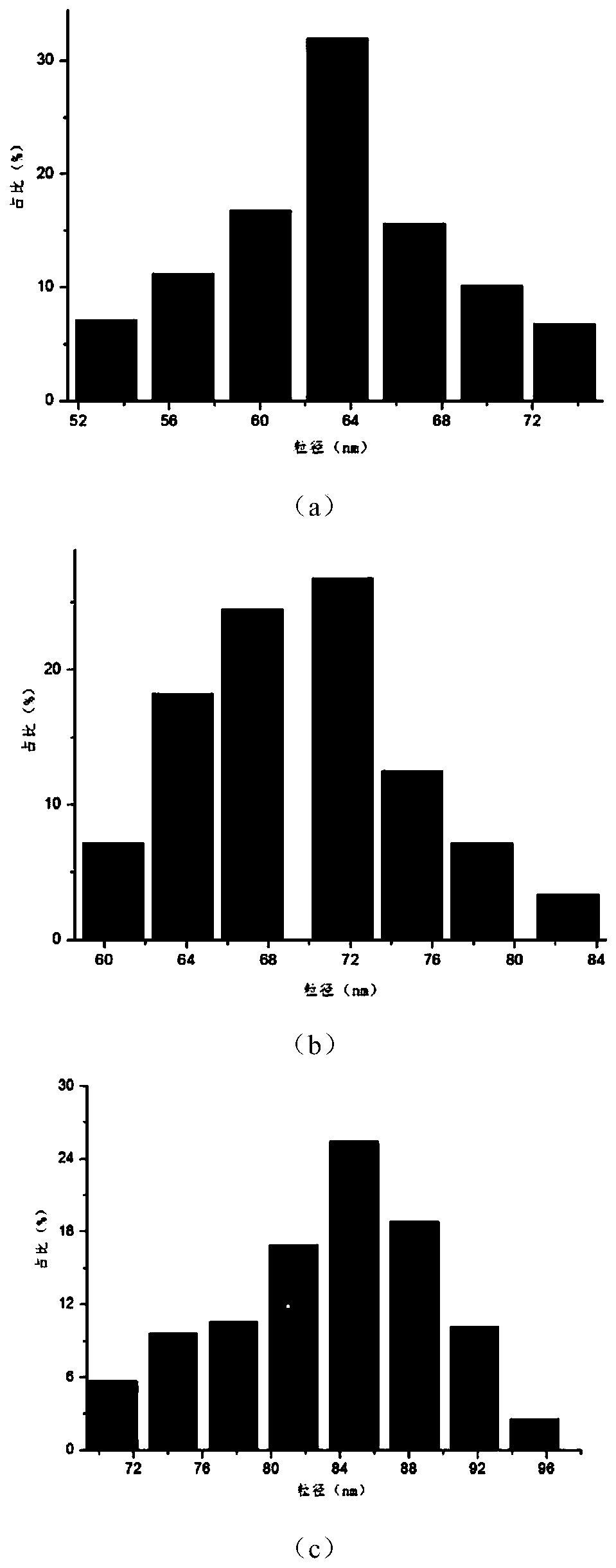

Embodiment 1

[0027] This embodiment discloses a dental zirconia all-ceramic material, which is prepared by using the polyacrylamide gel method to prepare nano-ZrO 2 Synthesis of powder by dry pressing. Conventional preparation of ZrO 2 Powder methods include hydrothermal synthesis, microemulsion, co-precipitation, and sol-gel methods. The polyacrylamide gel method is an improved sol-gel method, which has the advantages of low cost, simple operation, and adjustable powder composition. Nano-ZrO 2 The powder is made of ZrOCl by using 2 ·8H 2 O and ZrO(NO 3 ) 2 2H 2 The gel precursor prepared from the composite zirconium source composed of O is prepared through gel thermal decomposition steps and crystallization steps to obtain powder particle sizes distributed in the range of 60.4 to 82.6 nm. Specifically, ZrOCl 2 ·8H 2 O and ZrO(NO 3 ) 2 2H 2O is configured as a 0.4mol / L aqueous solution at a molar ratio of 1:1. Then, acrylamide (AM) and methylenebisacrylamide (N,N'-methylene b...

