Novel buoyancy type open caisson and construction method thereof

A buoyancy-type caisson technology, applied in caissons, infrastructure engineering, protective devices, etc., can solve the problems of increased foundation burden, insufficient foundation bearing capacity, large settlement of caisson foundation after construction, etc., to prevent water seepage and reduce foundation Stress, the effect of reducing settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

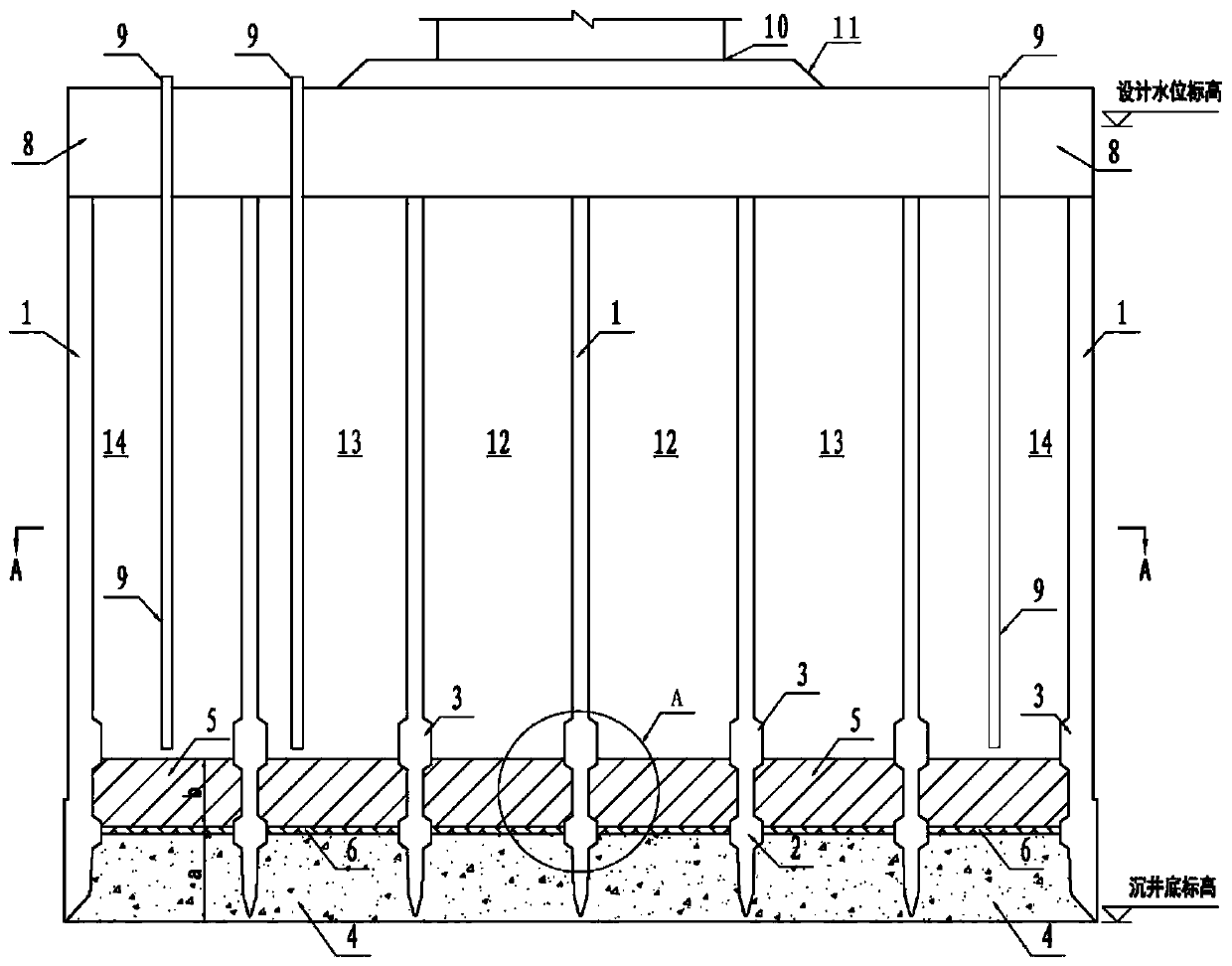

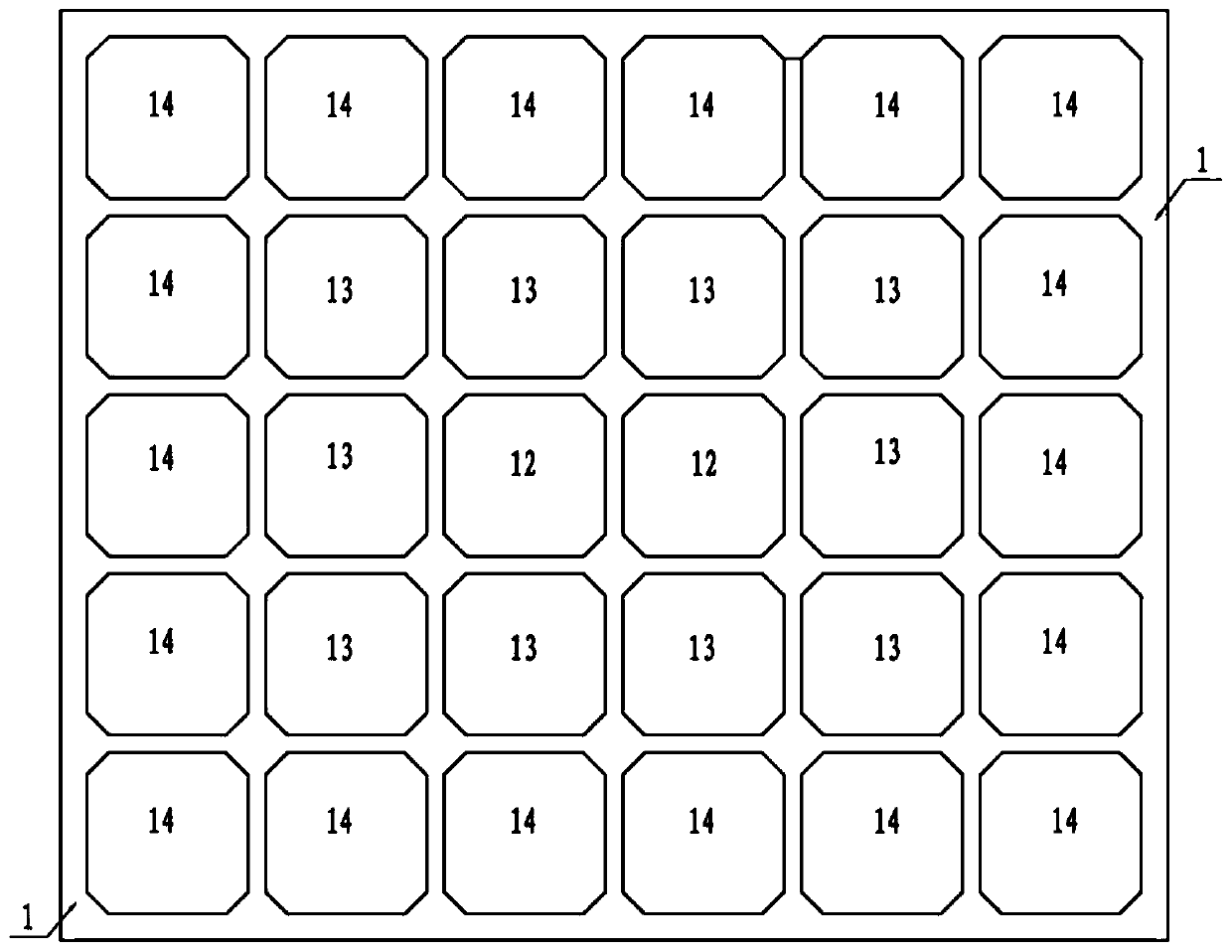

[0051] see figure 1 and figure 2 As shown, the embodiment of the present invention provides a novel buoyancy caisson, comprising:

[0052] In the caisson, there are wellbore units arranged in a matrix, and the wellbore units arranged in a matrix are arranged with multiple circles of wellbore units from the inside to the outside according to the design requirements. The two adjacent wellbore units They are separated by the caisson well wall 1, and the caisson well wall 1 is a vertical and horizontal wall structure. The cross section of the well hole unit is any one or more of rectangle, regular polygon, circle or ellipse. In order to facilitate description and distinction, this embodiment takes a caisson with three circles of wellbore units as an example to describe in detail. A well unit 13 and a third circle of well units 14 . Wherein the number of the well hole units 12 in the first circle is two holes, the number of the well hole units 13 in the second circle is ten ho...