Embodiment 2

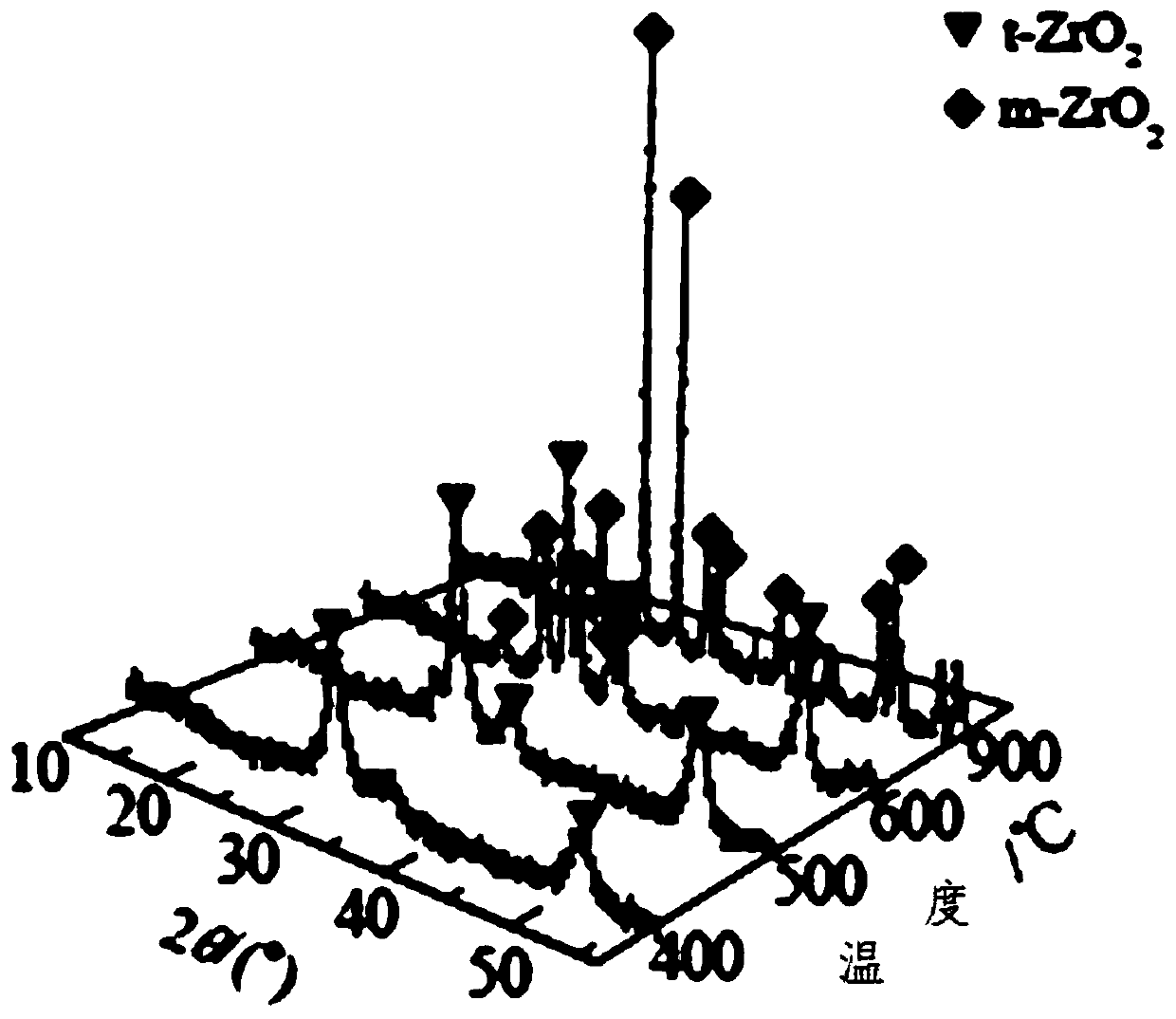

[0045] The invention also discloses a preparation method of a dental zirconia all-ceramic material, which includes nano-ZrO prepared by polyacrylamide gel method 2 The powder is dry pressed. The nano-ZrO 2 The powder is made of ZrOCl by using 2 ·8H 2 O and ZrO(NO 3 ) 2 2H 2 The gel precursor prepared from the composite zirconium source composed of O is prepared through gel thermal decomposition steps and crystallization steps to obtain powder particle sizes distributed in the range of 60.4 to 82.6 nm. Among them, the gel precursor reaches 85% to 95% decomposition rate in the gel thermal decomposition step, and 90% to 95% ZrO in the crystallization step 2 From tetragonal phase to monoclinic phase.

[0046] According to a preferred embodiment, ZrOCl in the composite zirconium source 2 ·8H 2 O and ZrO(NO 3 ) 2 2H 2 The molar ratio of O is 0.5:1 to 2:1. The thermal decomposition step of the gel is carried out under the condition of 550°C to 570°C. The crystallization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com