Embodiment 2

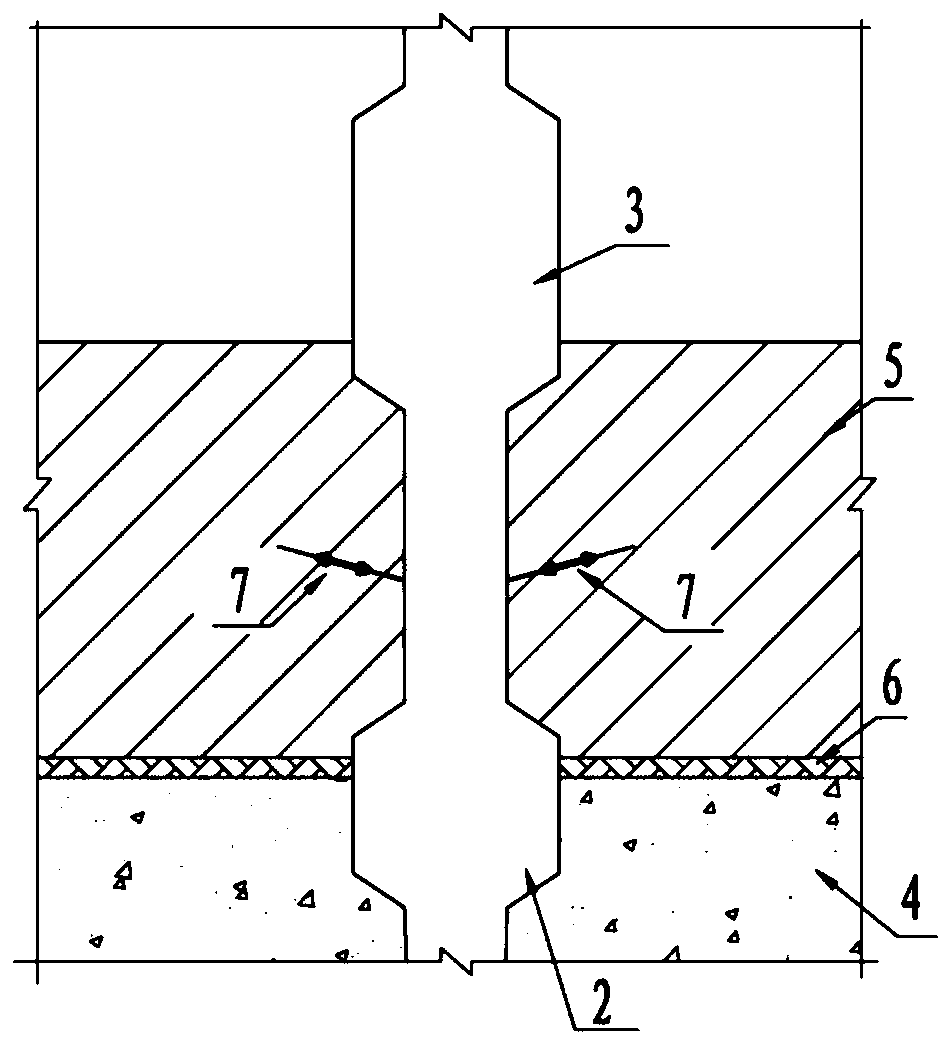

[0062] see figure 1 and image 3 As shown, the embodiment of the present invention provides a new type of buoyant caisson. The difference between this embodiment and Embodiment 1 is that cement-based seepage crystallization is arranged between the bottom sealing concrete slab 4 and the upper waterproof composite dry-beaten concrete bottom slab 5. Permanent waterproof coating 6, the cement-based permeable crystalline waterproof coating 6 is used to prevent the bottom concrete slab 4 from seeping water. The cement-based permeable crystalline waterproof coating 6 can prevent water seepage from the micro-cracks inside the first back-sealing concrete, improve the bonding and water-stopping between the bottom-sealing concrete slab 4 and the caisson well wall 1 and the self-impermeability and water-stopping of the bottom-sealing concrete slab 4 .

[0063] After the cement-based permeable crystalline waterproof coating 6 encounters water, its active chemical substances, driven by the...

Embodiment 3

[0066] see figure 1 and image 3 As shown, the embodiment of the present invention provides a new type of buoyancy caisson. The difference between this embodiment and embodiment 1 is that the upper water-stop composite dry-beaten concrete bottom plate 5 is surrounded by the caisson wall 1 of the well hole unit. A steel edge waterstop 7 is provided, and the steel edge waterstop 7 is used to close the water seepage channel around the upper layer waterstop composite dry-beaten concrete bottom plate 5 along the caisson well wall 1. The steel edge waterstop 7 is arranged inclined upwards, and the steel band of the steel edge waterstop 7 is fixedly connected with the caisson well wall 1 of the well hole unit. The steel edge waterstop 7 is inclined upward at an angle of 30° to 60°, and the steel edge waterstop 7 is poured in the upper waterstop composite dry-beaten concrete floor 5 . The angle of upward inclination of the steel edge waterstop 7 is 30° to 60° to facilitate concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com